Materials

Ceramics Capabilities

Get unique mechanical, chemical, electrical, and thermal properties of our advanced ceramics and composites to create innovative products.

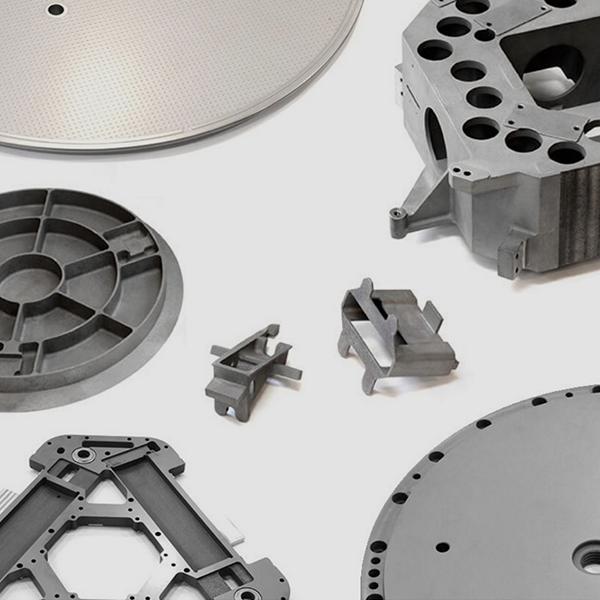

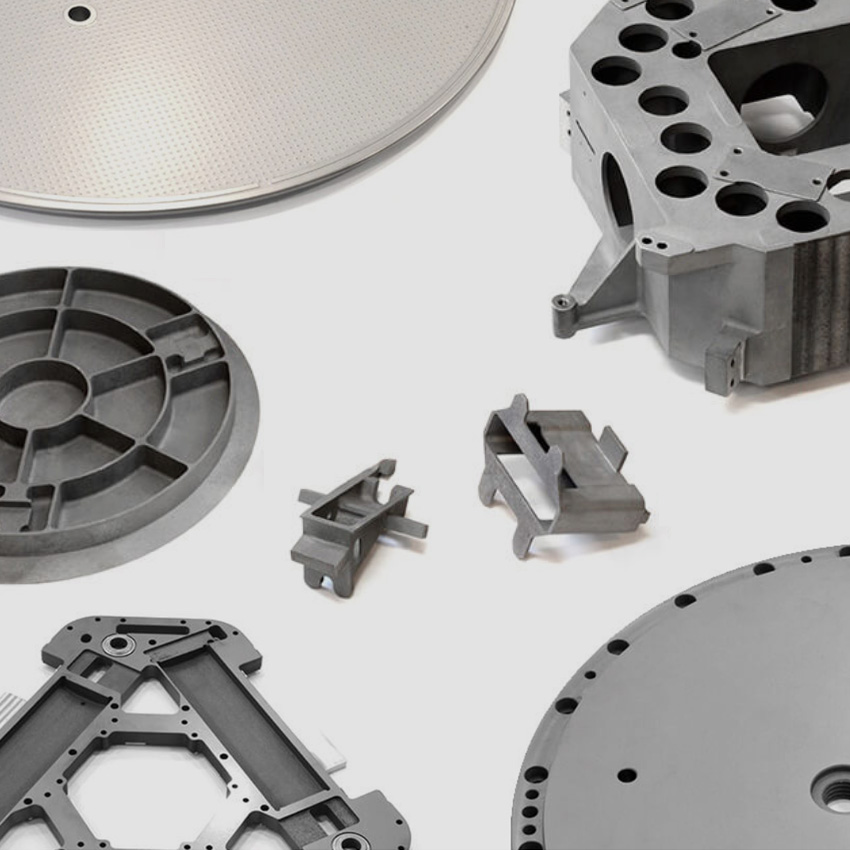

Coherent has extensive capabilities for developing high-performance reaction-bonded ceramics and metal matrix composites - optimized to meet the needs of specific applications - and can reliably fabricate production parts in whatever volume required.

