The Surging Interest in MDM Cutting with Femtosecond Lasers Explained

A combination of improved performance/cost for these lasers and a growing demand for their superior cutting quality in smaller medical devices is driving strong uptake.

October 18, 2022 by Coherent

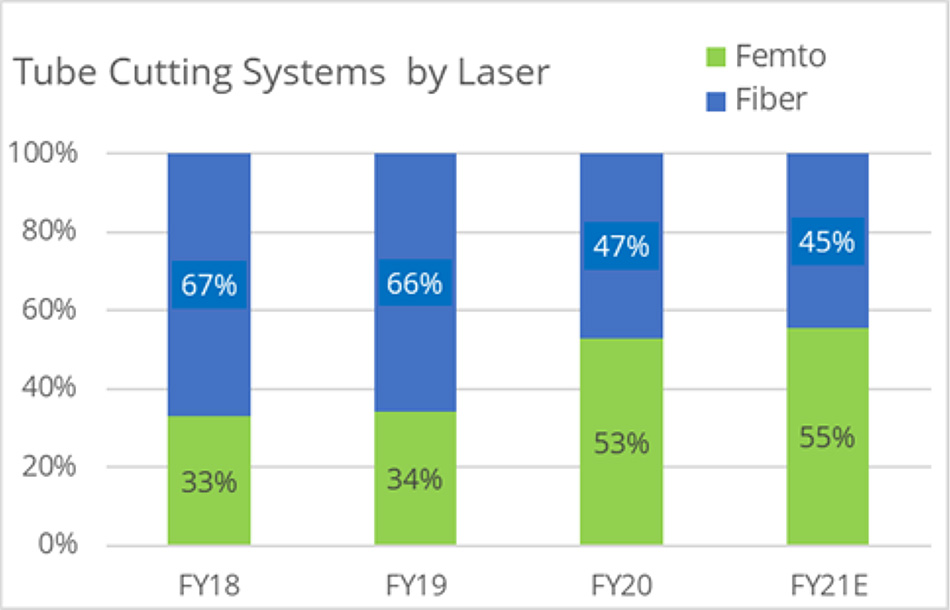

Relative system revenue for Coherent tube cutting machines based on fiber lasers and femtosecond lasers.

Fiber lasers have dominated cutting and drilling applications in the medical device manufacturing industry for quite a few years because of their relatively low cost, scalable power, and high reliability. Femtosecond lasers offer a clear advantage in terms of cut quality, but for a long time, they only secured a small share of the market. But this is suddenly changing quite fast as evidenced in the sales figures for Coherent tube cutting systems, as summarized in the figure. Let’s take a look at what is driving this dramatic growth in market share, compared to fiber lasers.

