CUSTOMER SUCCESS STORY

LASER FRAMEWORK MAKES A MARK IN SIEMENS’ DIGITAL FACTORY

Coherent applications development support and Coherent Laser FrameWork software enable Siemens to successfully implement their ID Link manufacturing program.

There is a growing need for manufacturers to place unique identifying marks on their products. Part of this is to meet government-specified compliance requirements. There’s also an increasing demand from both industrial users and consumers for detailed product traceability.

Governments and industry also want manufacturers to reduce their carbon footprint and to make products using more eco-friendly methods. But these requirements for better traceability and documentation, together with greener production methods, can sometimes conflict. This is especially true when it comes to meeting compliance standards, which often generate a large amount of paper documentation.

Manufacturing leader Siemens has developed an effective way to meet both these needs with their “ID Link” initiative – an all-digital approach to product documentation. And precision laser marking systems from Coherent – which produce high precision marks and integrate seamlessly into the digital factory – are a key enabling technology in bringing the ID Link program into production.

THE MARKING CHALLENGE

Making the ID Link marks in a high-volume production environment presents significant technological challenges. Some of these relate to the mark itself. Specifically, the ID Link QR code contains a fair amount of data. If the product itself is physically small, then this mark must be made at very high resolution to remain readable.

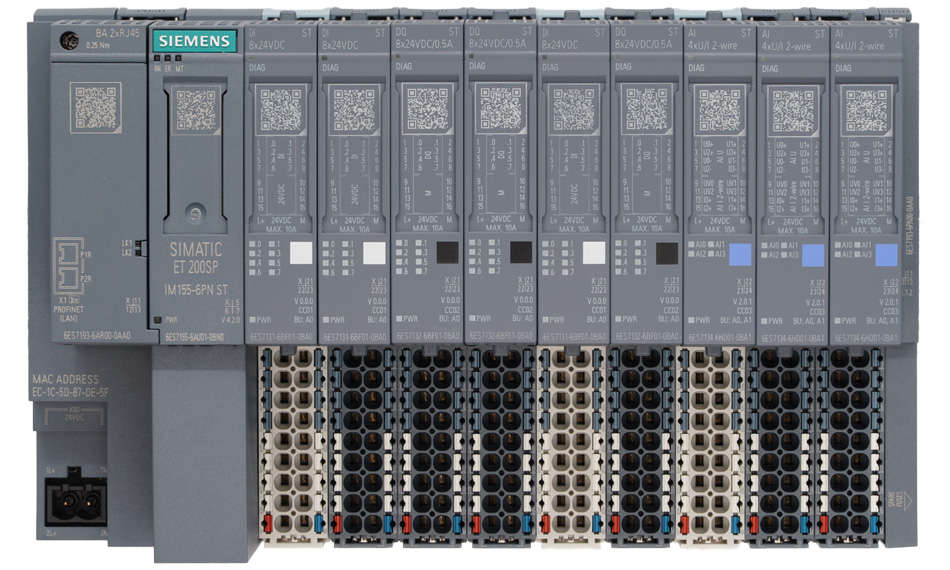

Furthermore, it’s typical to write much more than just the ID Link during the marking operation. There are usually numerous other marks and symbols written at this time. Figure 1 shows a typical product from the Siemens Factory Automation group. It actually gets marked on two sides.

There are a couple of other wrinkles in producing the set of marks required on this particular device. One is that a portion of the face of the device is inset. That is, it’s at a lower level than the rest of the surface. So, the marking system must be able to refocus to deliver a high-resolution mark over the entire surface.

Also, several marks are placed next to LED indicators. This makes the absolute position of the mark important. So each numeral must appear next to the proper LED. Furthermore, Siemens wants good unit-to-unit consistency – the marks should always appear the same distance from the LED on every unit.

The difficulty in producing these marks is compounded because many Siemens industrial automation products are made in extremely high volume. Therefore, the takt time for a given process (like marking all these identifiers) must be short. Literally just a few seconds.

