Body-in-White

Weld "challenging" materials like galvanized steel, aluminum, and HSS with advanced fiber laser technology.

- Reduce Postprocessing Accomplish zero-gap welding of galvanized steel without spatter or weld pores.

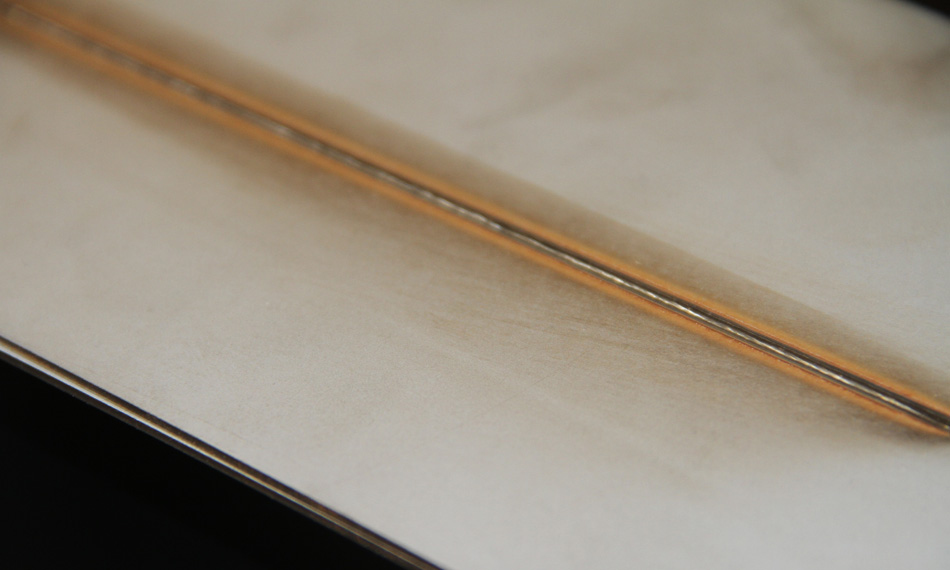

- Eliminate Filler Avoid cracks when welding aluminum 6000 alloys - without filler wire.

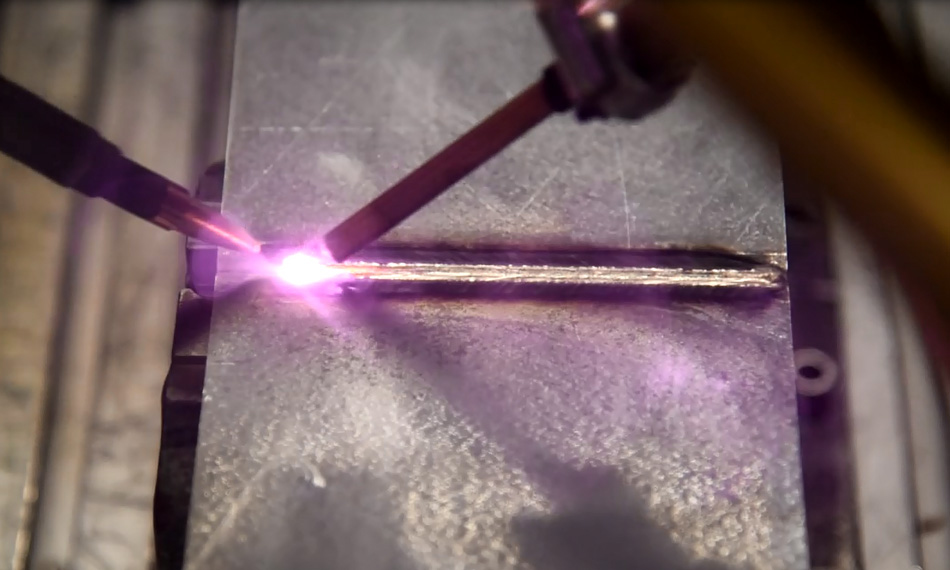

- Prevent Cracking Weld high-strength steels at rapid feed rates with no subsequent cold cracking.

