What is Pulsed Laser Deposition?

Pulsed Laser Deposition (PLD) is used to deposit a wide variety of thin films onto a broad range of substrates. The high energy and short wavelengths of excimer lasers result in unmatched deposition rates and high-quality films with excellent stoichiometry.

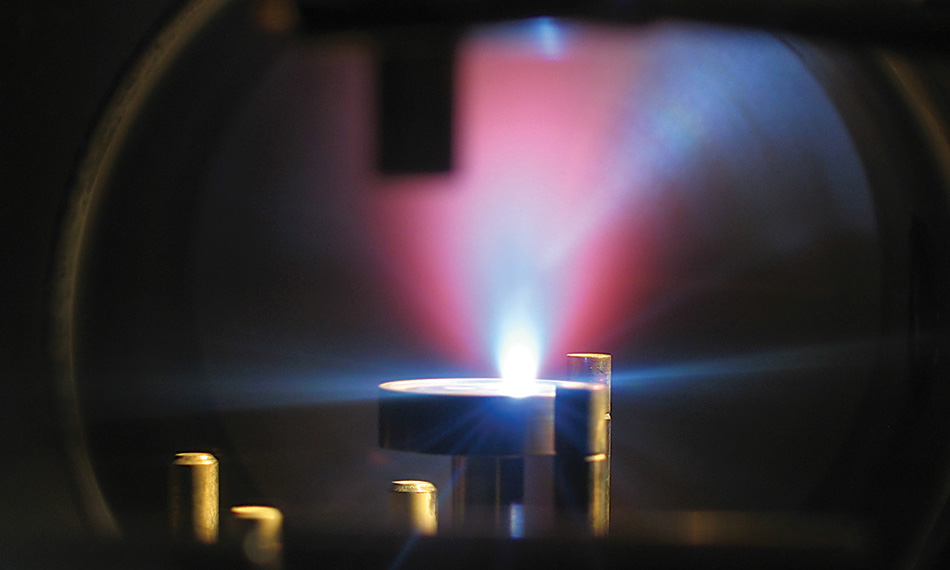

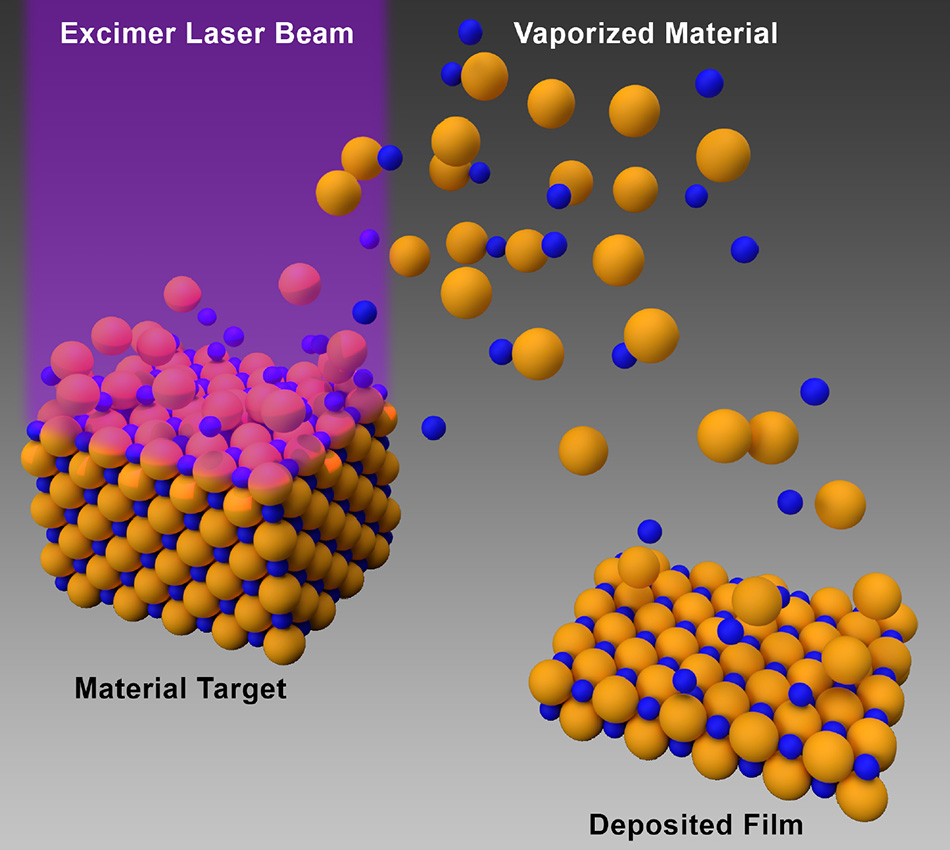

Pulsed Laser Deposition (PLD) is a physical vapor deposition (PVD) technique used to deposit thin films onto substrates under vacuum. In PLD, a laser pulse is directed onto a target material, causing it to vaporize and create a plume of vaporized material. This plume of vaporized material is then directed onto a substrate, where it condenses and forms a thin film.

