CUSTOMER SUCCESS STORY

Laser Machining Delivers Superior Parts for Swiss Watches

The Challenge

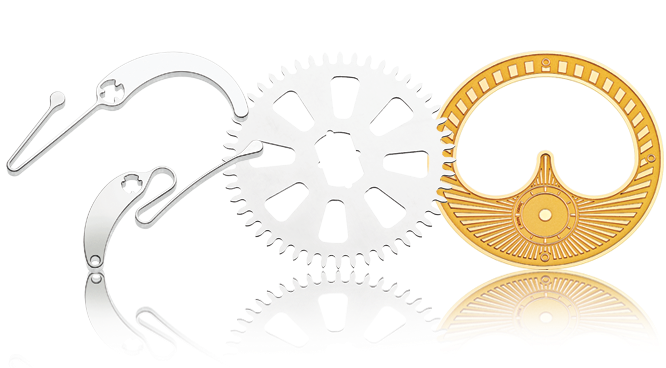

Swiss watchmaking has long been synonymous with precision, excellence, reliability, and high value. TechnoCut, located in Bonfol, Switzerland, was founded in 2005 with the aim of using laser technology for contract manufacturing of small parts for the country’s iconic industry, primarily involving laser cutting and engraving. Julien Montavon is the Technical Director and a co-founder of TechnoCut. He explains, “We believed that there was a tremendous opportunity to bring the benefits of laser machining to the watch-making business. Small parts were still produced primarily by stamping or even manual cutting/engraving, with occasional use of techniques like electrical discharge machining (EDM). ” A challenge was that Technocut wanted machines with a very specific set of features. But in their startup phase, they simply could not afford the luxury of machines loaded with additional features that they would never need.

The Solution

After careful evaluation, they selected a Coherent MPS machine. Montavon states, “We were able to optimize everything about the machine, from the type of laser – we chose a femtosecond laser – to the number and type (translation, rotary) of motion axes, even the size of the cutting box and the overall footprint. When we started with Coherent, it really was like getting a completely custom, made-to-order machine, but without the high cost.” He adds that they chose the femtosecond laser for its versatility; the watch industry uses an incredibly wide range of materials. Internal parts are fabricated from brass, copper alloy, and steel. But the face and hands can incorporate all kinds of metals and “exotic” non-metals to increase their aesthetic appeal and perceived brand value and exclusivity. Examples include ceramics, carbon fibers, mother of pearl, and of course various precious metals. Montavon notes that all these are readily cut with a femtosecond laser, often with no need for post-processing steps such as tumble polishing.

The Result

Technocut has gone from strength to strength, with a successful business and a stellar reputation in the watch industry, plus an increasing demand for parts for other precision industries. With over 15 years of customer experience, Montavon summarizes, “Coherent proved to be exactly the type of dependable partner we needed. Indeed, our experience with the first machine in terms of its great reliability, cut quality, and throughput, all convinced us to eventually buy three more of the same machines.”

To learn more about Technocut and the Coherent MPS laser, read the full success story.

“Our experience with the first MPS machine in terms of its great reliability, cut quality, and throughput, all convinced us to eventually buy three more of the same machines."

— Julien Montavon, Technical Director, Technocut, Bonfol, Switzerland