Processing Heads

Improve and extend welding, brazing, and cutting capabilities for materials processing applications.

- Increase Precision Achieve higher processing quality, greater accuracy, and improved consistency.

- Optimize Your Process Get better results with products readily configured or customized to meet the exact needs of your specific application.

- Reduce Costs Lower cycle time, eliminate post-processing, and cut rework.

Applications Packages for Increased Productivity

Whether you’re microwelding battery components or cutting 50 mm thick steel plate, these processing heads deliver the combination of performance, reliability, flexibility, and ease-of-use to make your processes run better. They’ll successfully perform the most demanding welding, brazing, and cutting tasks in applications ranging from e-mobility manufacturing and automotive production, through shipbuilding. They accomplish this by mating high quality optics, robust mechanical construction, embedded sensors, and onboard intelligence with powerful, yet easy-to-use software.

Need us to process a material sample? Want to see the results for yourself? We can connect you to a Coherent Applications Lab near you.

Welding Heads and Accessories

Precision welding head for Coherent PowerLine FL or ARM laser welding products that incorporates extensive, advanced beam wobble capabilities. |

Enables welding of dissimilar or “challenging” materials, such as aluminum, stainless steel, and copper, for emobility, and consumer electronics.

|

Provides “smart” patterns ranging from simple wobble to spirals, ellipses and other complex shapes. Pattern size and orientation can be controlled on-the-fly. |

Brings the economy, convenience, and reliability of fiber lasers to new applications. |

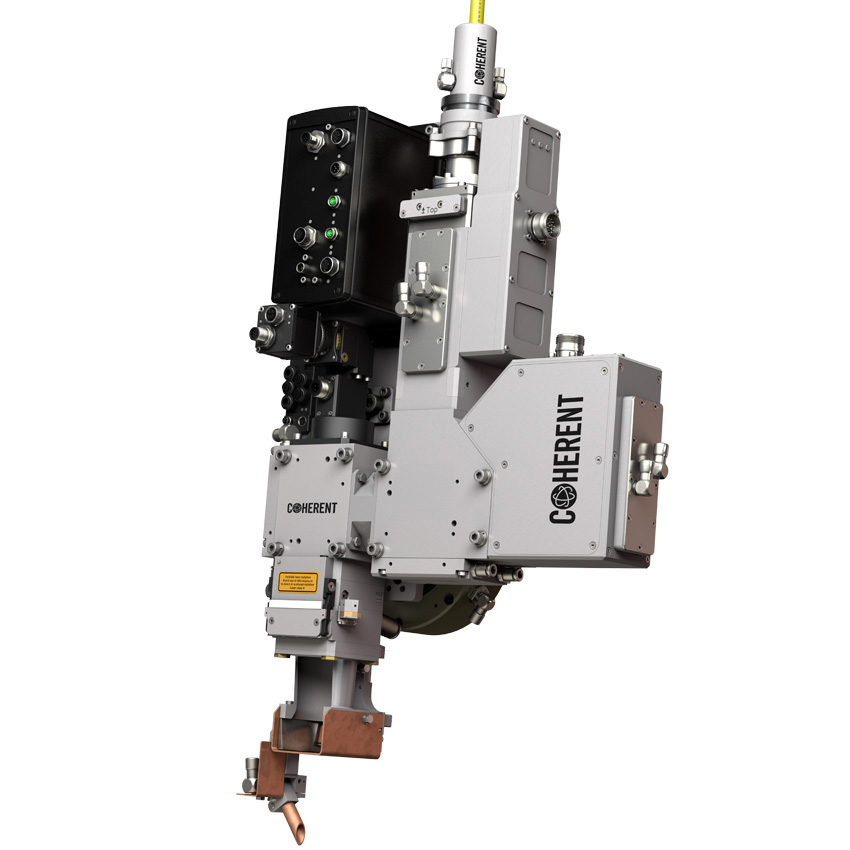

High-performance remote laser welding head, incorporating scanner and F-Theta lens. |

Delivers high quality, reliable welds in the most demanding applications, such as e-mobility manufacturing. |

Works with conventional and ARM fiber lasers up to 8 kW CW, over field sizes to 251 mm x 372 mm. |

Configure it just the way you want with numerous options including cross jets, process monitoring, various magnifications, and vision. |

