Materials

Reaction-Bonded SiC

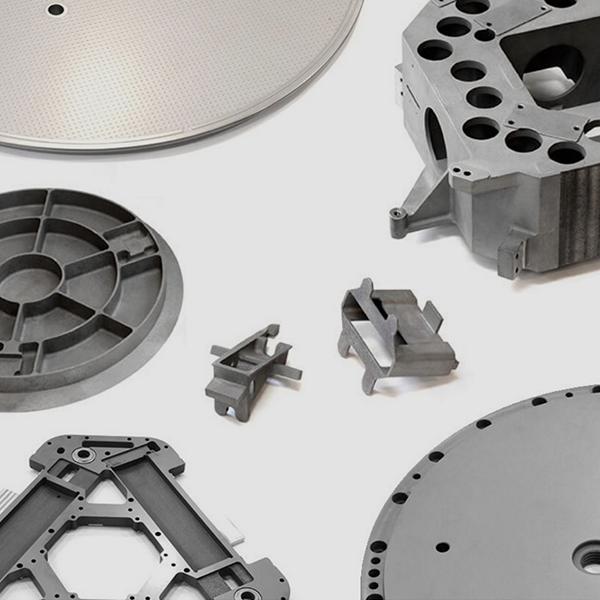

Source RB-SiC components of nearly any size or shape, customized as needed, including high flatness, large infiltration depth, and internal cooling channels.

RB-SiC offers a unique combination of physical characteristics - high-temperature resistance, low CTE, chemical inertness, high strength, and strength-to-weight ratio - for applications in high-voltage electronics, semiconductor tooling, and more.

Reaction Bonded SiC Properties

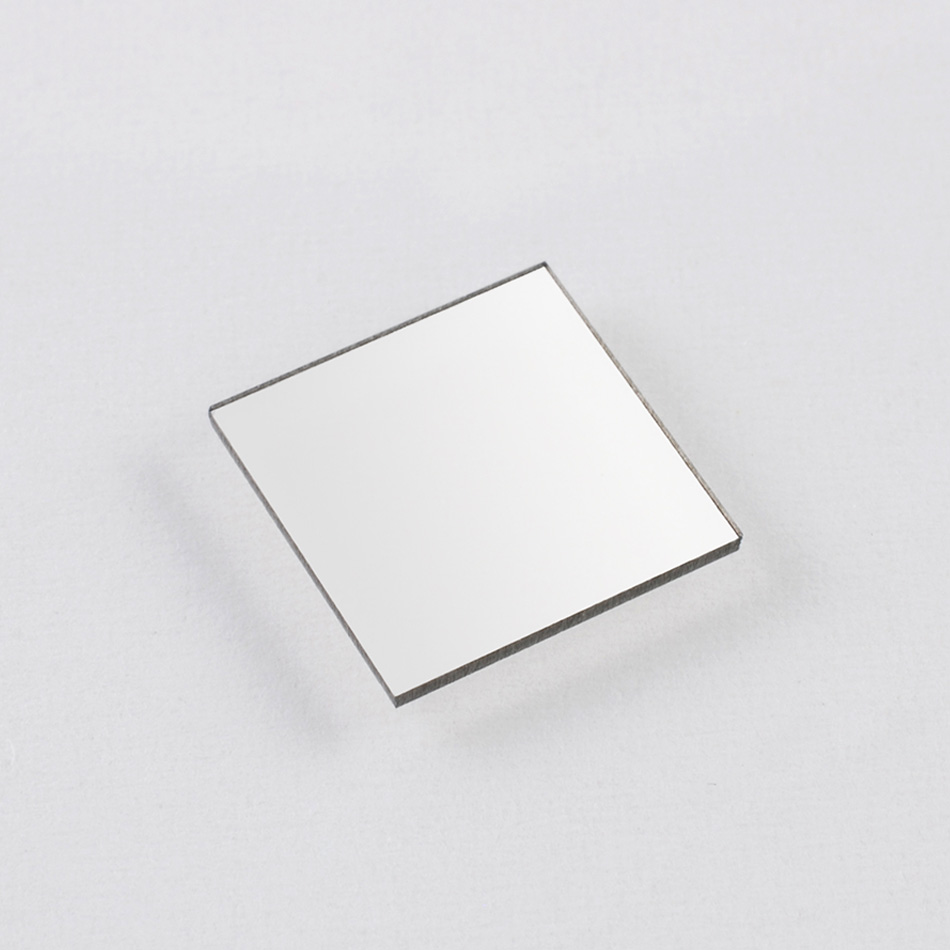

Choose from a range of RB-SiC substrate materials optimized for various mechanical, thermal, and electrical characteristics.

Property |

SSC-702 |

SSC-802 |

SSC-902 |

SSC-HTC |

SSC-FG (Fine-Grained SiSiC) |

HSC-702 (Si/SiC+Al) |

TSC-15 (Si/SiC + Ti) |

RBBC-751 (B4C/SiC/Si) |

SiCAM 700 |

SiCAM 800 |

SiC Content (Vol. %) |

70 |

80 |

90 |

78 |

70 |

70 |

80 |

70B4C 10SiC |

70 |

80 |

Si Content (Vol. %) |

30 |

20 |

10 |

22 |

30 |

30 |

20 |

20 |

30 |

20 |

Bulk Density (g/cc) |

2.95 |

3.00 |

3.12 |

3.02 |

2.94 |

3.01 |

3.13 |

2.56 |

2.95 |

3.00 |

Young’s Modulus (GPa) [E] |

350 |

380 |

410 |

373 |

330 |

330 |

390 |

400 |

345 |

365 |

Poisson’s Ratio |

0.18 |

0.18 |

0.18 |

0.2 |

0.18 |

0.19 |

0.19 |

0.18 |

0.185 |

0.185 |

Flexural Strength (MPa) |

270 |

280 |

280 |

265 |

350 |

275 |

225 |

280 |

280 |

290 |

Fracture Toughness (Mpa-m1/2) |

4 |

4 |

4 |

3.5 |

4 |

5 |

5 |

5 |

3.2 |

3.2 |

CTE (25-100°C) (ppm/K) |

2.9 |

2.9 |

2.7 |

2.9 |

3 |

4.4 |

3 |

4.8 |

3.2 |

3.1 |

Thermal Cond. (W/mK) |

170 |

180 |

190 |

255 |

150 |

200 |

210 |

52 |

177 |

185 |

Specific Heat (J/kg-K) |

680 |

670 |

660 |

670 |

680 |

700 |

670 |

890 |

686 |

674 |

Specific Stiffness (E/ρ) |

119 |

127 |

131 |

- |

112 |

109 |

125 |

156 |

117 |

122 |

Thermal Stability (k/α) |

59 |

62 |

70 |

- |

50 |

45 |

70 |

11 |

55 |

60 |