Coherent Labs: Laser Expertise for Manufacturers Around the World

The best way to get robust, reliable laser processing into your production line.

April 27, 2022 by Coherent

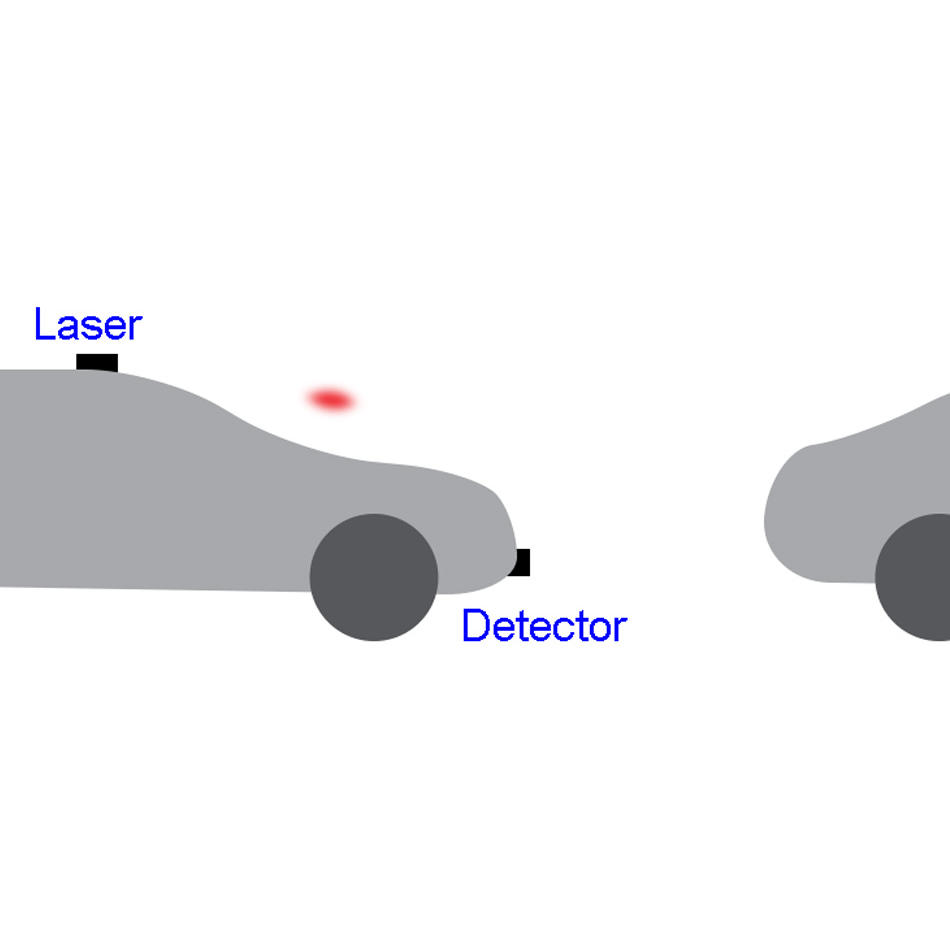

Manufacturers in industries as diverse as microelectronics, medical devices, automotive, aerospace, and more, all strive towards the same overall goal – to improve product quality, features and reliability without increasing cost. Lasers have proven an invaluable production tool in this endeavor. That’s because they offer unique capabilities to weld, cut, structure, and mark just about any material with precision, speed, and unmatched quality.

