Laser Marking and Engraving Machines

Choose an economical laser marker, a self-contained table-top system, or a fully-automated system with robotic parts handling.

- Complete Laser Portfolio Get a marker with the laser that perfectly matches your application.

- Marking Experience Work with the company that fully understands your application.

- Maintain Maximum Throughput Get fast local service from our global team of experienced professionals.

Complete Range of Laser Marking and Engraving Systems

Choose a laser marker, a fully-featured automated system, or anything in between. Get the performance you want and only the features you need with a solution that matches your application and your budget.

ExactMark Laser Marking Systems

ExactMark laser marking systems include a motorized z-axis for automatic focusing as well as a range of optional motion axes and laser types.

- IR, Green, or UV laser - Mark any material.

- USP Laser Option - Corrosion-resistant laser black marking of metals.

- Large Marking Field - Ideal for trays, e.g., JEDEC.

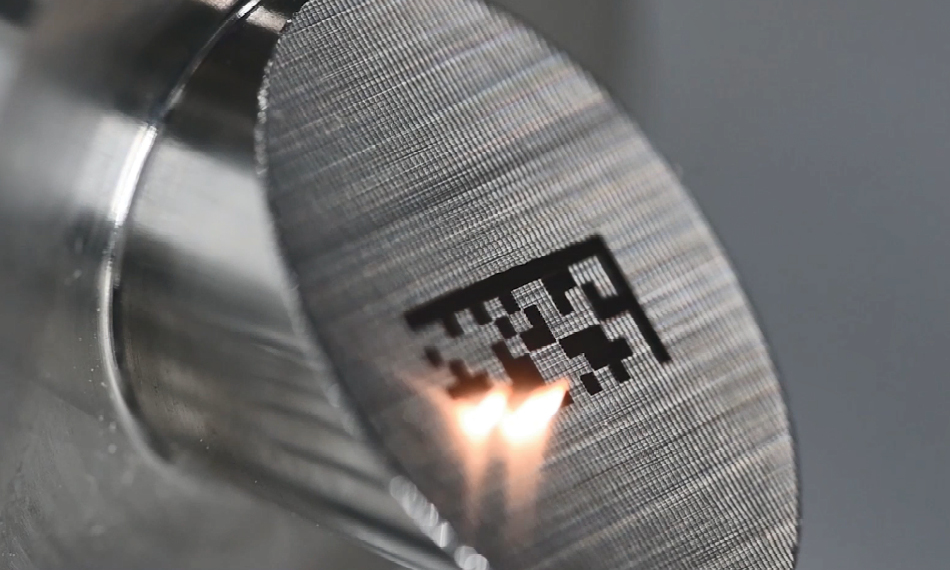

PowerLine

PowerLine Series lasers are ideal for system builders and production line integration for 3D marking, on-the-fly marking, engraving, and mark serialization.

- Simplify Complex Tasks - Flexible software for 3D marking and more.

- Eliminate Risk - Thousands of these proven markers are in the field.

- Wide Choice - The best laser for your needs.

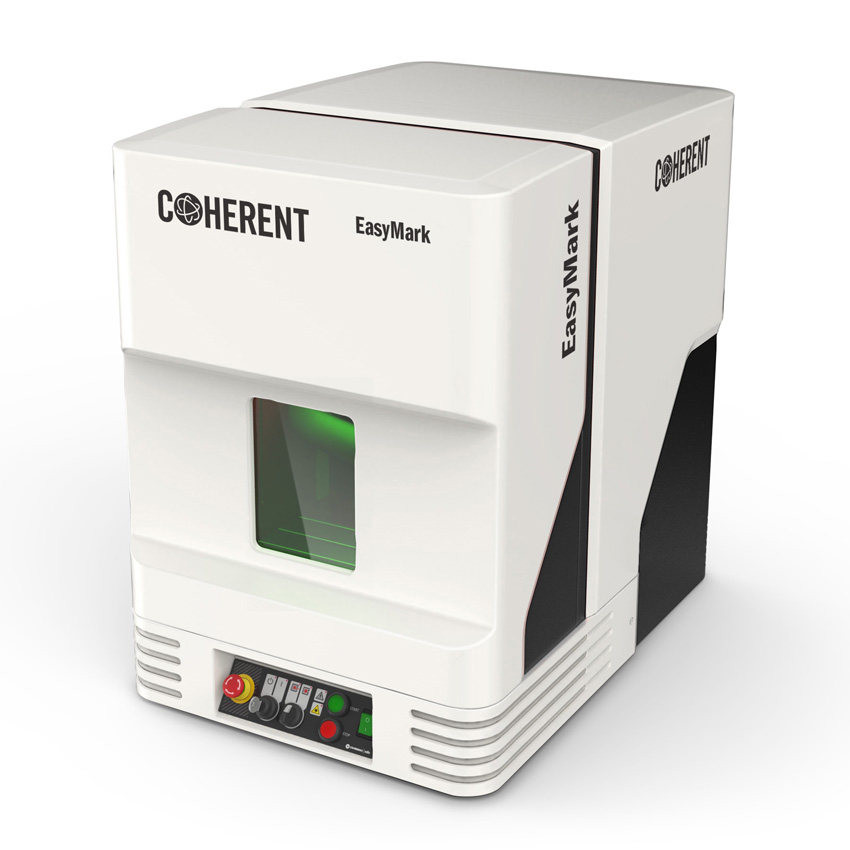

EasyMark Series

EasyMark Series are self-contained, table-top laser marking systems for a wide variety of marking, annealing, and cutting tasks in many materials.

- Economical and Reliable - Rugged fiber laser technology.

- Simplify Complex Marks - Easy to use Visual Laser Marker (VLM) software.

- Accurate Mark Placement - Optional integrated camera.

AP 530

Fully automated laser system for marking and surface texturing of medical devices in both tubular and free-form shapes.

- Multi-axis robotic part loading/handling

- Marking, creating deterministic textures

- Multiple laser options for diverse tasks

CombiLine Series

CombiLine laser marking systems deliver precision and operational simplicity to match a wide range of complex laser marking applications and machine setups.

- Extremely Versatile - Several laser options and multi-axis motion choices.

- High Throughput - Optional continuous operation.

- Optional Robotic Loading - Automated side loading/unloading of parts.

LabelMarker Advanced

LabelMarker Advanced provides high-speed marking and kiss cutting for common laser label materials, including simplified foil processing and singulation.

- Completely Versatile - Supports all common laser label materials and foils.

- Simplified Operation - Object-oriented VLM (Visual Laser Marker) design software.

- Optimized Performance - multiple laser choices and label handling options.

Featured Blog

Lasers Enable Cost-Effective Day & Night Marking

Learn how lasers mark buttons for cars, laptops, and other electronics that can be seen in both daylight and the dark.

Ready to Get Started?

Share your contact info and a specialist will reach out.