150,000 OPSLs and Counting

Coherent milestone demonstrates enduring advantages of optically pumped semiconductor lasers (OPSL).

November 7, 2023 by Coherent

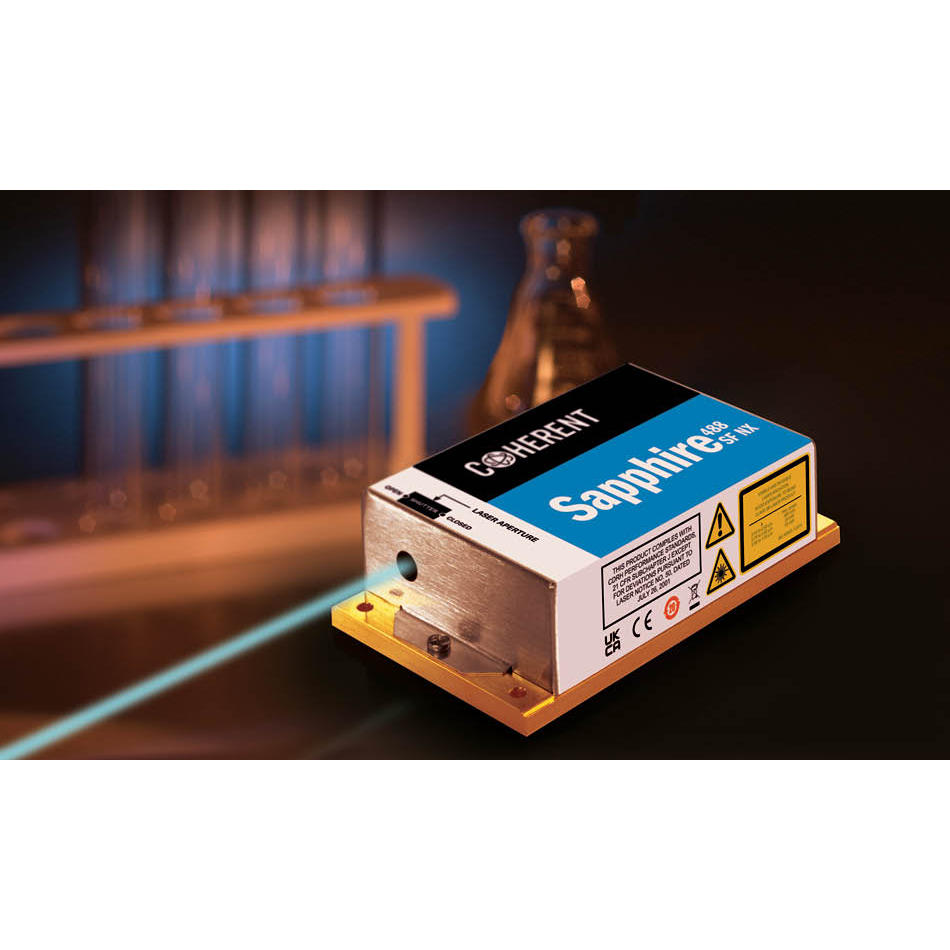

When we shipped our first OPSL back in 2002 – a 488 nm blue Sapphire laser – it was a direct replacement for bulky, power-hungry ion lasers. We believed the unique advantages of this revolutionary new technology could go beyond this and change the landscape for many existing and future applications for visible (and lately ultraviolet) lasers. Well 150,000 OPSLs later, we can report that this technology has indeed proved successful even beyond the most optimistic predictions of two decades ago.

