Laser Machines and Systems

PowerLine

Laser-based system for marking and engraving a wide range of materials. Integrates a laser with focusing/scanning optics and software.

PowerLine laser markers are ideal for system builders and production line integration. Flexible software allows straightforward implementation of complex tasks such as 3D marking on curved surfaces, on-the-fly marking, engraving, and mark serialization.

PowerLine Laser Markers – Some Key Features

Choose from the most complete product portfolio, comprising 1064 nm, 532 nm and 355 nm wavelengths and USP lasers, as well as specialized beam delivery and scanning options.

Product Specifications

Model Name |

Laser Type |

Main Features |

Target Materials |

Typical Applications |

PowerLine C |

CO2 |

Economical, Versatile |

Most Non-Metals |

Engraving glass, organics, and natural materials. |

PowerLine E Series |

Solid State (IR, Green or UV) |

High-Quality Marks |

Diverse, Laser Dependent |

Semiconductor device marking, marking of organics by foaming, day & night, and grayscale marking. |

PowerLine E Twin |

Solid State (IR, Green or UV) |

High-Quality, Very High Speed |

Organics |

Serialization marking of semiconductor devices. |

PowerLine F Series |

Air-Cooled Fiber Laser (IR and Green) |

Unique Performance |

Metals, Plastics |

Engraving/marking of metals, marking of lead frames, ear tag marking, marking of organics by carbonization. |

PowerLine F Dual Head |

Air-cooled Fiber Laser IR |

High-Throughput, Cost-Effective |

Metals, Plastics |

Lead frames, IC strips, JEDEC trays, carbonization marks. |

PowerLine F Twin |

Air-Cooled Fiber Laser IR |

Very High Speed, Simultaneous Asynchronous |

Metals, Plastics |

IC strips, serialization marks, larger objects. |

PowerLine Prime |

Solid State IR |

Compact, Air-Cooled |

Plastics |

General marking in low or medium volume production. |

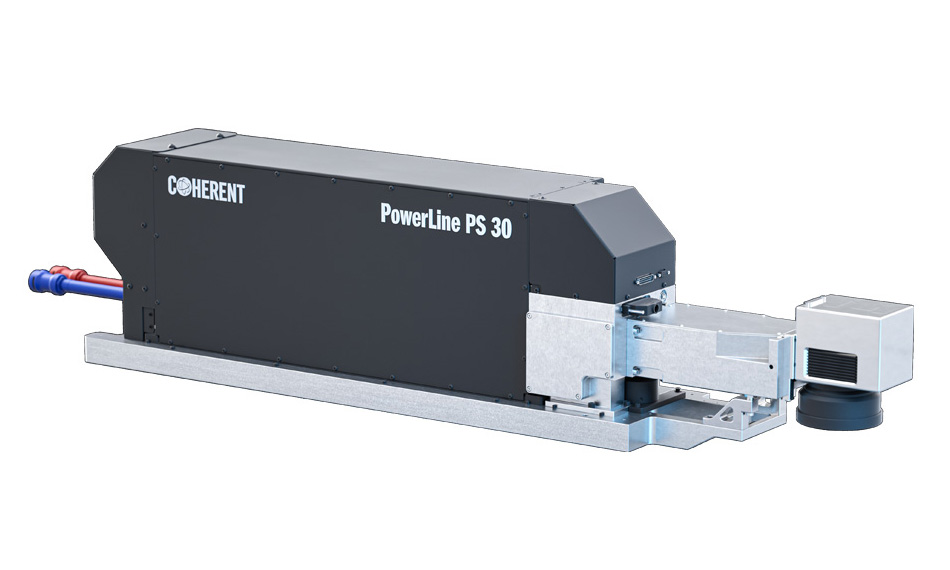

PowerLine PS 30 |

USP IR |

Laser Black Marking |

Steel, Titanium, Aluminum |

Laser black marking, micromachining. |

Featured Blog

Faster Picosecond Marking And Micromachining

With 28 W of output power, the new Coherent PowerLine PS 30 increases marking and micromachining throughput for medical devices, watch parts, glass, and tough materials. Its short pulse duration avoids the creation of a heat-affected zone (HAZ) in many materials. The Coherent Laser FrameWork software integrates all subsystem components into one software control and offers interfaces to machine factory systems.

Video Spotlight

Fast Shallow Marking with Precise Alignment

The latest PowerLine F QS green laser markers deliver a 3X increase in throughput for marking of semiconductor ICs and organic materials. The high-performance air-cooled fiber laser delivers up to 27 watts of green (532 nm) output. Combining it with PartVision, the Coherent machine vision, leads to fast and reliable marking. PartVision eliminates the need for specialized tooling, thus cutting costs. It can also compensate for the way parts have been placed in the working chamber; this speeds workflow and reduces errors.