The other challenge in implementing ID Link in production is software related. In particular, the marking system must interface with other factory automation and Manufacturing Execution Systems (MES) to receive the information necessary to properly identify the part, and then get the specific information (serial number, etc.) for the mark itself. After marking, the laser system must transmit data about the finished part back to the production control software.

MARKING SYSTEM DEVELOPMENT

“We never considered using any non-laser marking technology for this application,” notes Tobias Mittnacht, ID Link Project Manager at Siemens. “We’re producing a high-value product in large quantities, and we want a legible mark that is cosmetically attractive and matches the quality and perceived value of our part. Plus, the mark must be indelible; these parts are handled quite a bit by users, and we don’t want the mark coming off or smudging.

“Additionally, we need to be able to produce these marks quickly, and rapidly change the mark pattern as different part variations come down the production line. Finally, to fully integrate marking into our digital factory, we need to have the marking system automatically generate each unique mark based on data coming from our PLM System. Laser marking is the only technology that delivers on all these requirements,” adds Herbert Biller.

Producing the actual mark in this case requires removing a thin layer of dark thermoplastic to reveal a lighter-colored plastic beneath it. An Nd:YVO4 laser operating in the infrared is an ideal source for this task. In some cases where the particular polymer doesn’t absorb well in the IR, a UV Nd:YVO4 laser is used instead.

The hardware solution presented by Coherent for this application was a PowerLine E25 laser marking engine. This integrates an Nd:YVO4 laser with an xy galvanometer scanner and F-theta scan lens, plus all the necessary control electronics. The actual production system uses two lasers to independently mark on two sides of the device simultaneously. A fast-focusing module is used in the scanner that marks the surface having two different levels. This enables the scanner to refocus and make the sharpest possible mark no matter what the surface height.

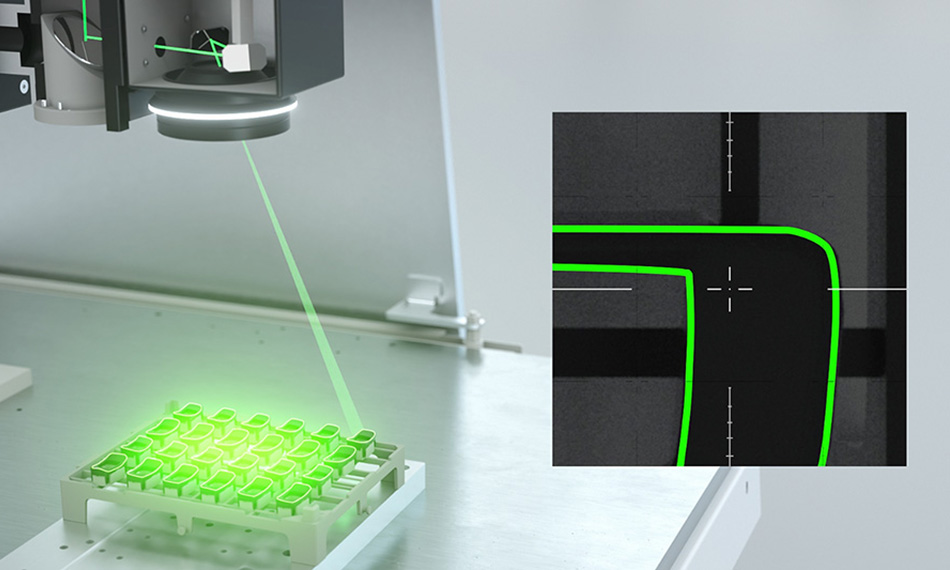

A key element for achieving the required mark placement accuracy is the integrated, through-the-lens (TTL) vision system PartVision. It examines and verifies the part prior to marking and tells the scanner how to adjust for variations in position caused by material handling and part transport tolerances.