Excimer lasers are the preferred lasers of choice in many PLD applications because their high pulse energy delivers thin film growth rates suitable for research through volume production. Just as important, the high photon energy of these ultraviolet lasers ensures unmatched film stoichiometry with all kinds of materials, which is a key requirement in most applications.

Stoichiometric deposition, what and why?

The importance of stoichiometry in PLD relates to the composition of the target material and the desired composition of the deposited film. Stoichiometry refers to the ratio of the elements in a compound, and it is a critical factor in determining the properties of the deposited film. In PLD, the original stoichiometry of the target material must be maintained in the film in order to obtain a film with the desired composition and properties.

For example, if the target material is an oxide, such as TiO2, the stoichiometry of the target must be carefully controlled to ensure that the deposited film also has the desired stoichiometry of TiO2. If the target material has a different stoichiometry, such as Ti1.5O2.5, the deposited film will also have this composition, which may result in a film with different properties than desired.

Overall, the importance of stoichiometry in PLD lies in its ability to control the composition and properties of the deposited film, allowing for the creation of films with specific desired characteristics for a variety of applications.

Stoichiometric PLD creates films with the same composition as the target.

Excimers – high photon energy and high fluence

In addition to controlling the stoichiometry of the target material, the laser energy and fluence (the amount of laser energy deposited per unit area) must also be carefully controlled in PLD in order to obtain the desired film properties. By adjusting the laser energy and fluence, the microstructure and morphological properties of the deposited film can be tailored to meet specific requirements. Excimers support a wide range of laser energy and fluence, with precise control over both. Coherent excimer lasers deliver uniquely high pulse energy resulting in the fastest possible deposition rates.

A growing range of diverse applications

The excellent stoichiometry and high deposition rates are the key reasons why excimer-based PLD is the only proven volume production method to make rare earth barium copper oxide (REBCO) films with the quality and quality needed for multilayer high-temperature superconducting (HTS) tapes.

However, PLD has a wide range of other important applications, including the creation of thin films for optical coatings, electronic devices, and biomedical applications. In optical coatings, PLD is used to deposit thin films with specific refractive indices, allowing for the creation of coatings that can manipulate light in specific ways. In electronic devices, PLD is used to deposit thin films of semiconducting materials, such as silicon, for the fabrication of solar cells and other electronic devices.

PLD is also very useful for producing thin films of transparent conductive oxides (TCOs) which form the front-side electrodes of photonic devices that detect or emit light.

PLD also has applications in the biomedical field, where it is used to deposit biocompatible thin films for use in medical implants and devices. For example, PLD can be used to deposit hydroxyapatite, a biocompatible material that is similar to the mineral component of bone, onto implant materials, such as titanium, to promote bone growth and improve the biocompatibility of the implant.

What about other methods?

In addition to its wide range of applications, PLD also offers several advantages over other thin film deposition techniques. PLD allows for the deposition of high-quality thin films with good crystallinity, and it has the ability to deposit films at high deposition rates. PLD also enables the deposition of films with a high degree of control over film composition and microstructure, making it a valuable tool for the creation of thin films with specific desired properties.

Additionally, PLD has the ability to deposit films on a wide variety of substrate materials, including metals, ceramics, and polymers. This versatility allows PLD to be used in a wide range of industries and applications, making it an important tool for material science and engineering research.

What are the practical challenges with PLD?

One of the challenges of PLD is that it requires specialized equipment, including a laser source, target material, and a vacuum chamber. The cost and specialized nature of this equipment can limit the widespread adoption of PLD in some industries.

Another challenge of PLD is the complexity of the process. The laser energy and fluence, target stoichiometry, and substrate temperature must all be carefully controlled in order to obtain the desired film properties. This requires a high degree of technical expertise and can limit the ability of some researchers and manufacturers to utilize PLD.

Bottom line on PLD

Despite these challenges, PLD continues to be a widely used and valuable technique for the deposition of thin films. Its ability to deposit high-quality films with specific desired properties has made it an important tool in a variety of industries and applications.

In summary, PLD is an important technique for the deposition of thin films with specific desired properties. Its versatility and ability to deposit high-quality stoichiometric films make it a valuable tool for material science and engineering research and for the development of a wide range of thin film industrial applications, including optical coatings, electronic devices, and biomedical applications.