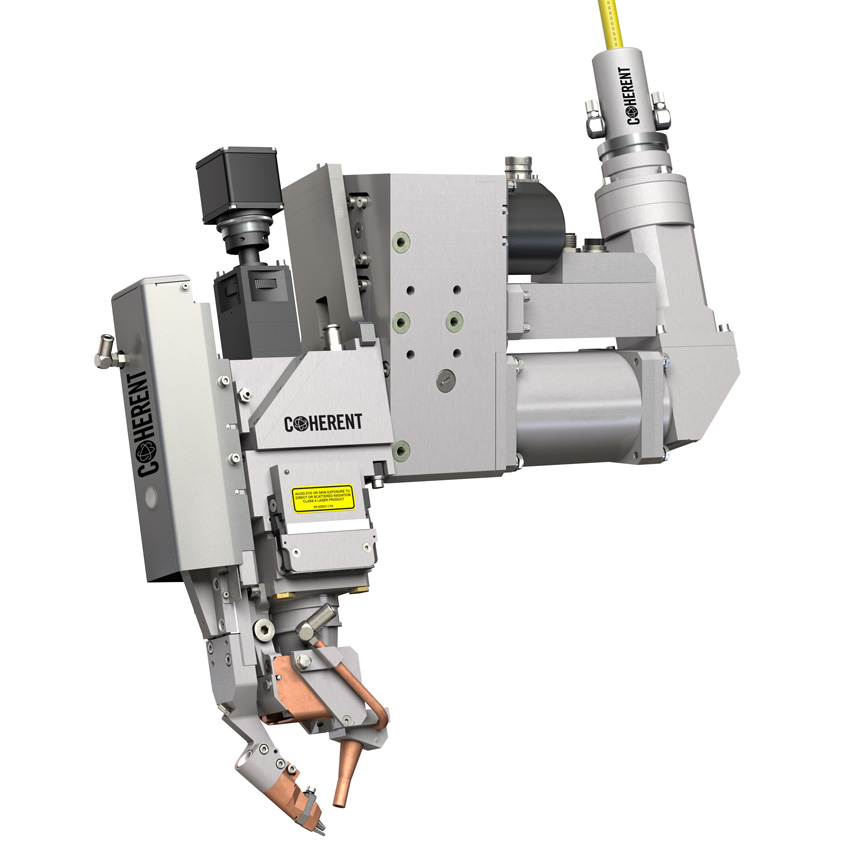

A 3D (x, y, and z beam movement) remote laser welding head offering unmatched capabilities for following complex weld paths. |

Ideal for autobody and hang-on-parts production. Provides high positional accuracy for precision welding of batteries, electric motors, and power train components. |

Covers a large 3D working space (up to 244 mm x 369 mm with 200 mm z range) and can reach any position within milliseconds. |

Seam tracking option automatically follows curved paths and enables fillet welding or butt welding with defined offset values. |

Integrated machine vision solution for Coherent remote welding heads. |

Can be specifically optimized for 3D fillet welding seam tracking, position matching for 2D welding, shape recognition, and hairpin welding. |

Advanced machine vision algorithms deliver precise control, high accuracy, and rapid detection times. |

Graphical interface simplifies task setup, such as defining process limits and error conditions. |

