CUSTOMER SUCCESS STORY

SmartWeld+ Fills the Gaps in Production Welding

When production automation experts teamtechnik were contracted to develop a production welding system, they looked to Coherent to supply the laser expertise. They ended up with a partner who helps them provide their customer with ongoing support.

Production automation expert teamtechnik supplies everything from manual through fully automatic turnkey systems for manufacturing, assembly, and testing. Their expertise spans a huge range of technologies, including part handling, various testing methods, and joining processes, mainly for the e-mobility industry. In 2019, they were asked to develop a production welding system by a manufacturer of battery packs for handheld power tools.

In particular, teamtechnik was tasked with providing automated solutions for welding 11 different joints. These included joining a variety of materials together. Because they didn’t have extensive in-house expertise in laser welding, and so many processes had to be developed in short order, they reached out to Coherent Labs to assist them.

A smarter way to weld

The Coherent team was supplied with material samples. A series of tests readily demonstrated that all these processes could be successfully accomplished with the Coherent SmartWeld+ processing head, coupled with a 1 kW, single-mode fiber laser (the HighLight FL1000CSM).

SmartWeld+ is a specialized welding tool that incorporates an advanced form of beam shaping, including a wide variety of oscillation patterns. It also enables precise control of delivered laser energy during the weld process. Together this allows the width, depth, and penetration profile of the weld seam to be carefully managed. It’s particularly useful for joining heat-sensitive materials and dissimilar material combinations, such as copper to aluminum or steel. Also, it can weld highly reflective or volatile materials with less spatter, porosity, and cracking.

Difficult materials

SmartWeld+ even enables processing of “difficult” materials – that is, those that aren’t traditionally compatible with laser welding. Some of the materials utilized in the battery pack construction fell into this category.

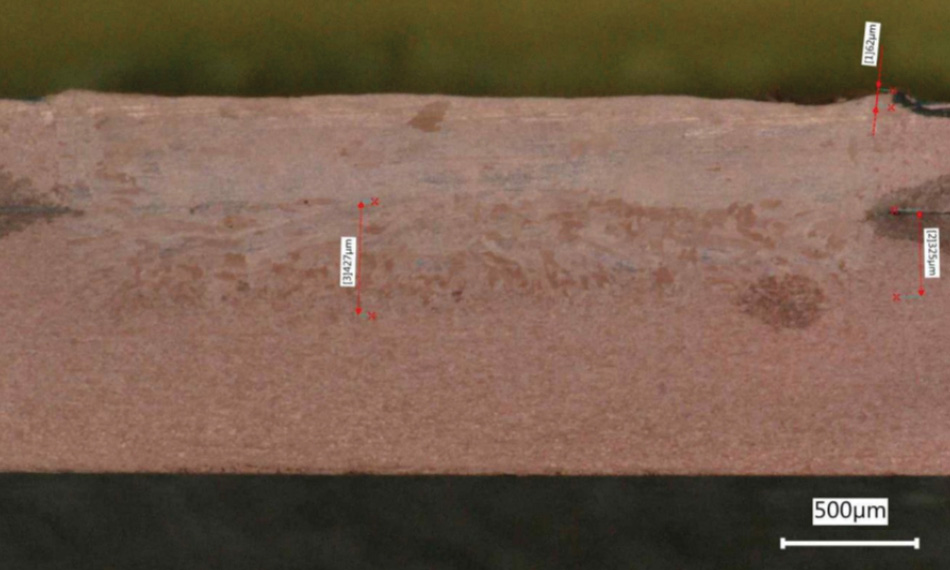

For example, one weld requires joining a 0.5 mm thick piece of zinc-coated copper to a 1.0 mm thickness of nickel-coated copper. The low melting point of zinc has presented problems for laser welding in the past. In particular, it bubbles chaotically when brought to the temperature necessary to melt copper. This results in voids and porosity in the finished weld seam, as well as a substantial amount of spatter.

This part required welds on both ends. One end was flat, and the other end had a 90° bend. These conditions were different enough that two separate sets of parameters had to be developed to optimize each weld. Plus, there is a plastic piece embedded in the part that must not be heated during welding.

The ability to adjust the exact shape of the weld using SmartWeld+ was very useful here. It allowed creation of a joint which was large enough to provide the required level of electrical connection and mechanical strength without straying too close to the plastic part. While similar weld paths are used on each side of the part, the directions they are applied in are different. The development teams in teamtechnik Poland and Coherent also found that for one of the welds, optimum weld results were obtained with a small gap between the parts.