Femtosecond lasers – Better, finer cuts

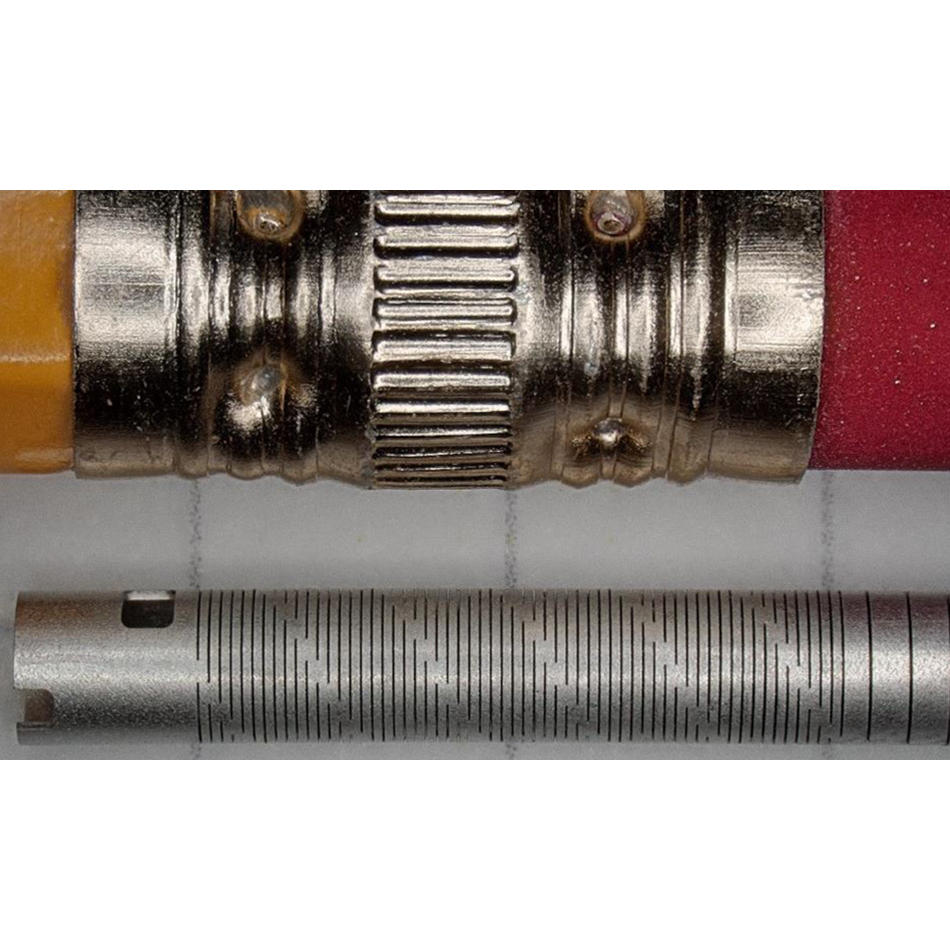

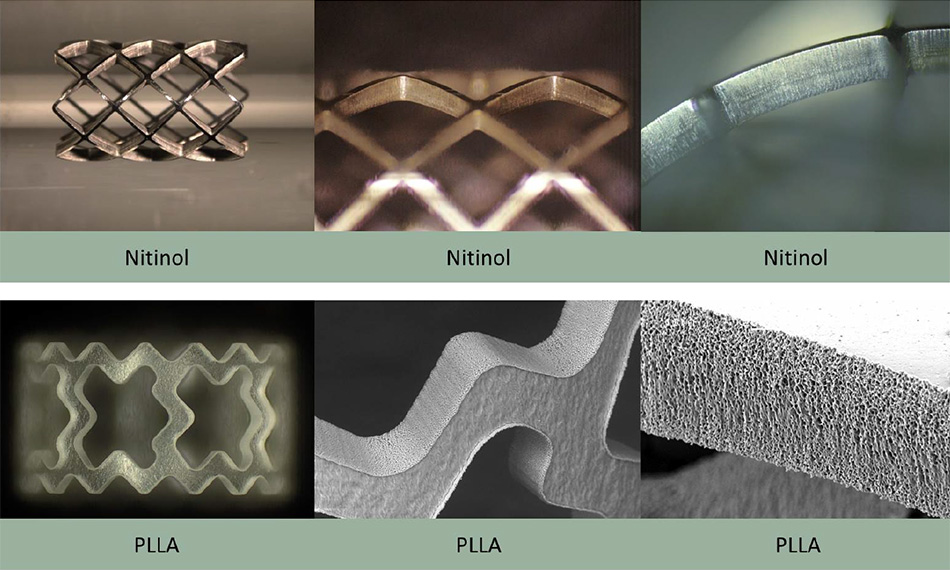

The unique combination of advantages using femtosecond (fs) lasers for materials processing have long been known. With traditional lasers like fiber, most of the material interaction is photothermal, resulting in a heat-affected zone (HAZ). In precision applications, this limits the minimum size of features that can be cleanly machined without melting, it can cause unacceptable functional or cosmetic damage, and often requires mechanical post-processing (e.g., deburring, manual polishing, or reaming). In contrast, the fs laser delivers orders of magnitude shorter pulses with much higher peak power that instantly vaporize material before heat conducts into the part. This colder more precise cutting enables the creation of smaller features with no recast debris, so no grinding or polishing is required. Plus the method works on just about any material, including mixed material parts such as polymer/metal layers – see figure.

Femtosecond lasers can cut virtually any materials with great edge quality and no recast material.

