The Future is Clear with ZnS MS

The broad transmission range of Coherent zinc sulfide multispectral improves SWaP-C for aircraft reconnaissance systems.

May 14, 2024 by Coherent

A typical airborne imaging and sensing instrument array requires one or more windows in the aircraft fuselage.

Modern military aircraft often carry several imaging and sensing systems that gather visible and infrared light. These can be used for functions as varied as navigation, surveillance, reconnaissance, targeting, tracking, terrain mapping, and more. Similar systems are also used for commercial and scientific purposes, supporting applications like weather tracking, climate monitoring, environmental assessment, and agricultural analysis.

Typically, these sensing systems are located inside the fuselage and view the outside world through a window that is mounted flush with the aircraft skin. This is done to minimize aerodynamic drag.

But aircraft designers strive to use the fewest possible number of these windows. One reason for this is that putting ports in an aircraft fuselage complicates the design process. Specifically, each must be tested and qualified to ensure that it does not impact airworthiness. The more windows, the more testing required.

Another important factor is that the proliferation of these various sensing systems (and their associated windows) negatively impacts the size, weight, power consumption, and cost of the aircraft. Optimizing these factors, collectively called SWaP-C, is a key design goal today for military systems of all kinds.

Swapping Complexity for Simplicity

The designers of aerospace imagers and sensors tackle the SWaP-C challenge in a couple of ways. The first is to create “multispectral systems.” These combine the functionality of what would otherwise be several individual systems, possibly operating at diverse wavelengths, into a single, more compact, more economical package.

The second approach is to have more than one instrument share a window. This cuts down the number of fuselage ports required, and all the attendant testing and qualification.

These two approaches are often used in combination. But both require a window (and possibly other optics) that transmits well at all the operating wavelengths of the various systems peering through them. And depending upon how many systems use the same port, this window may have to be fairly large.

ZnS MS Spans the Spectrum

There are very few materials that transmit well in both the visible and infrared. Sapphire transmits from the deep ultraviolet through to 6 µm, magnesium fluoride extends this to 7 µm, and calcium fluoride reaches all the way to 9 µm. Diamond surpasses them all and transmits up to about 50 µm. But it also has an absorption band in the mid-wave infrared (MWIR) right where some sensors operate. Plus, there are practical considerations in terms of the maximum size and cost for these various materials. Large diamond windows especially can get a little pricey!

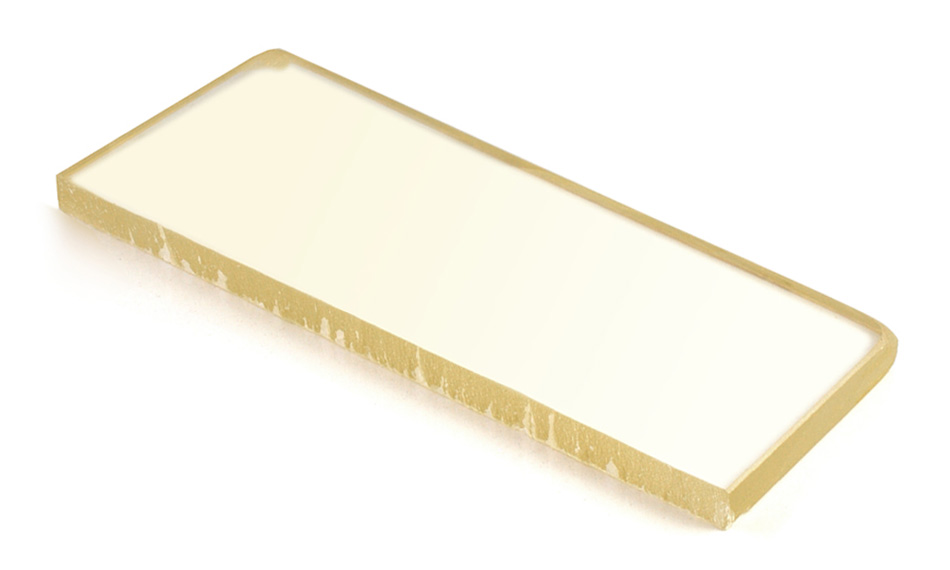

Unpolished ZnS MS.

Zinc sulfide multispectral (ZnS MS) has emerged as the most useful among all these materials. It transmits from 400 nm to 12 µm, which encompasses the entire visible spectrum and extends through most of the thermal infrared. This makes it compatible with nearly every electro-optical and infrared sensing system currently in use.