For both welds, a key part of the solution was dynamic power modulation. This provides the ability to stabilize the melt pool during welding and eliminate porosity. It also substantially reduces spatter.

Handling process variability

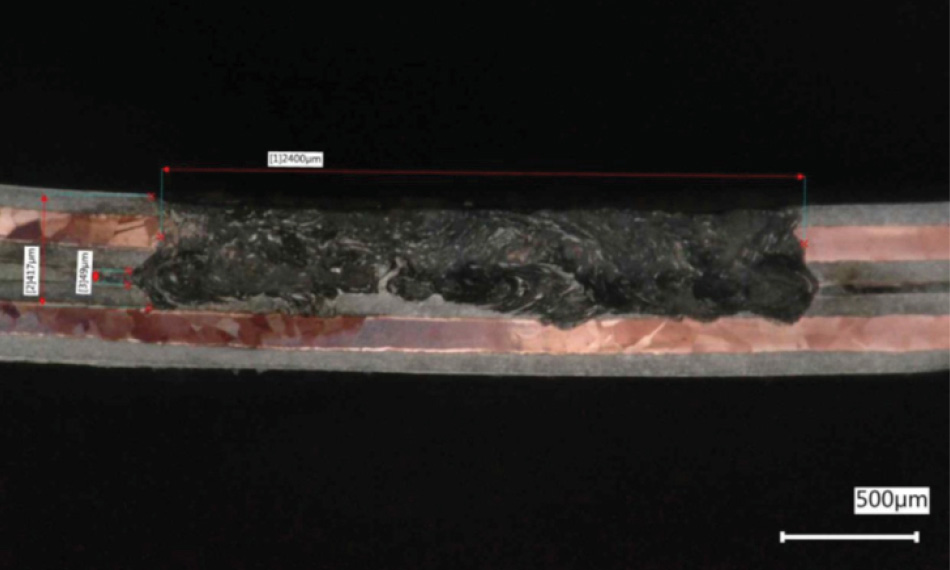

Another of the welds involved joining two 0.3 mm thick pieces of SIGMACLAD® together. SIGMACLAD is a composite material specifically designed for making electrical connections in Li-Ion batteries in packs. It’s a five-layer sandwich consisting of Ni|stainless steel|Cu|stainless steel|Ni. This combination delivers more desirable properties than any individual metal. Specifically, the copper provides excellent electrical and thermal conductivity (for heat dissipation), while the stainless steel layers make the material easier to weld and also increase weld joint strength. The outer nickel layers facilitate soldering and lend good corrosion resistance.

Because SIGMACLAD is specifically designed for compatibility with laser welding, neither the teamtechnik nor Coherent development teams expected that this join would represent much of a challenge. But, in practice, they found that material thickness variations, individual layer thickness variations, and low overall part dimensional tolerances created process deviations and inconsistent fit up. Testing determined that fixturing would be necessary to keep any gap between the two parts to less than 0.05 mm in order to achieve a 100% success rate for the welds.

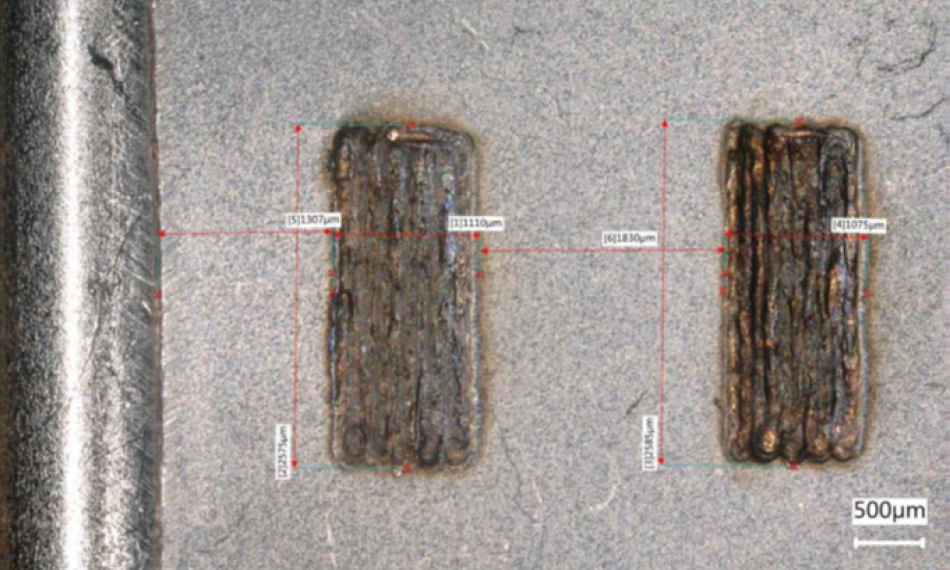

The overall weld in this case is 1 mm x 2.5 mm. The focused laser beam is much smaller than this, so the SmartWeld+ traces the beam back and forth several times while stepping slightly in the perpendicular direction between each scan to cover the entire area. Furthermore, testing showed that it was necessary to modulate the laser while moving, otherwise there was excessive spatter at the ends of the scan.