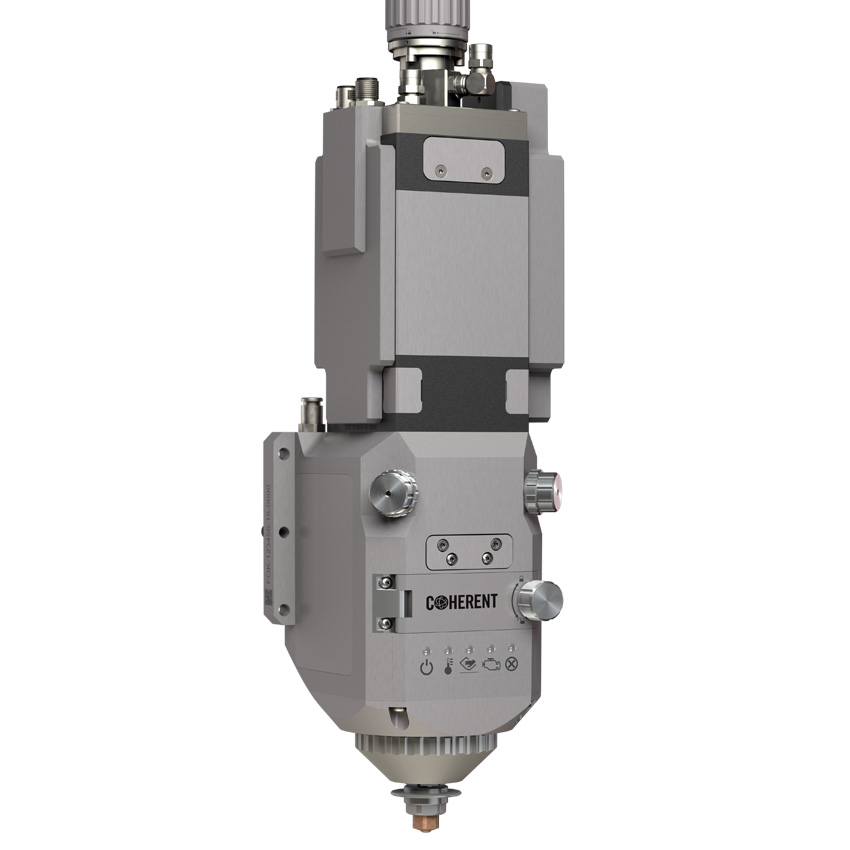

Modular laser processing head for high-power, fiber-coupled lasers of up to 20 kW that delivers exceptional operational reliability. |

Built to deliver unmatched uptime and reliability for high power, industrial welding jobs in auto production, pipe manufacturing, energy, and more. |

Readily configure the exact process head you need with the numerous available modules and options. |

Available with a unique zoom collimation module that accurately maintains any original beam profile, including "top-hat" or ARM beams. |

HIGHmodular Laser Processing Head Tactile seam tracking process heads for wire brazing and welding that deliver high quality results and exceptional reliability. |

Especially useful for demanding welding tasks in auto manufacturing and e-mobility. |

A wide range of options makes it easy to create a process head with exactly the necessary features. |

The ability to continuously adjust zoom and focus on-the-fly takes software-controlled welding to a whole new level of flexibility and productivity. |

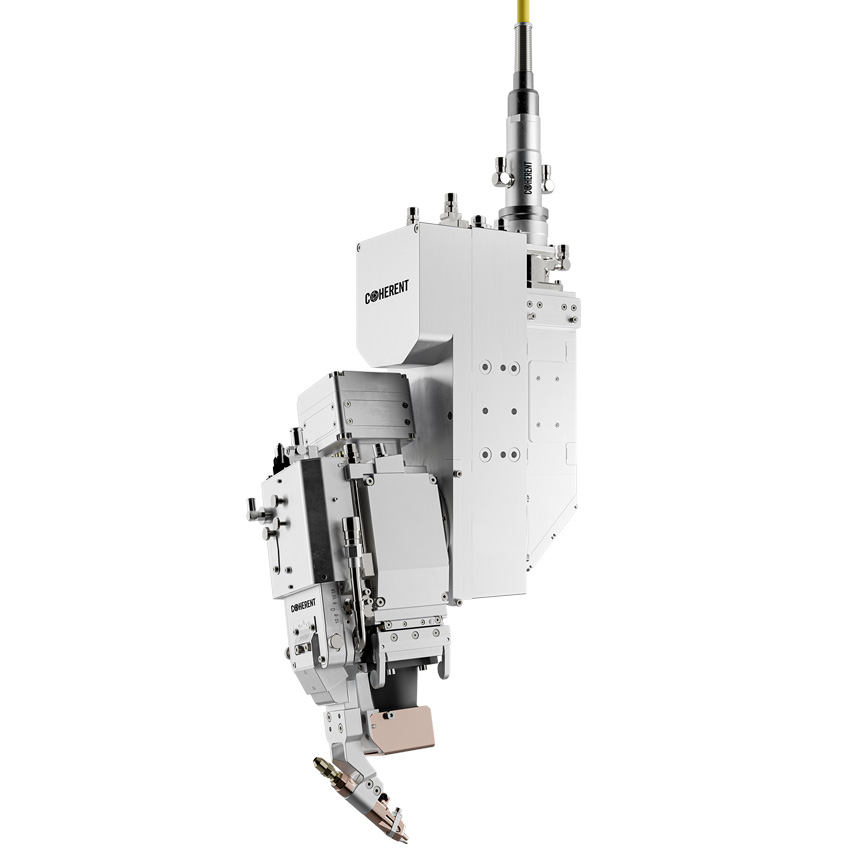

Tactile seam tracking process heads for wire brazing and welding that deliver high quality results and exceptional reliability. |