ZnS MS can also be produced in large sizes. Coherent routinely manufactures windows of up to 533 mm x 533 mm x 35 mm — dimensions large enough to meet the vast majority of airborne system requirements.

Making it Clear

But what is Zn MS, and how is it made? Zinc sulfide (ZnS) is a naturally occurring mineral which can have either a cubic or hexagonal crystalline structure and virtually always contains large amounts of iron and other impurities. As a result, naturally occurring ZnS is either very dark in color, or completely opaque.

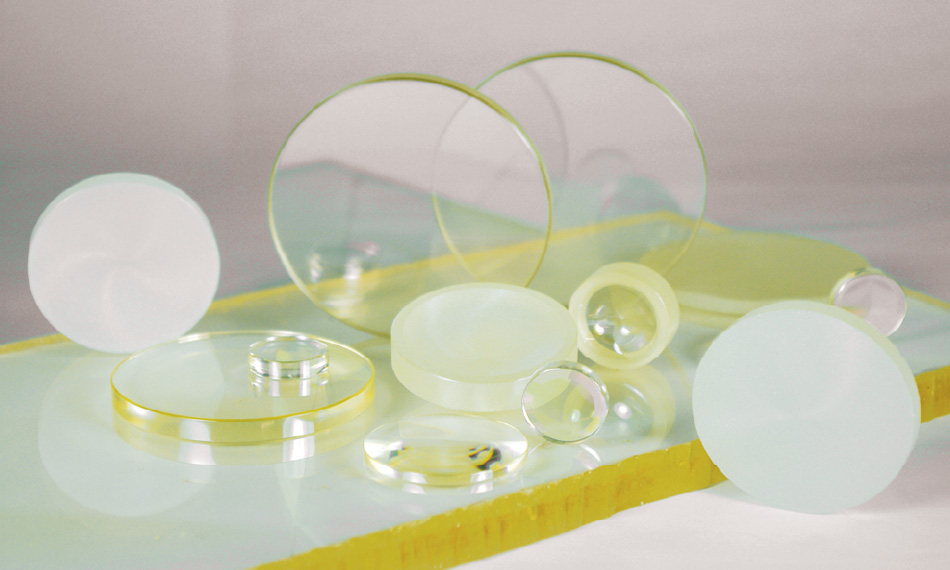

ZnS MS can be cut and polished into a wide range of sizes and shapes.

But pure ZnS is clear; it transmits visible and infrared light extremely well. Beginning in the 1950s, scientists explored producing pure ZnS under laboratory conditions. While they were able to grow the material using chemical vapor deposition (CVD), even these much purer laboratory-grown ZnS crystals still didn’t transmit all visible light. They usually appeared orange or red to the eye.

It turned out that there were two reasons for this. First, there were still residual impurities in the crystals. Second, no matter how carefully the crystal growth process was controlled, the result still had a mix of both cubic and hexagonal phases. The hexagonal phase scatters light and isn’t isotropic (meaning its optical properties aren’t the same in all directions).

A major advance came in 1979 when the process of ‘hot isostatic pressing’ (HIP) was first applied to lab-grown ZnS. In HIP, a crystal is placed in a pressure vessel and subjected to both high temperature and high gas pressure. HIP converts essentially all of the hexagonal phase ZnS to the more desirable cubic phase, which improves the optical properties of the material.

But the real breakthrough came with the discovery that wrapping the crystal in platinum foil during HIP virtually eliminates impurities present in the original crystal. The result was ZnS MS, a material that transmits nearly all visible light very well.

Coherent is Big in ZnS MS

Coherent (originally as II-VI) was a pioneer in the development of commercial ZnS and ZnS MS. We have been producing the materials for over 30 years and are now the only US-based manufacturer of large-sized ZnS MS windows. We grow the material using physical vapor deposition (PVD), followed by HIP.

A multi-spectral sensor for airborne systems.

In addition to crystal growth, we can also polish it to tight tolerances and specifications. We produce flat (plano) windows as well as domes.

Plus, we offer a number of thin-film coating solutions that improve window durability and lifetime. We can even put conductive grid coatings on ZnS MS windows for EMI shielding purposes.

The unique, broad transmission range of ZnS MS makes it an invaluable tool for designers looking to simplify their imaging and sensing systems and minimize SWaP-C. Coherent continues to be the leading US manufacturer of ZnS MS, thus supporting the next generation of streamlined, multi-functional sensor systems for the most demanding applications.

Learn more about Coherent ZnS MS.