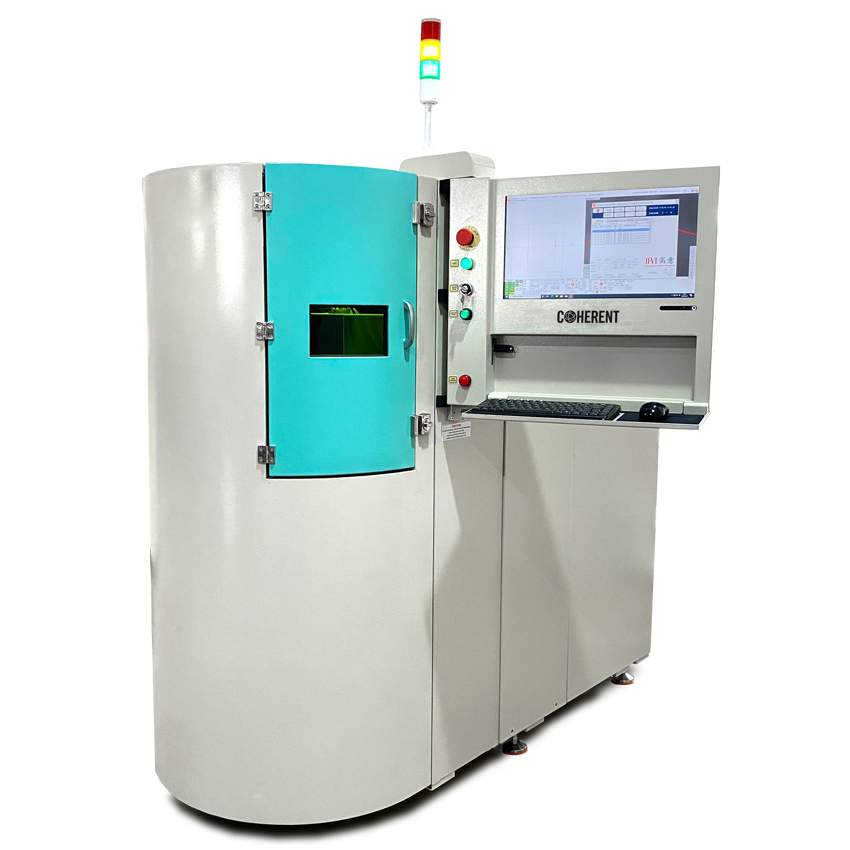

Laser Machines and Systems

L45/L60 PCD Surface Lapping/Shaping Tools

Obtain fast and efficient lapping of superhard PCD disks for tooling applications, as well as lapping, beveling, and rounding of PCD oil and gas parts.

A faster alternative to diamond powder grinding and EDM, the L45 enables surface lapping with a depth precision of 0.01 mm, where the depth can be set for each part within a single batch. The L60 can deliver deterministic shapes with no need for pre-lapping.

L45/L60 – Lapping and Shaping (PCD) Diamond Disks

L series tools feature high reliability, with key component lifetimes typically >10 years. They are environmentally friendly, with no escaped dust and noise below 75 dB.

Product Specifications

Model |

Processes Supported |

Lapping Precision (µm) |

Surface Accuracy (µm) |

Lapping Speed (mm/hour) |

Beveling Speed |

High single-run Throughput |

|

Number/size of pockets |

Max number of disks |

||||||

L45 |

Fine and Coarse Lapping |

10 |

0.2 (Ra) |

>1 for 60 mm diameter |

6 stack positions |

25 (5 mm thick) 40 (3 mm thick) |

|

L60 |

Lapping, Beveling, Rounding, Profiling |

0.5 mm/4.5 minutes |

100 pocket positions |

1613 parts total |

|||