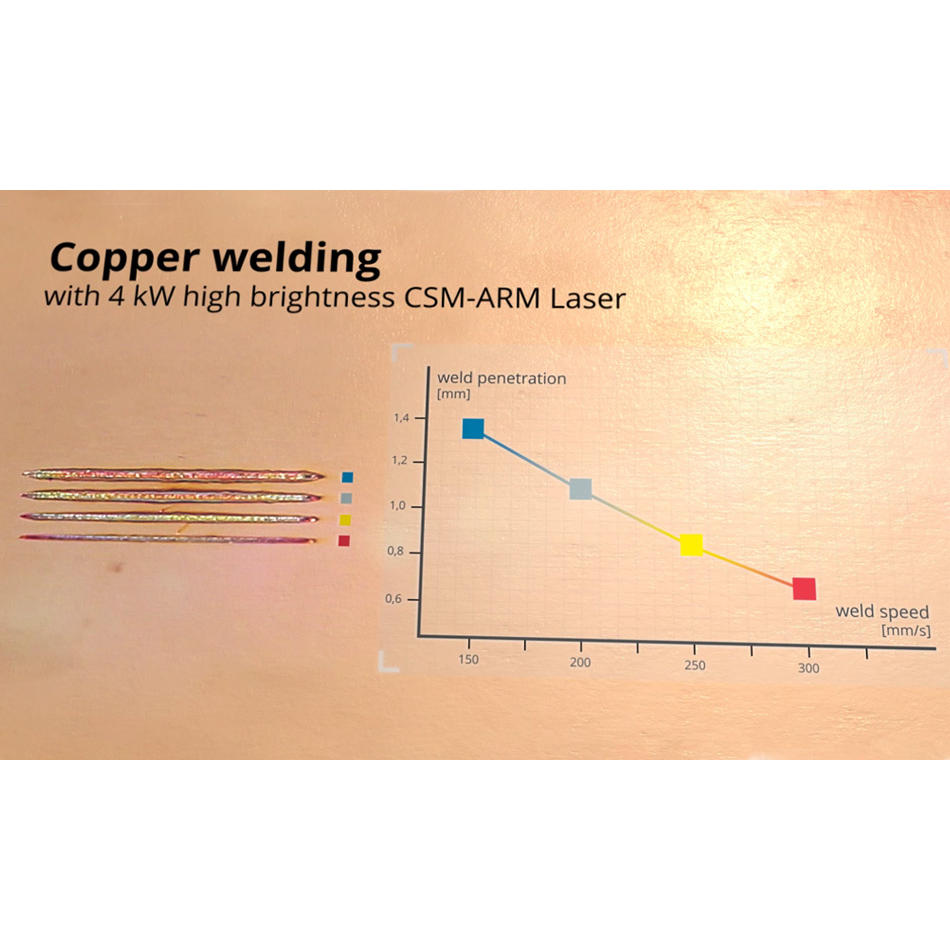

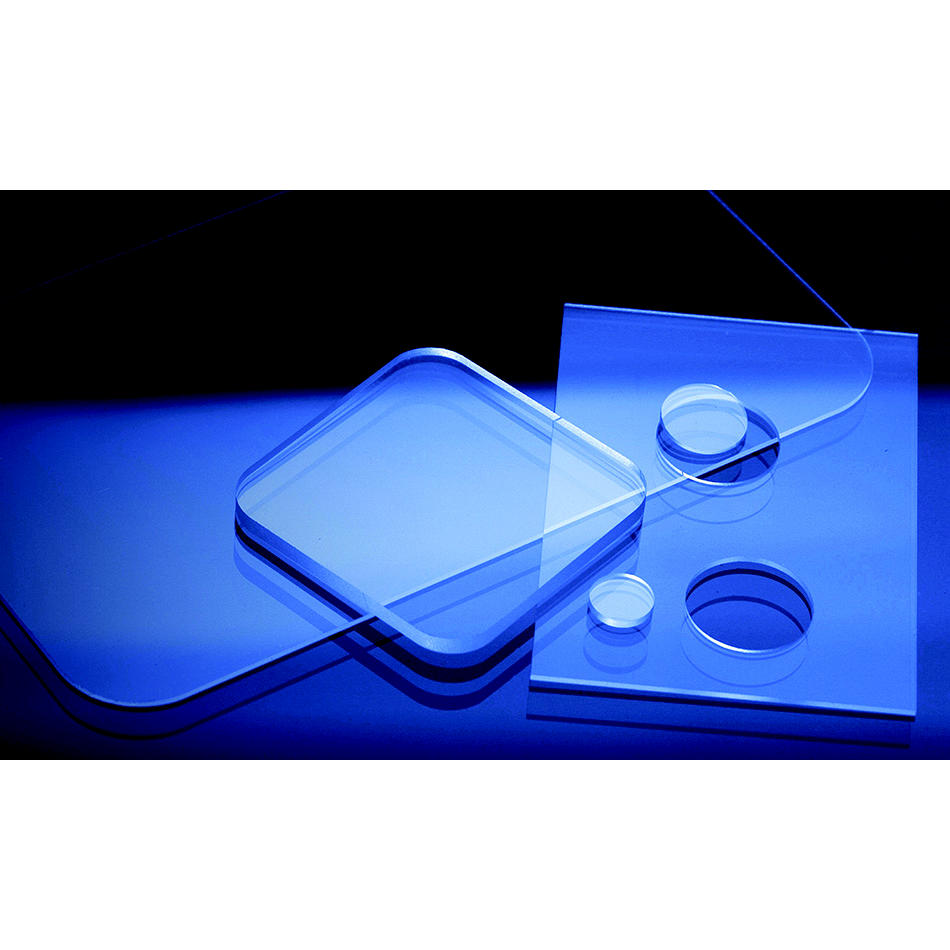

But there are many different kinds of lasers in use in this huge spectrum of industrial materials processing applications. These range from multi-kW fiber infrared lasers for welding auto bodies down to ultraviolet, ultrashort pulse (USP) lasers for precision glass cutting. Plus, each of these lasers operate over a “process space.” That is, a particular range of output parameters they can deliver (power, repetition rate, peak pulse energy, focused spot size, and more).

So, how does someone looking to implement a new laser process decide which source to use? And, then, how do they determine the best configuration for the laser system, and the exact process parameters that will deliver the optimum results?

Coherent Labs delivers laser expertise

You really have to be a laser expert to figure all this out. This is truer now than ever before because really getting it right in the most demanding new applications requires finesse, not brute force. This means understanding every nuance of the laser/material interaction in order to get precisely the desired results – in terms of the process, the speed at which it’s performed, and the cost.

And, guess what? That’s exactly what Coherent Labs does for you. Our laser experts are at your service. We’ll analyze your problem and develop the optimum solution based on our extensive applications experience and know-how. Plus, since Coherent makes just about every conceivable laser type, we’ll select the ideal source for your application – not just the one particular type we happen to make.

How can we make this bold claim? Our experts engage customers on over 2,500 projects every year. Coherent Labs is actually 19 individual facilities, spread over North America, Europe, and throughout Asia. These are staffed by 75 engineers who possess well over a century of combined experience in laser materials processing.

While many of these centers tend to focus on technology of specific interest for that particular location (such as automotive production in Plymouth, Michigan, or microelectronics fabrication in Shenzhen, China), each is a well-equipped and fully staffed operation. Typically, a Coherent Lab group has:

