CUSTOMER SUCCESS STORY

Lasers Enable Cost-Effective Day & Night Marking

The Challenge

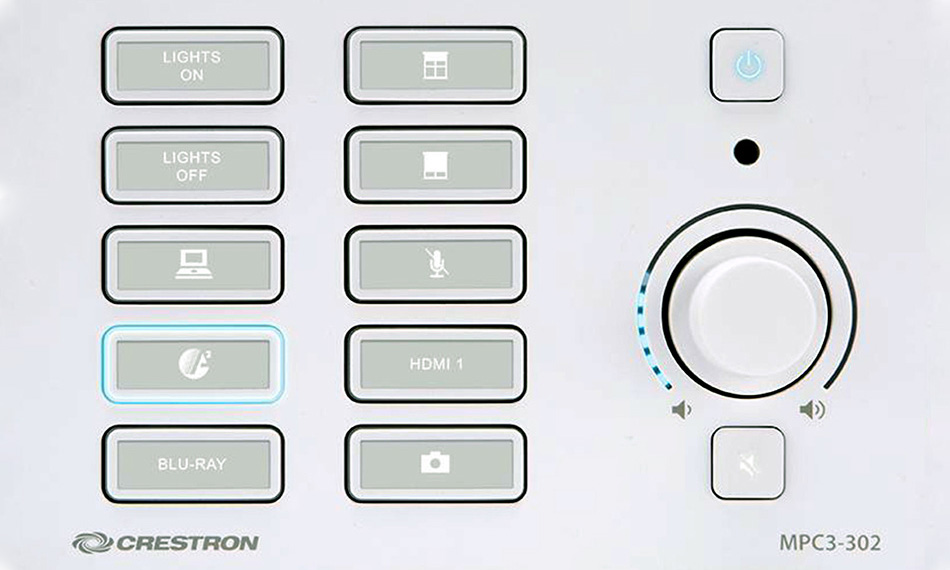

“Day & night marking” is used in automobiles, aviation, instrumentation and computer keyboards to make buttons and controls (like door locks, window controls, sound system adjustments) clearly visible under lighting conditions varying from bright sunlight (day) to low light (night).

Crestron Electronics, Inc. utilizes day and night marking to put characters and graphics on the remotes and keypads used with their custom automation and display equipment for commercial, educational and home environments. As their product has become more sophisticated, they needed a way to move from simple alphanumeric marking to making more complex marks, like graphics and logos. But, their small batch size – often just one or two units – meant they needed a marking system that was flexible, and which would allow custom marks to be rapidly created and produced. The combination of small batch sizes and high mark quality meant that traditional day and night marking methods, like two-part injection molding or rotary engraving, weren’t applicable or cost-effective.

The Solution

Crestron Electronics now uses the Coherent LME, a Nd:YVO4 laser-based marking system, for day & night marking. This system delivers higher speed and the ability to reproduce complex graphics, which can’t be accomplished with rotary engraving with a steel cutting tool. The Coherent LME system software also provides Crestron Electronics with essential capabilities they need to service their own customers. Specifically, it enables their customers to easily define marks using a supplied application, and then upload the designs to Crestron Electronics, where the parts themselves are manufactured.

The Result

Utilizing the Coherent LME, Crestron Electronics can now readily produce virtually any type of mark, whether alphanumeric or graphical (a logo or icon) with precision and high legibility. The Coherent Visual Laser Marker (VLM) software even enables Crestron Electronics dealers to bring up a keypad layout on their computer screen, define whatever symbols or nomenclature their customer requests, and then simply e-mail all that in to the production plant. Crestron Electronics can then produce that mark on the part, and the VLM software handles all the background tasks necessary to perform that with almost no operator intervention. The increased speed of the LME over mechanical methods delivered Crestron Electronics a rapid return on their capital investment.

“Mark quality is our single biggest priority. The Coherent system delivers that, plus an increase in production speed, and even simplifies the process of marking customer supplied graphics."

—Keith James, Director, Strategic Supply Chain and Manufacturing Operations, Crestron Electronics

Figure 1: Coherent LME produces complex graphics, which can’t be accomplished with rotary engraving with a steel cutting tool.