Faster Picosecond Marking and Micromachining

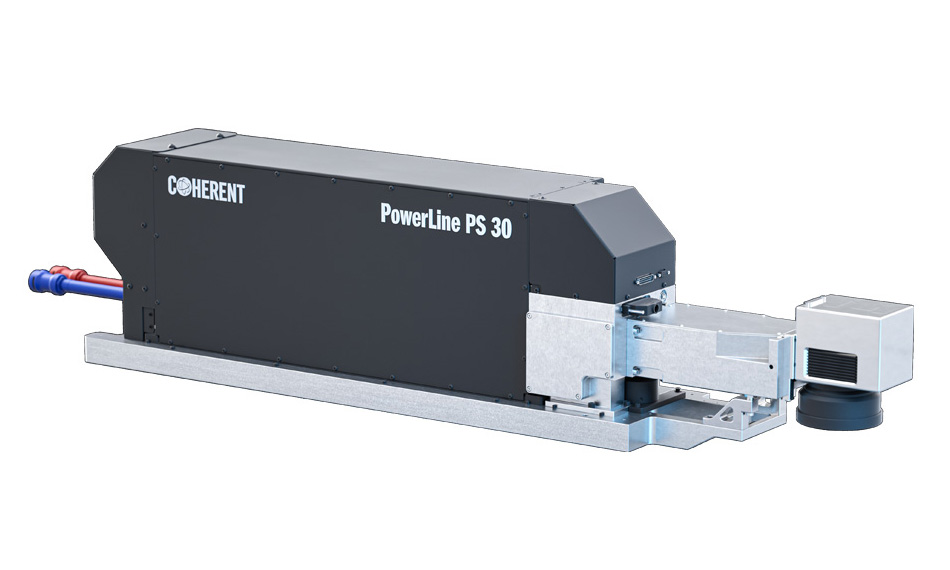

Mark medical devices, luxury watch parts, glass, and machine tools with the new Coherent PowerLine PS 30.

June 20, 2023 by Coherent

Delivering 28 W of output power, the Coherent PowerLine PS 30 significantly increases marking throughput for precision marking applications for medical devices, watch parts, glass, and tough materials like tungsten carbide. Our newest engineered subsystem includes control software, qualified components, and optional features such as integration of the Coherent PartVision packages for alignment and inspection tasks. Now, get the high-speed capability and quality of a picosecond laser with the throughput of a nanosecond laser.

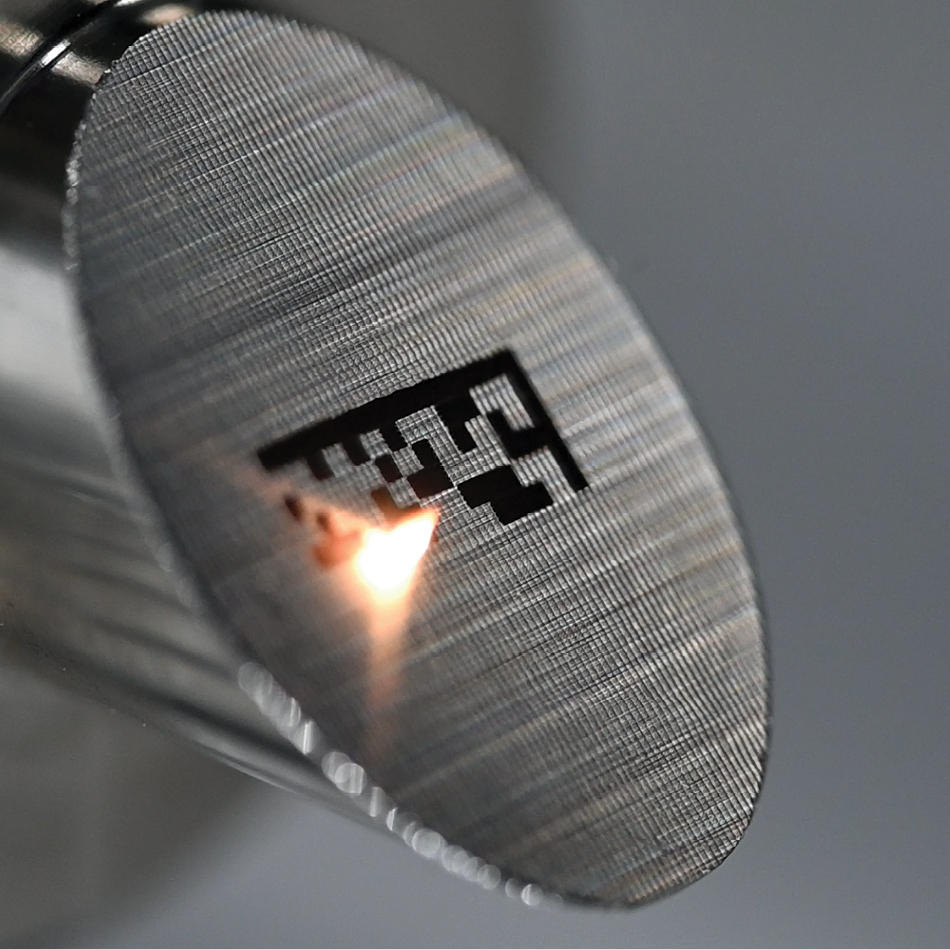

Precision micromachining at micron resolution

The process advantages for marking also extend to precision micromachining, with the flexibility of using up to 250 µJ pulse energy for cutting, drilling, or engraving. In particular, the short pulse duration avoids the creation of a heat-affected zone (HAZ) in many materials. Precision marks and micromachining features to a few microns of resolution are possible in both delicate and tough materials, with sharp edges and no microcracking, charring, or recast material. With no thermal debris the need for any potential downstream mechanical post-processing is reduced, therefore decreasing production cost.

High-quality laser black marking

Laser black marking is one of the most important processes that are uniquely enabled by ultrashort pulse lasers. The nanostructuring of the surface of stainless steel, titanium, and various other metals produces the highest-contrast black marks, eliminating viewing angle sensitivity. The method of nano surface modification — with almost no thermal input — creates marks that are passivation- and corrosion-resistant that will not fade even after many autoclave cycles.

The pulse duration of < 10 ps enables marking of materials with only limited absorption for IR nanosecond pulses, usually requiring a UV laser source. For instance, glass can be marked with the PowerLine PS 30, avoiding edge chipping and providing high controllability of marking depth. It also simplifies marking even the toughest machine tools made from hard materials like tungsten carbide, CBN (cubic boron nitride), and PCD (polycrystalline diamond).

A powerful software solution

The PowerLine PS 30 is equipped with a powerful and well-proven software package that supports a range of hardware options, which simplify the design and execution of even complex marking tasks:

New Coherent Laser FrameWork software integrating all subsystem components into one software control and interfacing to machine factory systems (Profinet, Profibus): Intuitive and easy to use, harmonized and standard interfaces, as well as connectivity. (Laser FrameWork also provides control in the ExactMark series, which are Class 1 complete systems featuring the PowerLine PS 30 subsystem.)

The PartVision option package enables completely automated operation including demanding vision tasks in conjunction with the Laser FrameWork software platform. This user-friendly object-driven software allows the operator to control workflow, parameters, visualization, automation, as well as other application details, all from one software platform.

Coherent subsystems are designed as ready-to-use solutions, which leads to a short time to market for your products and a reduction of non-recurring engineering costs. They are configurable with qualified and tested components, based on your requirements and with the support of our laser applications experts, lowering the overall integration challenge.

Learn more about the Coherent PowerLine PS 30.

Related Resources