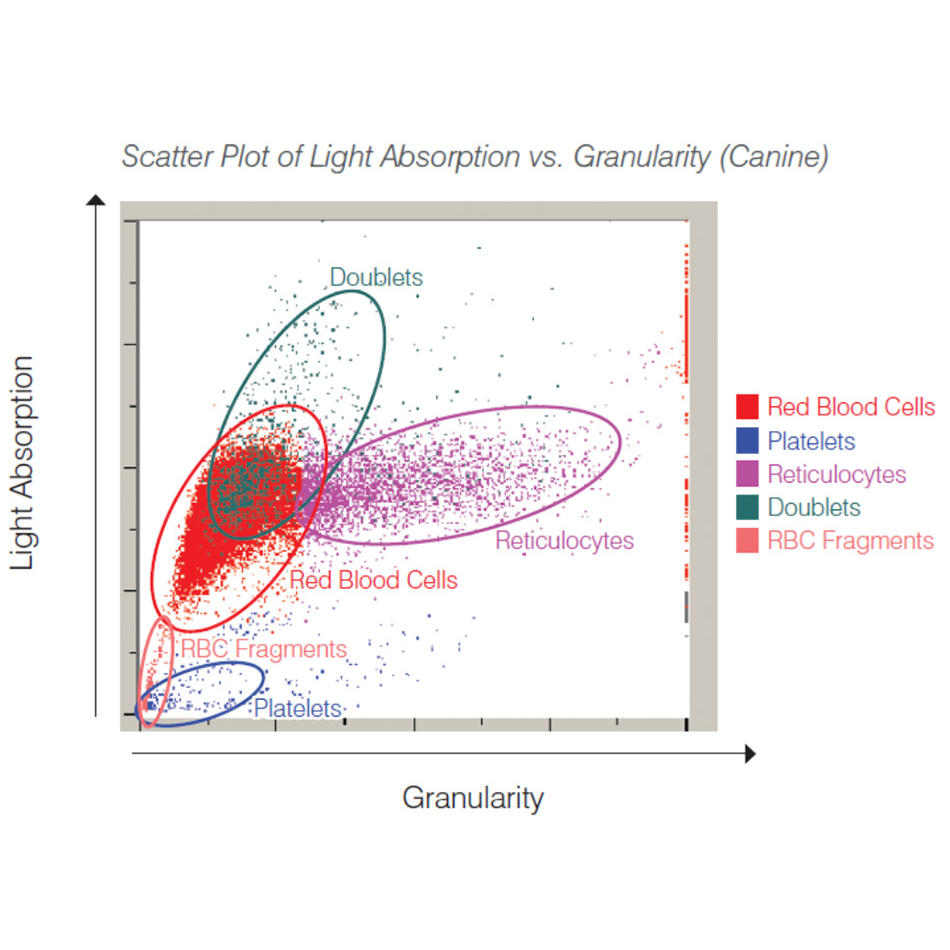

Today our OPSLs can be found in applications ranging from blood analysis (using flow cytometry), to microscopy, genetic sequencing, holography, semiconductor inspection, laser light shows, plus many other examples. And in several of these applications, these OPSLs have become the gold standard.

So what is it about our OPSL technology that accounts for this incredible market success?

It’s not one single thing. Rather, it’s that OPSLs offer a unique combination of advantages. Specifically, the technology is power scalable, enables realization of laser sources for all wavelengths in the range 257 nm – 1154 nm, and delivers inherently low-noise output. The rationale for choosing an OPSL varies from application to application, but it’s usually based on one or more of these key attributes. Let’s take a look at these and put them in the context of one or two applications.

What is an OPSL?

