Ion Implantation

Ion Implanter Disk Refurbishment & Coating

Extend the lifetime, lower the cost-of-ownership, and improve the performance of ion implant tools with Coherent disk refurbishment and coating services.

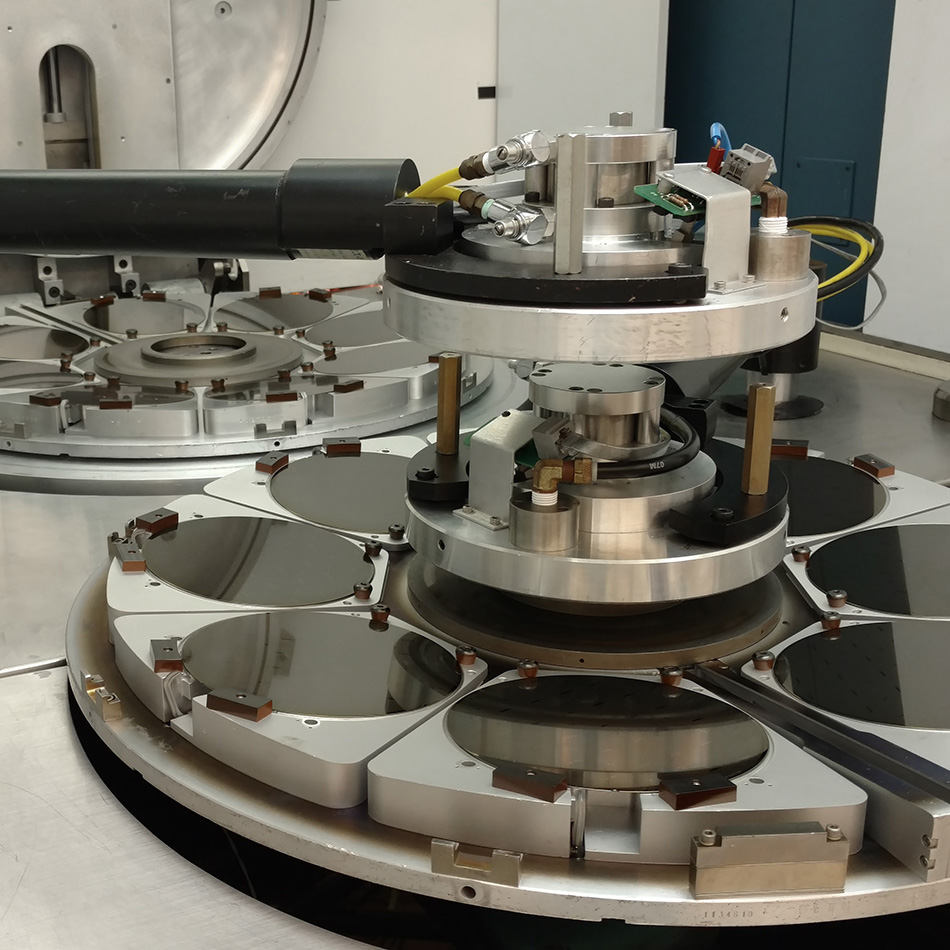

Coherent has extensive capabilities for the repair, refurbishment, and remanufacture of any ion implanter disk or heat sink. This includes all makes and models of batch-processing ion implanters produced since the late 1970s to the present.

Key Capabilities

|

It All Adds Up Our industry-leading innovations enable a 2x lifetime improvement, a 99% decrease in wafer chipping, a 50% decrease in metals contamination, an 80% decrease in fence “wear-grooving” particle generation, and a 30% average cost-of-ownership savings. |

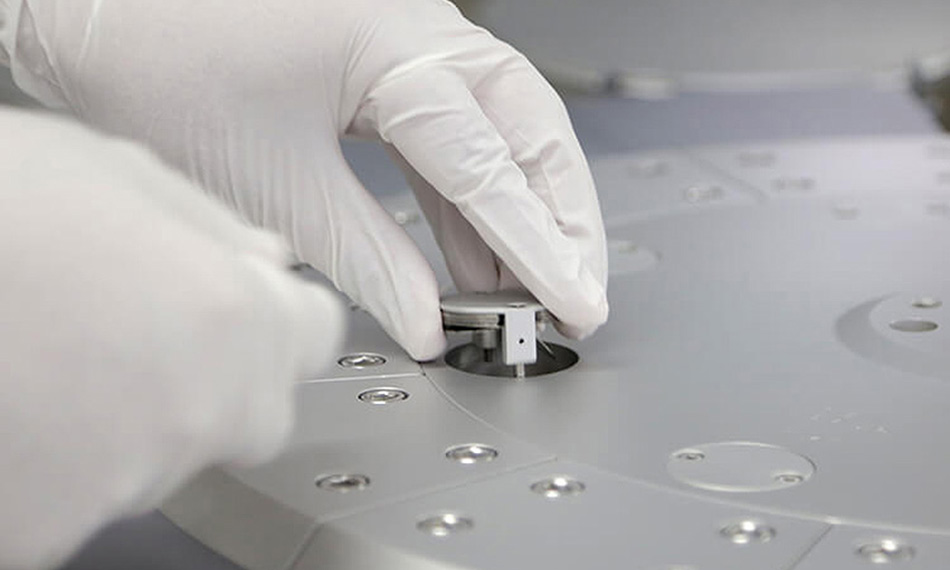

High-Performance Coatings The Coherent low-temperature elastomer pedestal and heat sink coating increases wafer cooling, boosts productivity, and improves pad-to-pad wafer temperature uniformity. |

Torlon Fence Assemblies Utilize high wear resistance Torlon to dramatically improve fence and disk lifetime, substantially decrease wafer chipping, cut fence wear-grooving, and lower metals contamination. |

Improved Fence Design The Coherent high-precision screw-in bearing fence design offers longer lifetime, no asymmetrical fence wear, and eliminates the particle trap that occurs in OEM crimped position components. |

Featured Video

Extend the Life of Your Ion Implantation Tools

Even as semiconductor technology advances, legacy batch ion implanters remain essential in many fabs—and their performance hinges on one critical component: the ion implant disk.

These disks demand precise, periodic refurbishment to maintain wafer quality and equipment reliability. With over 25 years of expertise, Coherent delivers industry-leading refurbishment services—backed by two ISO-9001-certified cleanroom facilities in the US and Taiwan.

From detailed inspections and advanced silicon coatings to elastomer upgrades and precision disk balancing, our process restores your disks to peak performance—boosting uptime, reducing contamination, and protecting your investment.

▶️ Watch the video

📩 Contact us to request a quote and explore how Coherent can keep your batch tools running like new.