How to Get a Head in Automotive Laser Welding

Automotive welding is now much easier to implement using a completely new type of process head together with advanced Coherent ARM fiber laser technology.

August 19, 2021 by Coherent

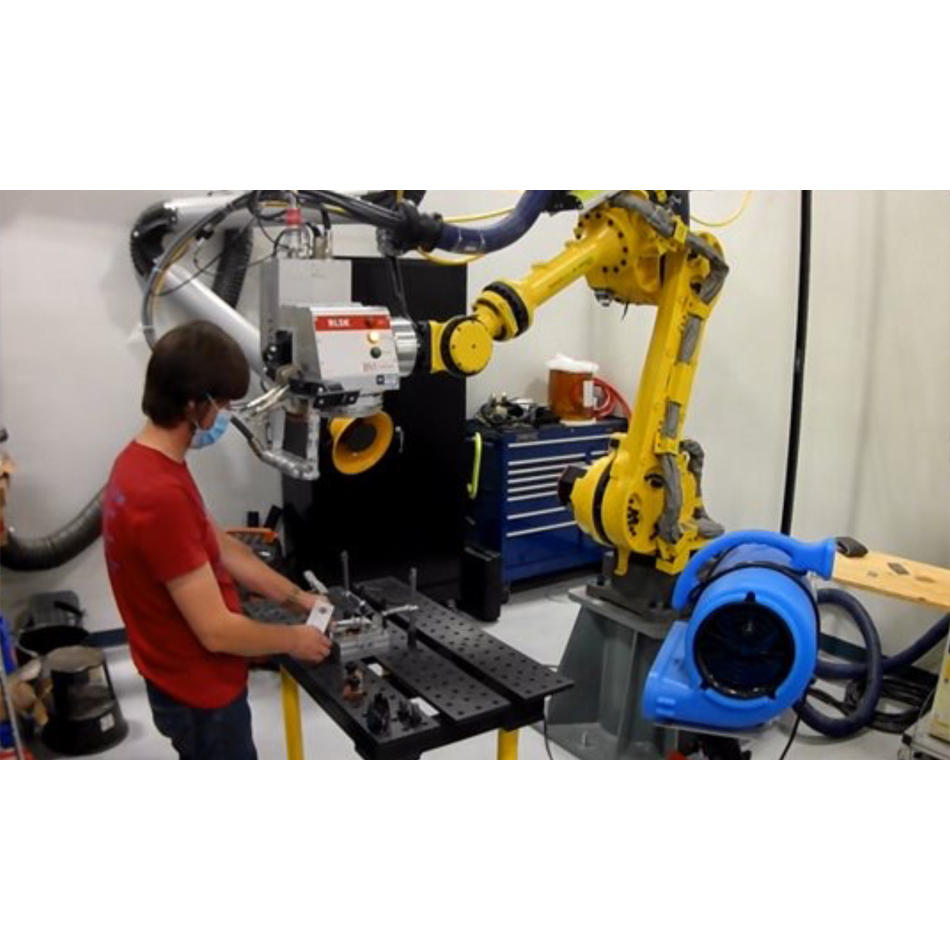

Welding some of the most challenging materials, including aluminum and galvanized steel, is faster, easier, and better than ever before with a solution that combines the latest technology from Coherent and German manufacturing powerhouse thyssenkrupp Automotive Body Solutions. Specifically, this new product mates a Coherent Adjustable Ring Mode (ARM) laser and an advanced thyssenkrupp LSK 06 process head to deliver key advantages in terms of weld quality, practical implementation, and safety.