Some of the processes changed even after the equipment was installed and commissioned in the end user’s factory. The Coherent applications group continued to provide support to respond to this.

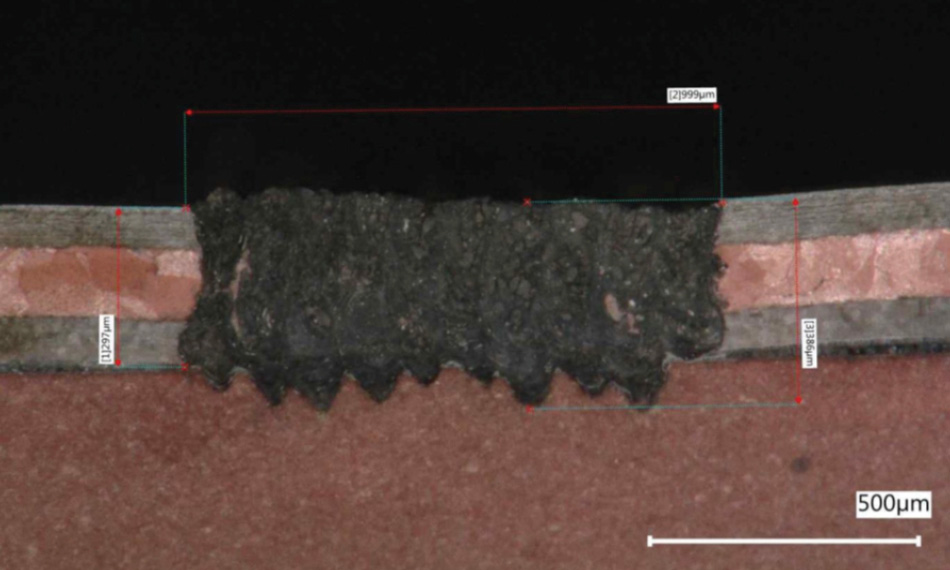

For example, in one weld 0.3 mm thick SIGMACLAD is joined to 1.0 mm thick nickel-coated copper. The problem here didn’t arise until after the equipment had been installed and operated successfully by the end user for two years. Then the materials supplier changed their formulation, and also introduced issues with the cleanliness of the copper. This resulted in a substantial amount of spatter using the process recipe which they had originally employed without difficulties.

The flexibility of the SmartWeld+ proved particularly valuable in this case. In particular, the ability to easily vary the weld parameters through software control without making any changes to the hardware of fixturing. A new cycle of testing at Coherent established that implementing laser power modulation in this process would solve the problem.

Partnering for success

Working with the Coherent development team allowed teamtechnik to concentrate on what they know best – namely automation. “We needed a partner to get all these laser welding processes developed within the time and cost constraints we had from our customer,” notes Maciej Zaborowski, Welding Technology Specialist, teamtechnik POLAND. “In particular we wanted to find someone who has the expertise and facilities to test the materials and determine if they could all be laser welded, and then develop specific process recipes that would work in production.”

“Coherent delivered on all these points. Plus, our cooperation with them didn’t end after this initial process development. They ’ve continued supporting us as changes in materials created production variances in processes that had been working well up to then. There was no other laser vendor we could find who would take on this level of process responsibility.”

“SmartWeld+ gives us great results and can readily adapt to make process changes. But the real reason we went with Coherent is their support. No other supplier was willing to do the development work necessary to ensure we could satisfy our end user’s requirements."

— Maciej Zaborowski, Welding Technology Specialist, teamtechnik POLAND

Figure 1. Cross section and top view of the 0.5 mm zinc-coated copper to 1.0 mm nickel-coated copper weld.

Figure 2. Cross section and top view of the 3mm SIGMACLAD to 3mm SIGMACLAD weld.

Figure 3. Cross section and top view of the 3mm SIGMACLAD to 1.0 mm nickel-coated copper welds.