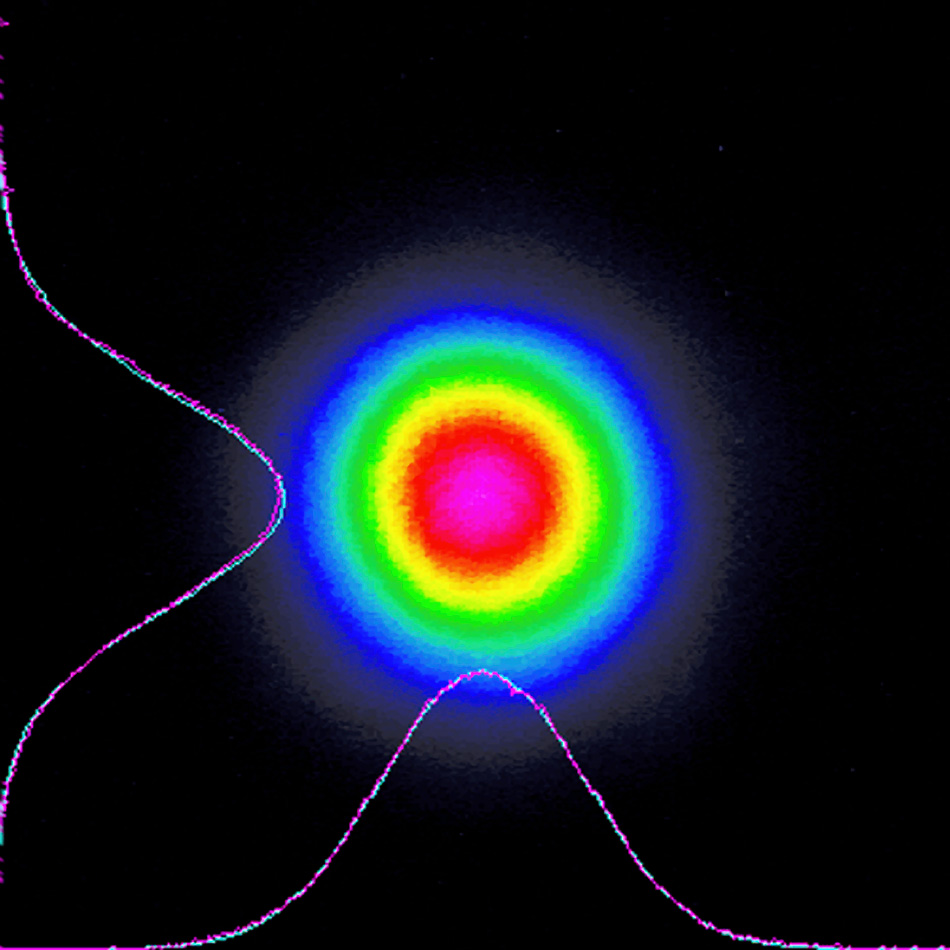

In an OPSL, one or more diode lasers convert electrical power into infrared laser light that is used to pump a thin semiconductor chip, which then emits laser light from its front surface. This thin chip is mounted on a heat sink, enabling very efficient cooling. We build a miniaturized external cavity around this gain chip resulting in a high-performance circular output beam that is easy to focus to a small spot or couple into an optical fiber.

Wavelength scaling. The output wavelength depends on the composition details of the semiconductor gain chip. By changing these details and using harmonic conversion of the resulting output, the laser wavelength can be tailored over a wide range: from 355 nm, throughout the visible and into the infra-red. This is in marked contrast to older laser technologies based on gases or crystals that can only emit at a few arbitrary wavelengths inherent to the physics of the gas or crystal. Bioinstrumentation is a field that really benefits from this wavelength scalability, with OPSLs now offered at wavelengths tailored to optimally match the absorption characteristics of numerous dyes and fluorescent proteins.

Power scaling (and power adjustment). The power of an OPSL design can be readily scaled from milliwatts to tens of watts. In alternative crystal-based lasers (e.g., diode-pumped solid-state, DPSS, lasers), non-uniform heating in the crystal results in something called thermal lensing – the middle is hotter than the actively cooled edge surfaces. The strong focusing/defocusing effects of these thermal gradients limits the power adjustability of crystal-based lasers.

Thermal lensing thus limits the ability to generate higher power and means that the beam characteristics can only be optimized for a narrow power window. In contrast, the output of many OPSLs can be smoothly adjusted all the way from <10% to 100% with no change in beam shape or pointing direction. Light shows represent an application that benefits from power scaling – higher power lasers enable large spectacular outdoor displays. Power adjustment on the other hand is an advantage in many microscopy applications, particularly “super-resolution methods,” where the power needs to be “tweaked” without losing the precise alignment inside the microscope.

Low output noise. In both OPSLs and most crystal (i.e., DPSS) lasers, the gain medium initially produces near infra-red laser light that is efficiently converted to visible or UV wavelengths using harmonic crystals. But with crystal-based lasers, this harmonic generation can result in a type of output noise often called “green-noise.” It was called green noise because it was first identified as a problem in green DPSS lasers. In OPSLs however, the mechanism that generates green noise is completely absent. (In laser physics terms, this is a result of the “zero upper state lifetime of the gain chip.”) Now of course you can make a DPSS that is low-noise, but only by increasing its complexity and cost. However, with an OPSL, the laser is low-noise naturally. Flow cytometry is an application that benefits from this low noise, where it directly increases the data quality, as measured by the so-called Cv of the data.

OBIS lasers deliver M2 ≤1.2 with circular-focused spots.