Go with the flow

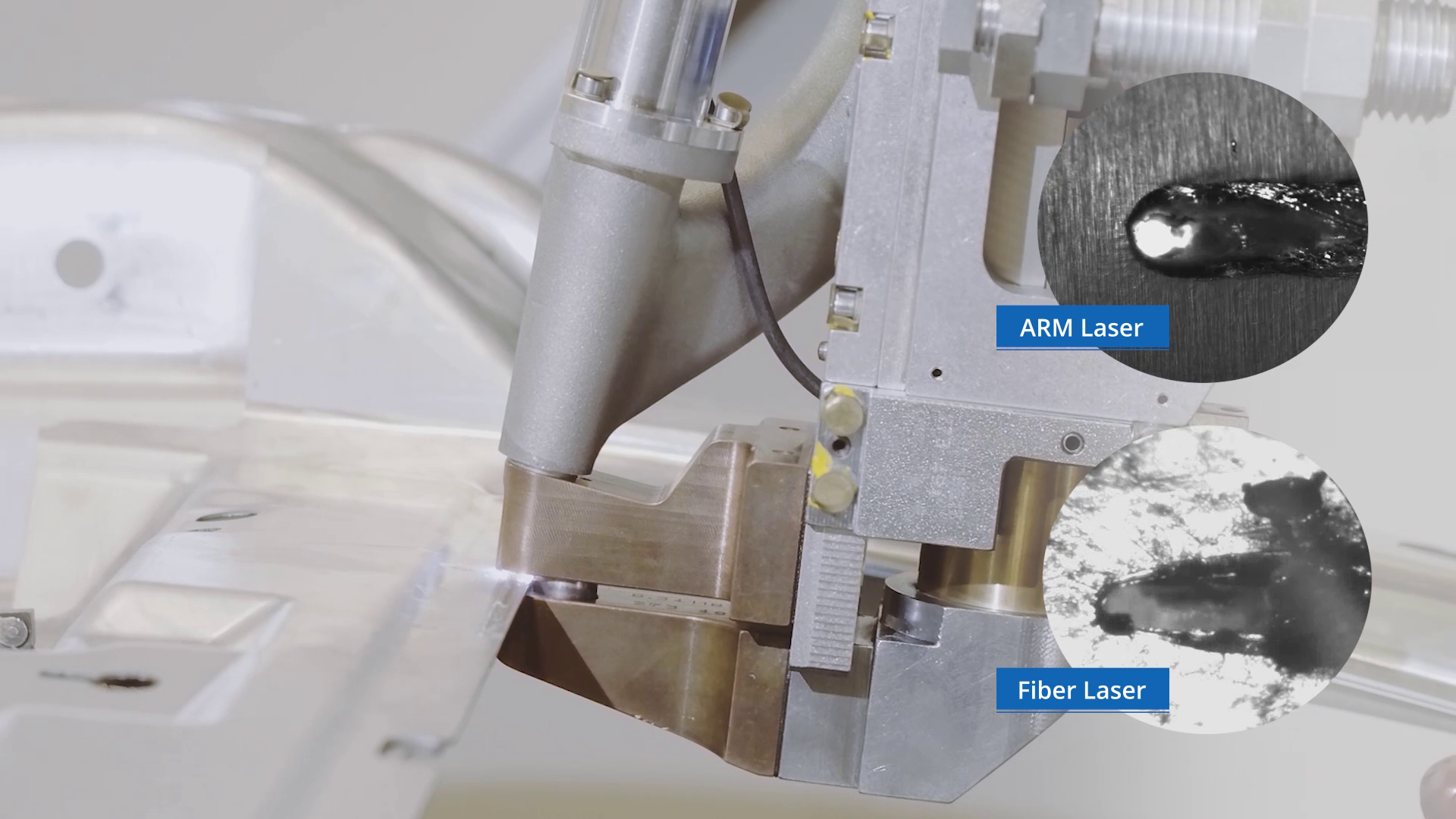

One of the biggest innovations in the LSK 06 process head is a completely novel approach to gas flow. Traditional welding process heads utilize a powerful gas cross jet to prevent spatter from building up on the protective window. But, this does nothing to assist the weld process itself, and in fact, creates unwanted turbulence that destabilizes the melt pool.

In contrast, the LSK 06 is built to mechanically surround and enclose the entire weld area; it actually clamps down around the workpiece and forms a fairly tight seal. Then, a tubing system within the process headsets up a laminar flow of fume extraction right from the area around the welding process itself. This increases fume removal efficiency and also stabilizes and improves melt pool dynamics.

When combined with the precise spatial control over laser power delivery provided by the unique, coaxial beam ARM laser, the result is spatter and crack-free welding, better process consistency, and a wider process window.

A force to be reckoned with

The physical clamping action of the LSK 06 process head also eliminates the need for costly and complex fixtures. It simply clamps the parts together, with a force that can range for 100 N to 1000 N, in order to get the exact part fit up needed for optimum welding results. And, this force is maintained and adjusted on the fly as needed, as the process head moves along the weld seam. The result is a better fit and reduced cycle time because you’re eliminating the need to place the parts in a complex fixture and then precisely adjust the clamping.

A first-class laser system

You get some other important practical advantages by completely enclosing the weld area with the process head. First of all, it yields a Class I laser system. This, together with the fact that all the process fumes are contained and extracted, significantly enhances system safety.

A Class I laser system also means you don’t need a protection booth around the welder. This saves production floor space and cost, and improves accessibility for both normal usage and maintenance. It even makes it easier to retrofit the system into an existing production line.

The use of materials that are difficult to weld, like aluminum, high-strength steel, and galvanized steel, is increasing as automotive manufacturers work to produce lighter, more efficient, and safer cars. Together, the thyssenkrupp LSK 06 process head and Coherent ARM fiber laser can tackle the toughest of these welding challenges, delivering better results while simultaneously simplifying the process. And, tests at Coherent even show that the increased process window this welding system allows reduces the amount of laser power required. And, that saves money, too.

Watch this video to get a glimpse of this revolutionary laser system in action when welding cast aluminum to high-strength aluminum for a body-in-white application.

Related Resources