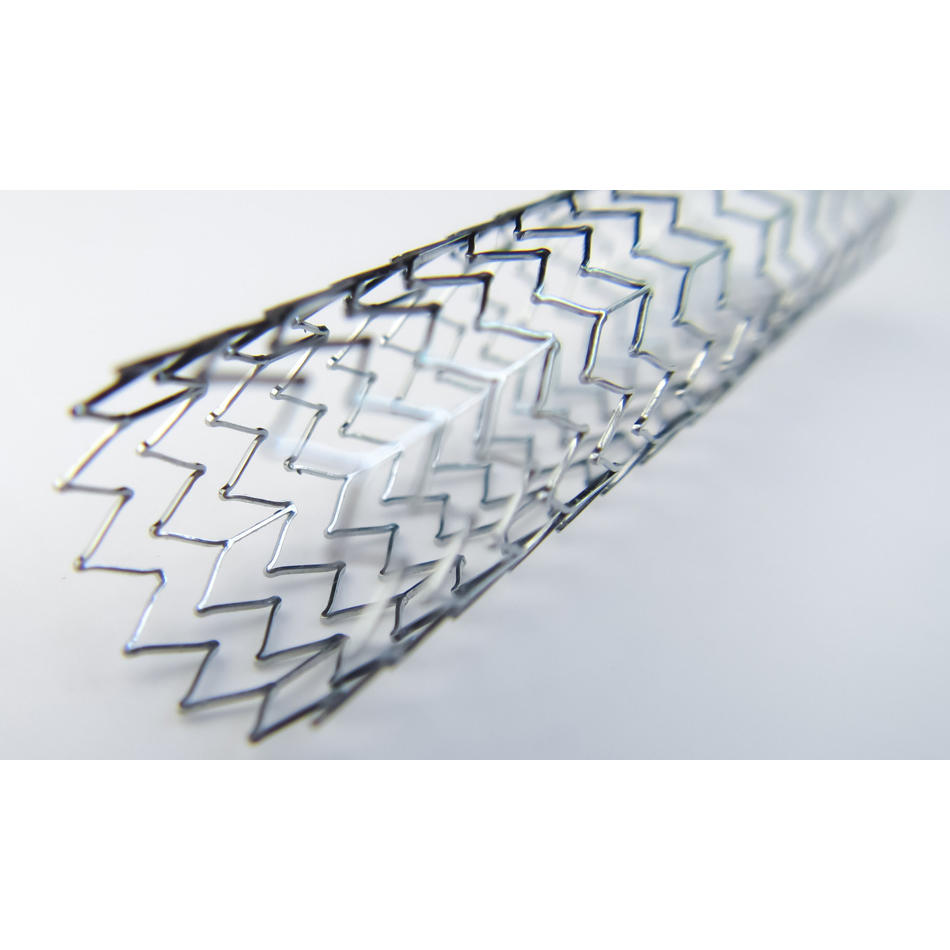

Miniaturized devices with finer details (e.g., struts)

The big driver causing the recent increased uptake in fs laser processing is the demand for medical devices (e.g., peripheral stents, hypo tubes, minimally invasive tools, etc.) characterized by smaller, thinner-wall components with increased number of cut details. We see this is particularly the case in demand for machines configured for tube cutting geometries as in the figure above. In addition, the use of more challenging materials and more expensive materials is also a secondary driver. An example is magnesium bioabsorbable stents where post-processing after fiber lasers can lower yields to 50% but fs laser cutting needs no post-processing. Other industries (e.g., displays/electronics) are moving towards this technology too which provides additional market demand further incentivizing laser manufacturers to develop advanced fs lasers and machines.

Advances in fs lasers - Higher power, lower cost-per-watt

Indeed, femtosecond lasers have reached a new level of maturity in terms of performance, economy, and reliability. Power is a particularly important performance parameter since it directly determines throughput. An example of next-generation fs lasers is the Coherent Monaco series where the maximum power has been successively increased from less than 20 W to over 60 W during the time span covered by the sales chart. The cost per watt for most femtosecond lasers has also recently dropped. So these lasers can deliver higher throughput together with lower cost per part. Early Monaco models have been operating in 24/7 demanding production environments for a few years, underlining the increased reliability of fs lasers that further contributes to the lower overall cost of ownership. Together with the cost savings from eliminating mechanical post-processing steps, this has definitely resulted in an economic tipping point for several precision cutting tasks.

Streamlined, automated machines

Of course, most people making medical devices don’t want a laser, rather they want a complete laser machine. And the last part of the picture is the availability of advanced fs laser machines with streamlined automated part handling and inspection. These also include easy-to-use software that doesn’t require extensive training or expertise. This provides the user with the flexibility to quickly switch between small batches of different devices or to perform long unattended runs of higher volume components. An example is the ExactCut series from Coherent that incorporates our newest operating software: Coherent Laser FrameWork.

Bottom line: Fiber, fs laser, or both?

One of the biggest questions for anyone in MDM acquiring a new machine today is the choice between fs or fiber laser. The main remaining advantage for the fiber laser is the ability to cut faster and to cut thicker parts because of its higher available power. However, for thinner parts, the power and speed advantages are often reduced because of the need to lower the repetition rate and avoid cumulative thermal damage. So the bottom line is that the optimum laser type really depends on the application specifics.

This is a reason why the latest laser machines for cutting medical devices are now available with a choice of fs or fiber laser, or as a hybrid option with both lasers. With this latter option, users can seamlessly switch between lasers, even in a single job where there may be cuts that can be made more economically with a fiber vs a fs laser, and vice versa.

Read more about how the Coherent StarCut Tube Hybrid helped Motion Dynamics leverage laser cutting for neurological sub-assemblies.

Related Resources