Ideal for body-in-white welding and brazing tasks, including trunk lids, roofs, and sealing ducts. |

Modular optics offer numerous spot size options, and maintain the input intensity distribution. |

Programmable force control and zoom of magnification and defocusing available. |

Consistently get high-quality brazes and weld joints, even on complex shaped parts, with a tool that is still easy to configure. |

A powerful, flexible system for automotive brazing applications and various wire welding tasks in both body-in-white and e-mobility production. |

Combines advanced sensor and servo technology to deliver precise force control, with an interface that enables rapid setup. |

HIGHtactile can be used with a wide range of fiber-delivered lasers, wire types, and process monitoring systems. |

Cutting Heads and Accessories

A range of products for high-speed fiber laser cutting of sheet metals – such as mild steel, stainless steel, brass, copper, and aluminum. Focus on best cost-to-meter cut ratio. |

Compatible with standard and beam shaping fiber lasers up to a NA of 0.15. Reliable cutting performance in supervised machine environments. |

Integrated sensors report the cutting heads status with the help of a graphical user interface via a Webpage. |

Enables high power cutting application up to 20 kW in CW operation. |

A range of products for use with high power fiber lasers in 2.5D sheet metal cutting applications. Included functionalities offer premium cut quality for mild steel, stainless steel, brass, copper, and aluminum – at thicknesses up to 50 mm. |

Compatible with both standard and beam shaping fiber lasers to a NA of 0.18. Integrated functionalities allow operation in highly automated machines to reliably cut parts in automotive, energy, transportation, white goods, and other manufacturing sectors. |

Unique optical design, with a large focus and zoom range, enables outstanding cutting performance over a wide range of materials and thicknesses. |

Enables high power cutting application up to 30kW in CW operation at unmatched quality. |

Cutting head for Coherent PowerLine FL lasers that produces complex microstructures in metal with reduced taper and at high speed. |

Precision part manufacturing in consumer electronics, medical products and watch making.

|

Patterns include traditional wobble plus spirals, ellipses, and other complex shapes. Particularly well-suited for "on-the-fly" machining of production line parts.

|

Delivers the same results as much more costly lasers.

|

Laser scribing process head including beam delivery optics, a process gas nozzle, and control software. |

Intended for scribing internal combustion engine conrods prior to hydraulic cracking.

|

Scribes one part per second.

|

The only fully integrated laser solution for conrod scribing available.

|

A modular system of collimators, process optics, and accessories for fiber laser welding, cutting, drilling, and scribing applications. |

Flexible, modular, high-precision laser processing head which can be readily configured to deliver optimum results for a wide variety of precision manufacturing tasks. |

Works with lasers of up to 3 kW. |

Options for IR illumination and process viewing cameras available. |

Other Processing Heads

PH50DL Zoom Optic Transforms high-power diode-laser output into a 2D homogenized, top-hat profile, rectangular focused spot, the length and width of which are independently adjustable on-the-fly under software control. |

Applications include heat treating, hardening, cladding, laser assisted bonding, μLED bonding, and tape laying. |

Can change spot size dynamically to optimize laser tempering processes for each application. |

Readily integrated process monitoring options, including pyrometer control, improve quality. |

Replacement Laser Nozzles and Accessories

Replacement Laser Nozzles and Accessories Select from a broad range of products. |

Quick delivery of high-quality replacement nozzles and accessories. |

Compatible with processing heads from every major manufacturer. |

We stock literally 1000s of replacement laser nozzles, all built to OEM specifications. |

Video Spotlight

Reliable Laser Welding of Dissimilar Materials

SmartWeld+ enables precision laser welding of heat-sensitive materials and dissimilar material combinations such as copper to aluminum or steel. It welds these materials with less spatter, porosity, and cracking. This brings the economy, convenience, and reliability of fiber lasers to applications that have previously been challenging for that technology.

Featured Blog

Introducing the SmartSense+ Process Monitoring Accessory

The new SmartSense+ process monitoring solution improves results and cuts costs for many precision laser materials processing tasks.

Ready to Get Started?

Share your contact info and a specialist will reach out.