Speeding Laser Marking

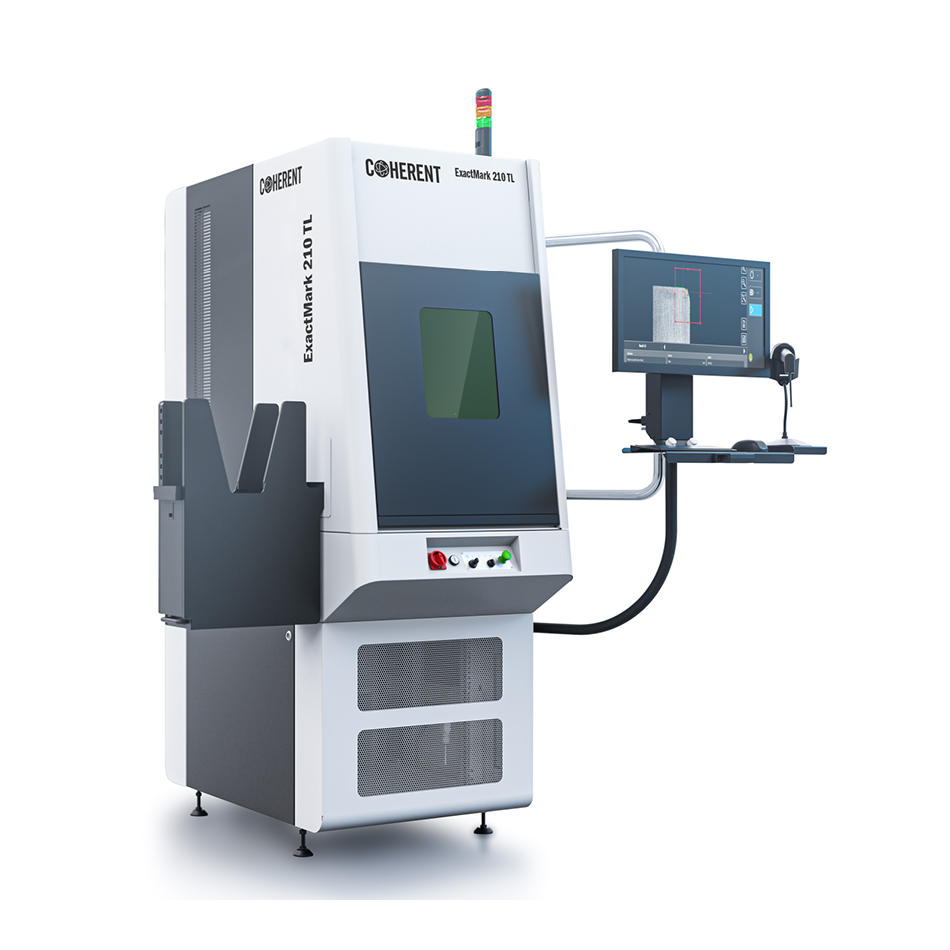

Coherent ExactMark 210 TL — with 6-axis robotic part handling — fully automates multi-sided laser marking of trays of small parts.

January 26, 2023 by Coherent

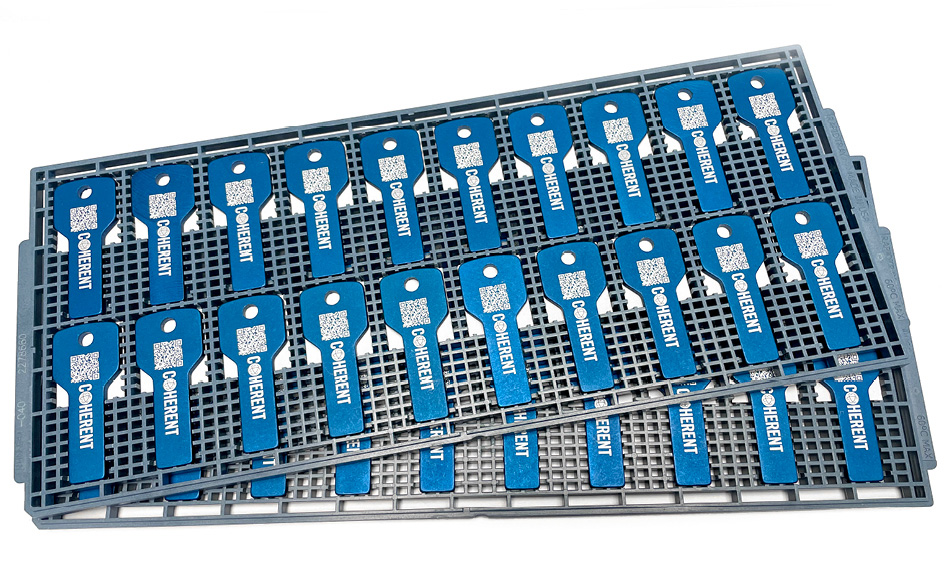

Many medical devices, disposables, and other volume components require permanent marking on more than one side. However, the unit value of these parts is often low, which means that they cannot support the time and cost of individual manual laser marking. And this mass marking task is even more challenging where the parts are not simple shapes with flat sides.

