Fuel Cell Manufacturing

Increase cell efficiency by employing advanced bipolar plate geometries, enabled with ARM fiber laser welding.

- High Speed Weld bipolar plates at high throughput speeds without sacrificing quality.

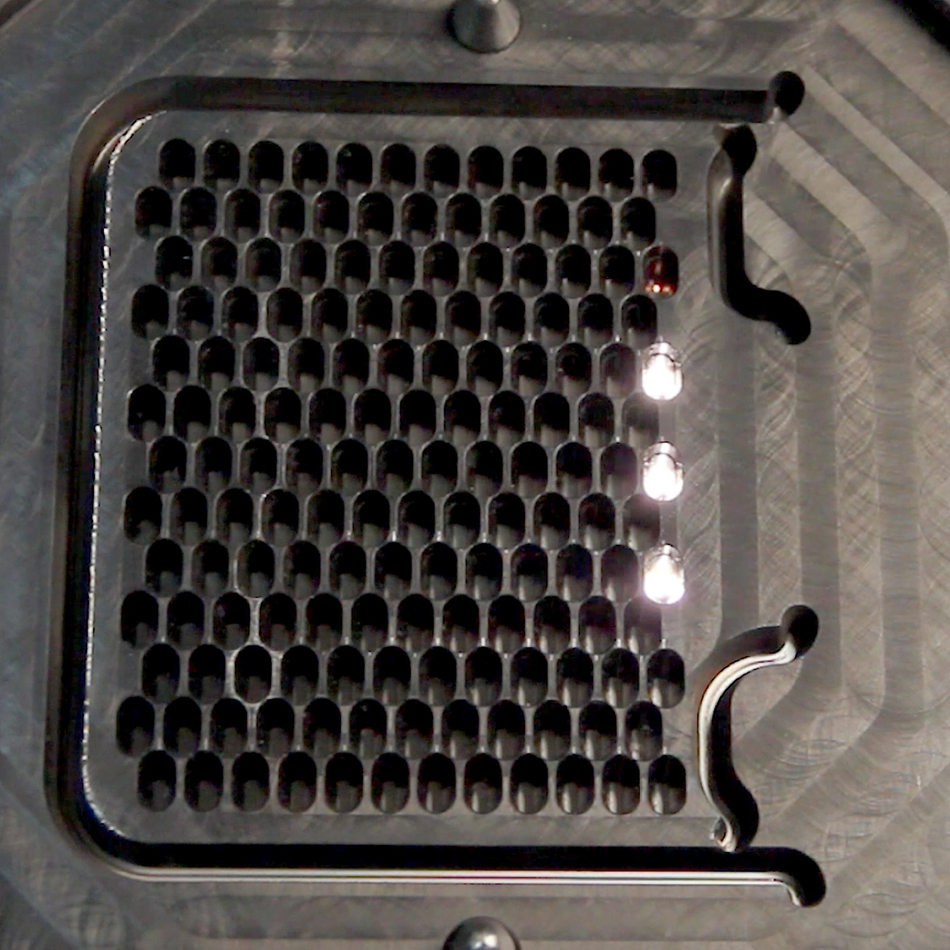

- Dense Welds Improve weld density with the fine control possible through ARM technology.

- Increased Conductivity Get higher conductivity welds for improved battery performance.

Production Welding

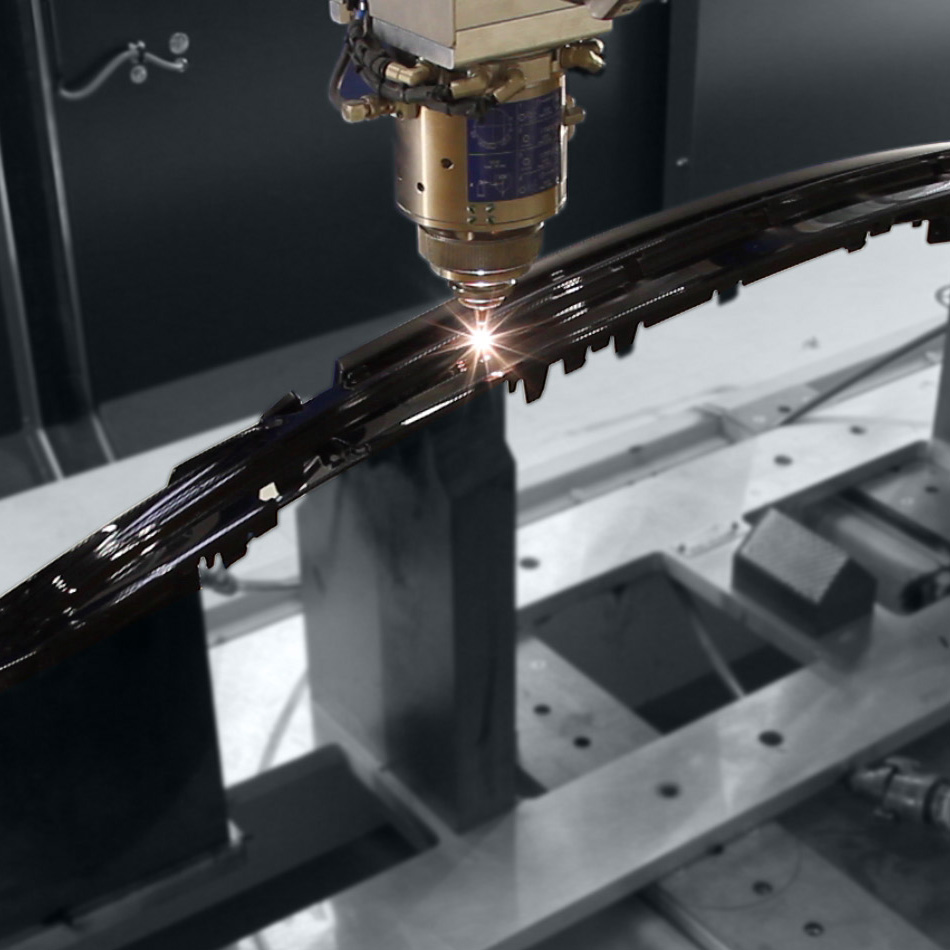

Welding membrane electrode assemblies (MEAs) between bipolar plates is a key step in fuel cell production. Because of the large number of MEAs used in each fuel, this welding must be performed at high speed to make the assembly process economically viable. But traditional fiber lasers haven't delivered the necessary weld quality, and tend to produce “humping” in the weld seams. Coherent HighLight FL-ARM lasers solve this problem and enable cost-effective bipolar plate welding.

Let's get started

Please submit some information about yourself, and a product expert will contact you within 2 business days.

Product Applications

More Featured Assets

Fuel Cell Products

Video Spotlight

50 % Speed Increase: High-Speed Laser Welding of Bi-polar Plates

The HighLight ARM Fiber Laser dramatically speeds up fuel cell production by enabling high-speed laser welding of bi-polar plates without the problem of “humping” experienced with traditional fiber lasers. It is achieved by employing a unique adjustable ring mode beam.

Success Story

Bröking-Plastex: CO₂ Laser Enables Automotive Mass Customization

Find out how Bröking-Plastex uses Coherent CO₂ Lasers to increase cost-effective production and mass customization of automotive parts.

Ready to Get Started?

Share your contact info and a specialist will reach out.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.