Anything else? Well in addition to these important technical differentiators, OPSL technology is readily miniaturized, resulting in a high power-to-size ratio, which meets the growing demand from customers looking to miniaturize their systems. (As an example, we offer OBIS CORE lasers as small as 52 x 27 x 13 mm, 2.05 x 1.06 x 0.51 in.). OPSL technology is also electrically efficient, which is increasingly important in the push to greener technology in so many fields. And as already mentioned, the OPSL can generate a nice circular beam. While these additional advantages are not unique to OPSLs, they are positive factors influencing the success of this technology in many of its applications.

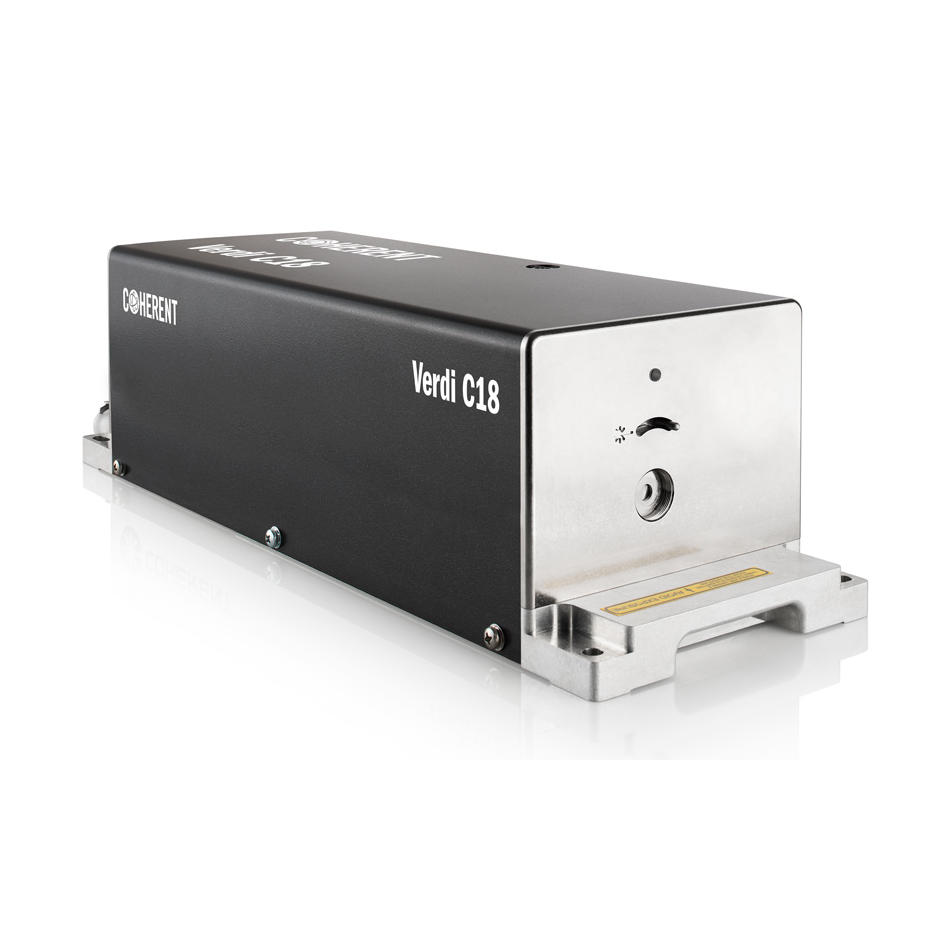

Wavelength and power scalabilities add up to a very versatile laser technology that has enabled it to be specifically configured in different formats for important applications. This is reflected in the breadth of product lines at Coherent based on this technology, which today include several popular families like Sapphire, Verdi, Genesis, Taipan, and OBIS.

OPSL technology is complementary to other technologies such as diode lasers and DPSS lasers, which are preferred in some applications. That’s why Coherent also makes all three laser types. And in product lines like Coherent Verdi and Coherent OBIS, we even offer two or sometimes all three of these technologies in the same package with the same interface.

But if your application needs a CW laser somewhere in the visible or UV spectrum, with output power between milliwatts and multi-watts, and if you need it to be compact, efficient, highly-reliable, and power-adjustable with a circular beam, then an OPSL is the only laser that will give you all this and more.

Discover more about our solutions for bioinstrumentation.