Lighten Up

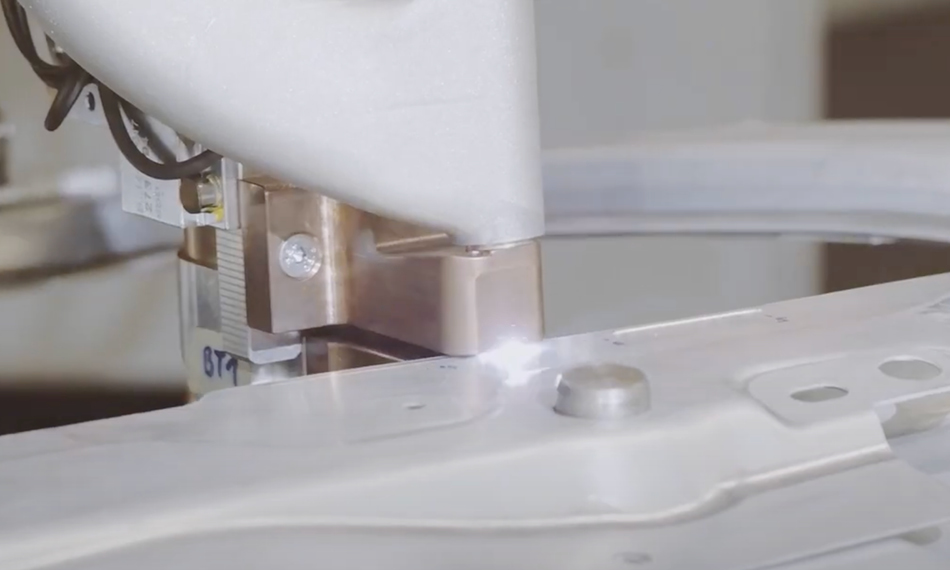

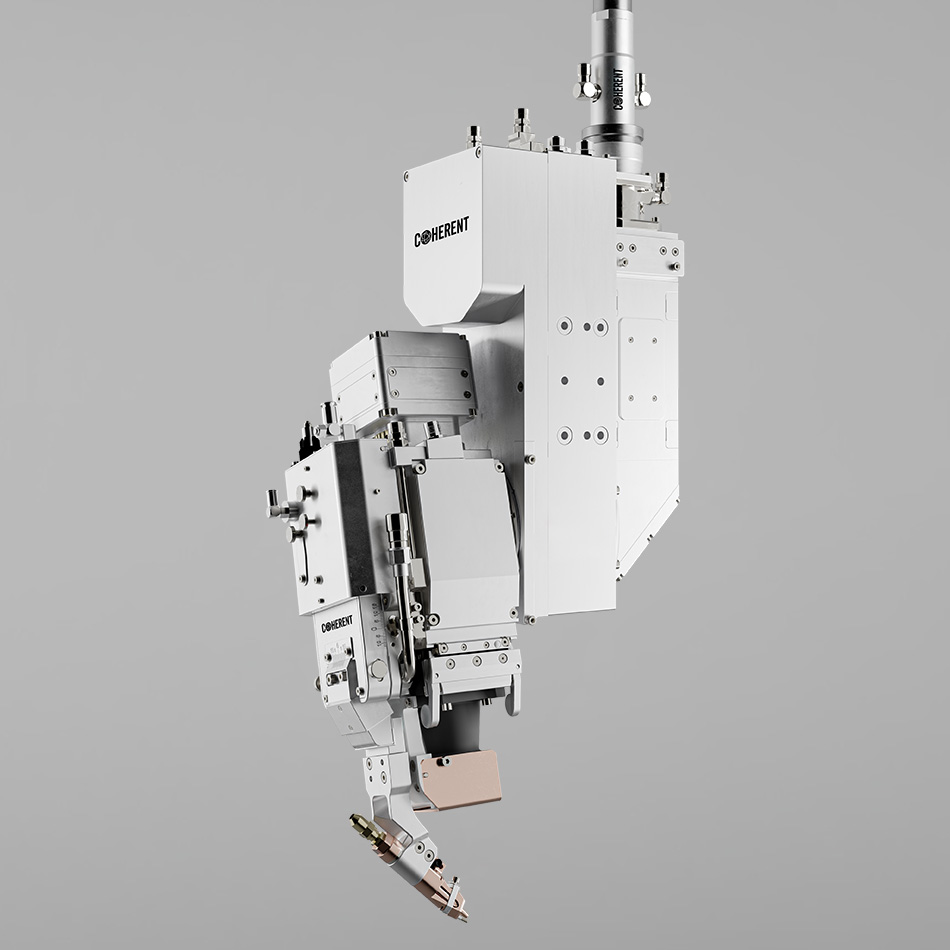

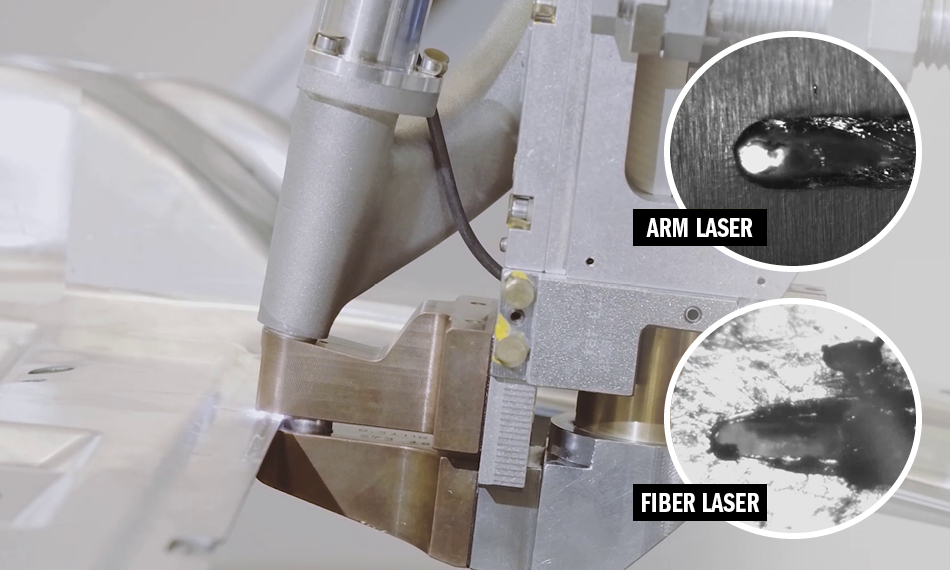

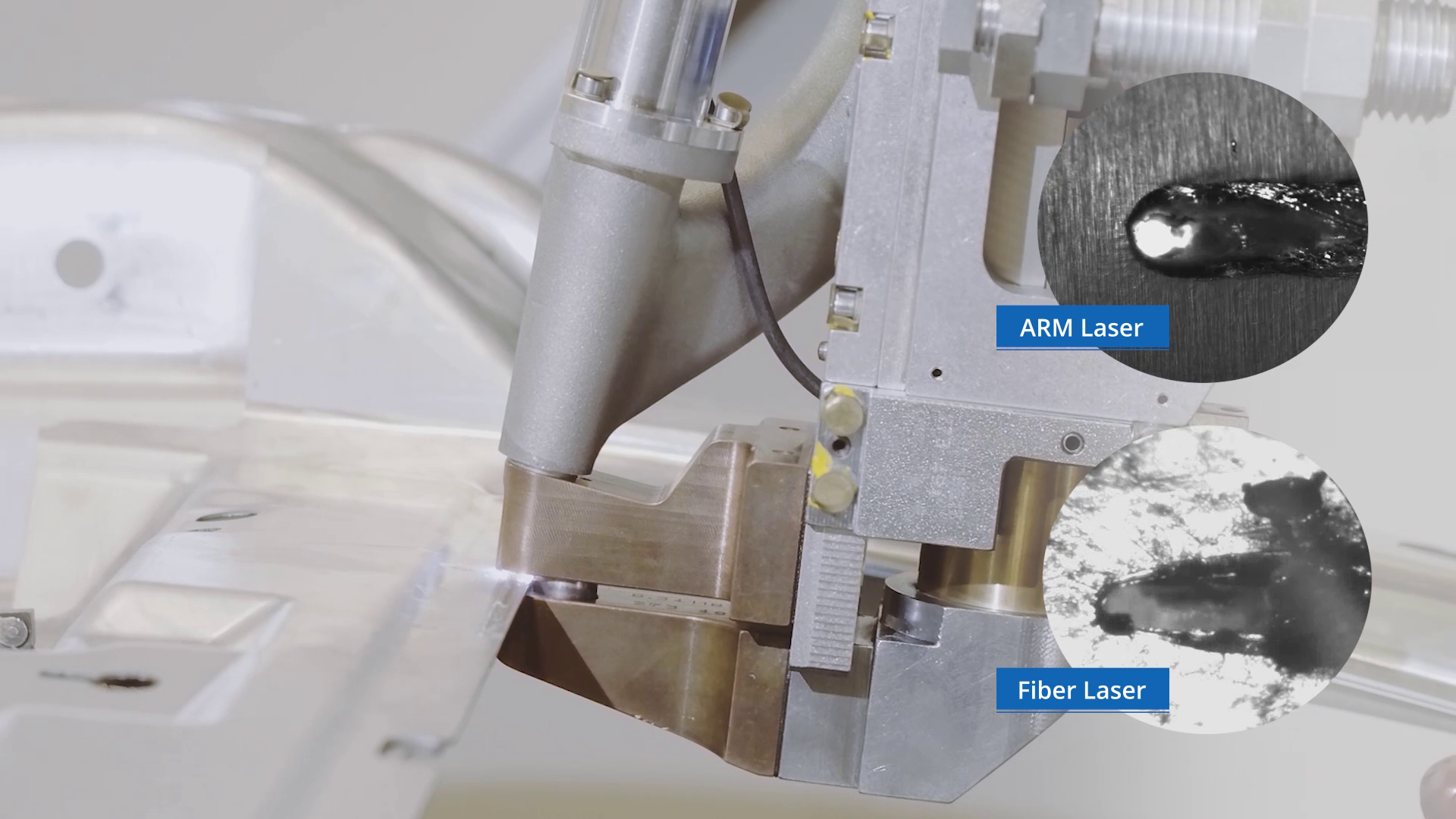

BIW has been revolutionized by the use of new materials that have stiffness and strength similar to traditional steel alloys yet are much lighter. But, welding these materials – like aluminum, high-strength, low-alloy steel (HSLA), and advanced high-strength steel (AHSS) – often creates challenges. Coherent developed Adjustable Ring Mode (ARM) fiber laser technology to deliver the precise control over material heating and cooling needed to successfully weld these materials in volume production.

Let's get started

Please submit some information about yourself, and a product expert will contact you within 2 business days.

Product Applications

More Featured Assets

Body-In-White Products

Video Spotlight

Laser Welding of High-Strength Aluminum to Cast Aluminum

Both high-strength and cast aluminum deliver proven benefits for automotive construction, but also present challenges to laser welding. In particular, both are prone to hot cracking and spattering. These problems are solved utilizing a welding system based on the Coherent ARM laser and the new thyssenkrupp LSK06 laser clamping head.

Featured Blog

How to Get a Head in Automotive Laser Welding

Learn how the Coherent ARM fiber laser is making automotive welding of challenging materials used in body-in-white construction faster, easier, and better.

Resource List

Ready to Get Started?

Share your contact info and a specialist will reach out.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.