The latest Coherent ExactMark 210 TL is designed to provide an economical, practical solution to this common problem by integrating a robot arm option within the processing cell — ideal for applications in medical devices and disposables, electronic components, machine tools, and other industries.

The option of a 6-axis robotic handling system delivers key benefits including lower labor costs and batch processing times, particularly for multi-sided marking of trays of parts:

- Multi-sided marking – robot-assisted marking on multi-face objects

- Hands-free operation – parts handling, PartVision alignment, and mark verification

- Long MTBA – up to 30 trays of components in a single run

- Simple and intuitive operation – user-friendly Laser FrameWork software

The ExactMark 210 TL allows multi-sided marking of up to 30 trays without operator intervention.

The combination of tray loading – up to 30 trays in a single run – and multi-axis robotic handling shortens the cycle and supports long Mean Time Between Assistance (MTBA), minimizing operator intervention and labor costs. This is particularly advantageous for multi-sided marking applications in asymmetric parts such as medical devices. All markings can be made using a machine vision function called PartVision for automated and precise mark placement. PartVision can also check and verify the mark quality.

The operation of the ExactMark 210 TL is integrated under the intuitive Coherent Laser FrameWork software suite, which simplifies the creation and execution of any marking task through simple drag-and-drop functionalization. The user places the marking, inspection, and automation steps on to a job timeline using simple drag-and-drop operations. This software also supports different user access levels, allowing production personnel to operate equipment without changing job parameters.

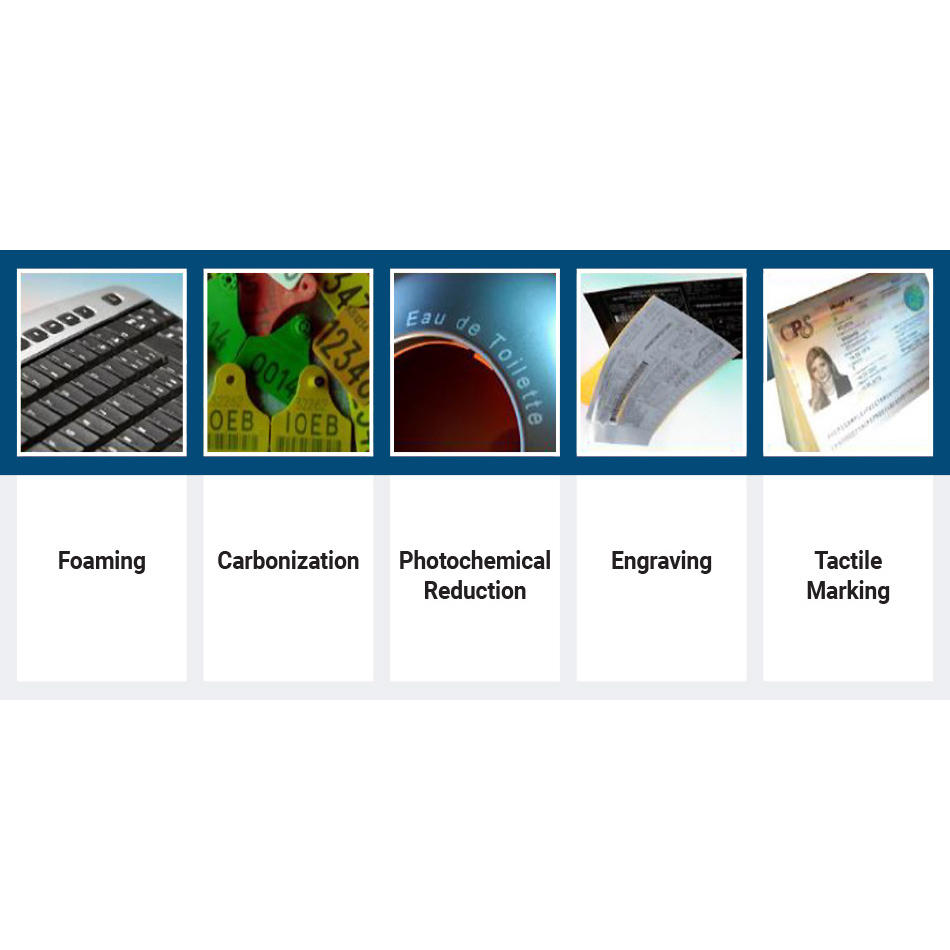

The ExactMark 210 TL is available with a full range of infrared lasers with outputs from 6-95 watts, enabling cost-effective marking on both plastics and metals. It is also offered with the Varia laser, enabling the laser pulsing characteristics to be precisely configured to suit different marking jobs. Plus, this new marker can accommodate parts with heights up to 40 mm, supporting both magazine and stack-type JEDEC trays.

Related Resources

Contact us for a full productivity calculation

See how much you can save on cycle time and labor costs.