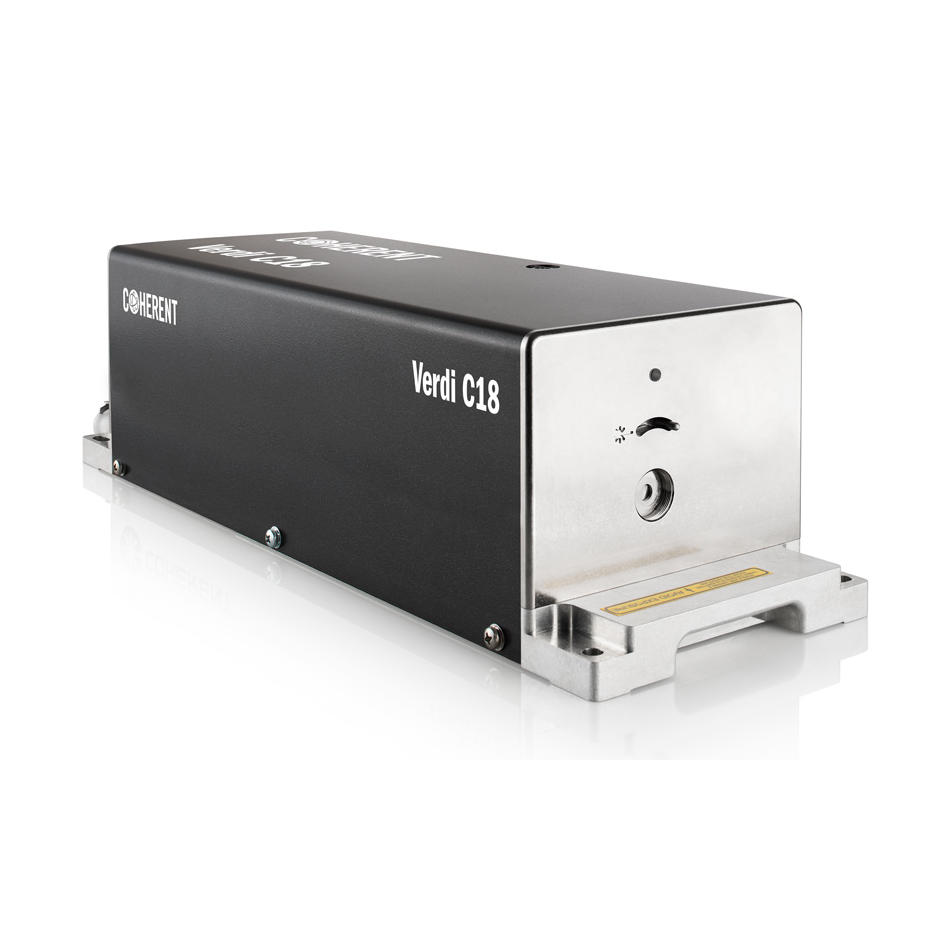

- A range of laser sources and laser-based systems, often including our unique HighLight Adjustable Ring Mode fiber laser (FL-ARM), excimer lasers, Monaco or HyperRapid USP lasers, solid-state nanosecond lasers, high power diode lasers, and CO₂ lasers.

- Gantry or robot arm-mounted lasers, 3D remote welding heads, and scanning systems for automated part processing.

- Process monitoring equipment, like vision systems and high-speed cameras.

- Metrology and analysis instrumentation, including SEMs, optical microscopes, and hardness and tensile strength testing gear.

- Meeting rooms and video conferencing equipment to facilitate customer communication.

Coherent delivers laser-based solutions

How do you put the expertise and capabilities of Coherent Labs to work for you? It usually starts by supplying us with some material samples along with specifications for your desired results. In particular, telling us the process you want performed (welding, cutting, marketing, etc.), the specific results that define “success,” and your cost and throughput targets.

We’ll do testing to establish if the process can be performed, and how it can be done best. If all you need is a laser, it could end there. Or, we can develop a laser system that integrates into your existing production line (typically a laser source and process head), all the way through to a complete, self-contained laser machine. And, most importantly, we’ll help determine the ideal process recipe at Coherent Labs, or by doing a pilot production test in your plant.

The commitment from Coherent Labs doesn’t end after your testing is over or your system is delivered, though. We provide ongoing after-sales support to keep you running, and to help you adjust your process as your needs change or evolve.

There are so many incredibly complex and sophisticated products now being manufactured. OLED displays, wearables, miniaturized medical devices, batteries for e-mobility, and more. Lasers perform critical enabling processes in the production of many of these because they work faster, cleaner, and more precisely than any other fabrication technology. The expertise and facilities offered by Coherent Labs removes the barrier to you accessing these benefits and is the shortest path to bringing cost-effective laser processing into your own production.

Contact Coherent Labs today for a no-cost consultation.