Applications Overview

Semiconductor Equipment Semiconductor tool makers achieve a competitive advantage using composite parts with high flatness, reduced weight, and high thermal conductivity. |

LCD Manufacturing Equipment High-precision structural components for production tooling offer superior strength/stiffness ratios, and can be made in large, complex shapes to tight tolerances. |

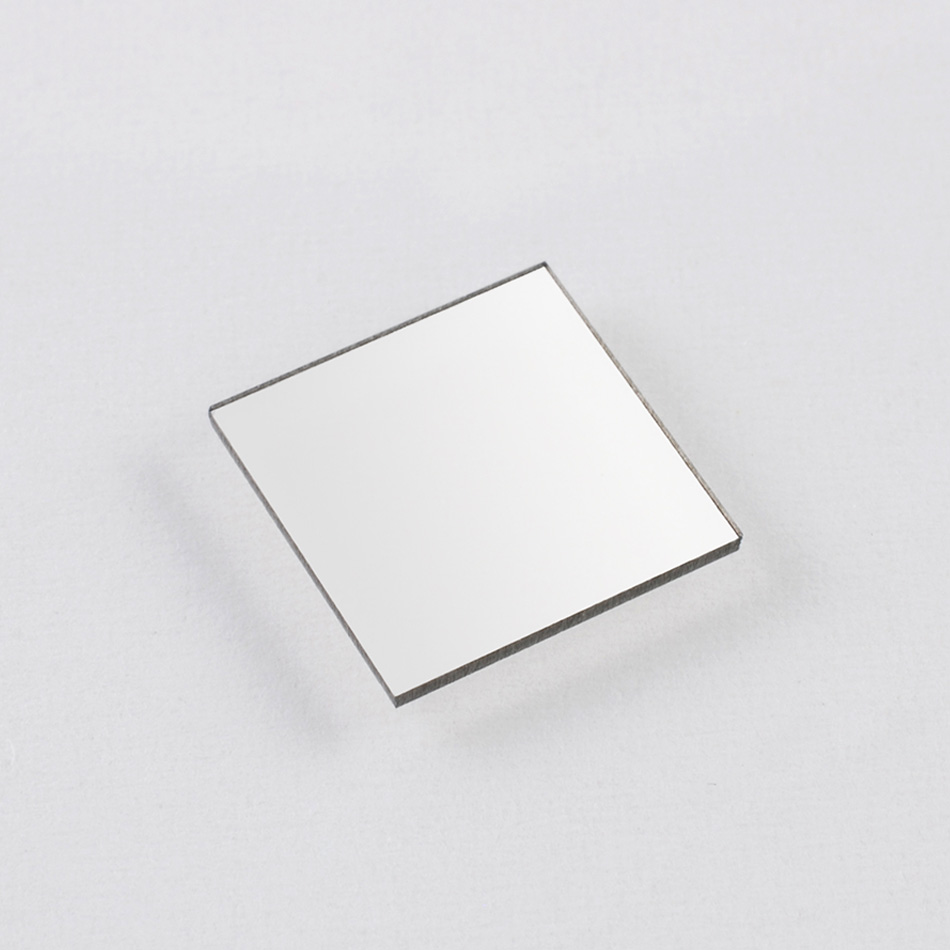

Thermal Management Leading-edge thermal management devices that dissipate and manage heat sources in high-end electronics and related applications. |

Nuclear Power Novel composites cost less than sintered boron carbide and enable neutron absorption systems with fewer seams for easier installation and refurbishment. |

Optics Lightweight, strong mirrors and support structures are used in various optical platforms in defense, aerospace, communications, and precision industrial applications. |

Wear and Refractory Composite components for wear, mining, and refractory uses offer size and shape flexibility, superior strength, minimum weight, and exceptional wear characteristics. |

Armor Ceramics Ceramics meet the needs for personnel protection, vehicle armor, and lightweight/high-strength structures for helicopters. |