PartVision is necessary because it avoids any mismatch between the view of the vision system and that of the laser scanner. This same vision system is used for post-marking inspection.

INTEGRATING WITH THE DIGITAL FACTORY

“We chose to partner with Coherent because they are the only laser company that offers the degree of vertical integration that we require. In particular, this means providing the laser hardware and applications assistance for refining the process recipes. And it includes having the capabilities and willingness to develop all the layers of software required to integrate the marker smoothly into our digital factory,” reports Bernhard Mayer, Head of New Machine & New Product Introduction.

“I think Coherent were able to achieve this software integration so quickly because of Laser FrameWork. It’s much more than just a user interface and environment for rapidly defining new process recipes. It truly is a framework that enables connectivity with other elements in the digital factory.”

“The other thing that Laser FrameWork offers us is seamless integration of the vision system. Mark placement accuracy is really important to us, plus very high-speed operation in our application. In our experience, it’s very difficult to achieve these when you add a vision system from a third-party vendor to a laser marker. It takes an embedded vision system to deliver the level of on-demand accuracy we require.”

Tobias Mittnacht points out that, “One example of Laser FrameWork flexibility, plus the willingness of Coherent to support our specific needs, showed up in implementing the surrounding frame for the ID Link. This frame must adapt dynamically with the QR code size. Coherent was the first laser manufacturer who delivered this capability within their software.”

Herbert Biller adds, “A final bonus of Laser FrameWork is that it’s backwards compatible. We have a large installed base of Coherent marking systems. We’re able to upgrade these to our current standards with Laser FrameWork. This saves us a tremendous capital expense.”

Digital manufacturing is becoming increasingly popular because it enables companies to respond more quickly to changing demands, increases production efficiency, reduces labor content, and improves quality. Coherent Laser FrameWork enables Coherent laser machines to operate successfully in the digital environment. And support from Coherent in developing applications based on Laser FrameWork can rapidly get these solutions into production.

"The solution we got from Coherent is unique, and no other laser company could match it. They were the first provider of marking systems that could meet the demands of our digital factory."

THE ID LINK CONCEPT

The International Electrochemical Commission has formulated a standard (IEC 61406-1) for product identification that is quickly gaining global use. It specifies that each individual product unit must have a unique mark that provides a link (URL) to digital information about that product.

The Siemens ID Link was developed to meet this standard and provides an eco-friendly approach to meeting product labeling, documentation, and compliance requirements. An ID Link is a unique QR code that forms the “digital nameplate” of the product. It contains information including the part number, serial number, and even the MAC address for products used in the IOT (internet of things). The customer can easily identify the ID Link because it is always surrounded by a standardized square frame with a triangular corner on the lower right side.

Scanning this ID Link QR code takes the user to a web page which contains comprehensive product information. This can include datasheets, manuals, calibration protocols, compliance certifications, downloads, Siemens product contacts, and even information on the product’s carbon footprint.

Providing all this information digitally eliminates a virtual mountain of associated paperwork. Plus, it makes that everything immediately accessible to the user. There’s never a need to search for a misplaced manual.

Currently, Siemens is working to implement ID Link on all the products manufactured by the company’s two largest divisions – Digital Industries and Smart Infrastructure. The initiative is in pilot production at a Siemens factory in Amberg, Germany; this facility belongs to the Factory Automation business unit within the Digital Industries division. The Factory Automation plant manufactures industrial automation products.

Figure 1: Marks produced on the Siemens SIMATIC ET 200SP interface module. Much of this same information is repeated on the side of the device.

Figure 2: The Coherent PowerLine E25 integrates an Nd:YVO4 laser, high-performance scanning, and beam delivery optics, drive electronics, and powerful control software to yield a fast, flexible, and accurate marking platform.

Figure 3: Vision and pattern recognition capabilities included in Laser FrameWork, combined with a TTL vision system, ensure mark placement accuracy.