WHITE PAPER

Rare Earth Doped Fiber Enable NIR Lasers and Amplifiers

Lasers and laser systems based on specialty optical fibers doped with rare earth elements represent one of the most successful dual-use photonic technologies of recent times, with applications from welding “difficult” metals in e-vehicles, to precision laser targeting, to cutting medical devices. In this document we describe some of the specialty fiber options that play important roles in a complete fiber laser system.

Rare Earths Enable Near-IR Laser Operation

Doped materials containing positive ions of a rare earth element, e.g., Ytterbium (Yb), Neodymium (Nd), Holmium (Ho), Thulium (Tm), and Erbium (Er) provide output in the near-infrared (NIR) 1-2 microns wavelength region. This is a useful operating range because many materials strongly absorb here, enabling efficient materials processing applications including, drilling, cutting, welding, and marking. In addition, the onset of strong light absorption by water at wavelengths around 1400 nm make wavelengths longer than this useful for medical (e.g., surgical ablation) applications while enabling remote fiber delivery. Because of this water absorption, 1400 nm is generally regarded as the cut-on wavelength for eyesafe lasers; longer wavelengths are safely absorbed by water on the outside of the eye and don’t penetrate to the retina. This makes these invisible wavelengths useful in applications such as lidar imaging and range finding. The laser wavelength can also be shifted to the visible or ultraviolet using a non-linear optical crystal.

Fiber Lasers Avoid Thermal Management Issues

While these ions can be doped into a variety of crystalline and glass materials, today the majority of their laser applications use a fiber laser format, where the ions are doped into silica glass optical fiber. In addition to providing mechanical stability, compared to free-space optics, fiber lasers don’t have the heat dissipation problems of bulk formats such as rods and slabs. This has enabled the output power of fiber lasers to be scaled from watts to over 10 kilowatts. Their wide power range is a key reason for the diversity of applications for these lasers.

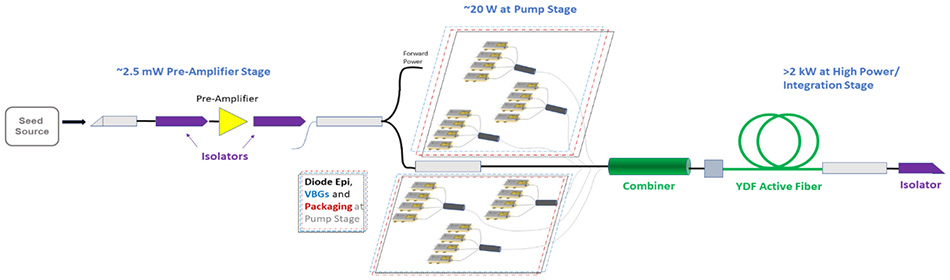

Figure 1: The main elements of an amplified fiber laser system.

Figure 1 schematically illustrates the main components of an amplified fiber laser system. The gain medium is an active fiber doped with positive ions of a rare earth element, e.g., Nd, Er, Yb, Tm, or Ho. These are directly pumped by diode lasers enabling compact and electrically efficient laser systems. Other key components include additional lengths of active (doped) fiber that act as amplification stages, optical isolators to prevent harmful back reflections, Fiber Bragg Gratings that act as cavity mirrors to support laser oscillation, crystals to generate harmonics or shifted wavelengths, and passive delivery fibers.

Rare Earth Doping Options

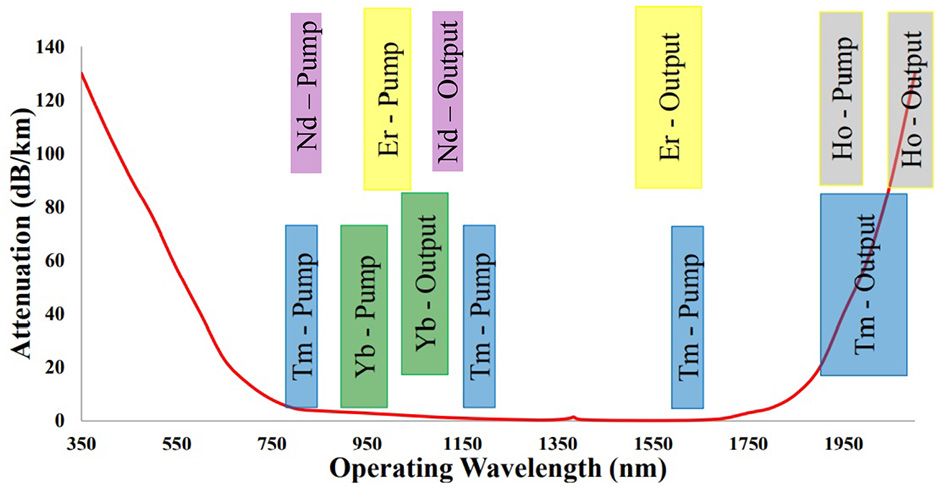

Glass (silica) fibers can be doped with ions of several different rare earth elements. Coherent offers a comprehensive range of doping and options since the optimum choice depends on both the desired wavelength, power level, and pulsing parameters. Figure 2 summarizes the wavelength characteristics of the five commonly used rare earth ions Nd, Er, Yb, Tm, or Ho: both the emission wavelengths and the requisite pumping wavelengths. Yb is increasingly popular in ultra short pulse (USP) lasers because its relatively broad emission bandwidth supports mode-locked fiber lasers with pulses as short as 50 femtoseconds and amplified (i.e., high power) systems with pulses of just a few hundred femtoseconds (fs).

Figure 2: The wavelength characteristics of the five commonly used rare earth ions Nd, Er, Yb, Tm, and Ho. The red curve shows the attenuation of the glass host used in the fiber.

Coherent also offers specialty optical fiber co-doped with both Er and Yb. The Er acts as the gain medium, resulting in emission around 1550 nm, depending on the doping concentration. The Yb acts as a light absorber, preventing unwanted amplified spontaneous emission around 1 micron, ensuring a laser system that is completely eyesafe.

Rare-earth doped fibers can also be additionally doped with a “modifier” element such as Aluminum (Al) Germanium (Ge) or Phosphorus (P). These are used primarily to manipulate the refractive index of the fiber, which enables the numerical aperture (NA) to be modified somewhat independently of the core diameter of the fiber. The NA defines the spread angle of light emitted from the fiber and the angular range over which light can be focused into the fiber. It is important since it is often the limiting factor in how the laser can be focused or projected by downstream optics.

Diverse Fiber Options

Just like other optical fibers, rare earth doped active fibers are also classified by their transmission mode as determined by the optical details of their core and cladding.

Core: The core ranges from 10-200 microns in diameter and is surrounded by a cladding of a glass with a slightly lower index. This arrangement confines the light to the fiber because of total internal reflection and only the core is doped with rare earth ions. Most fibers can be assigned to one of three types: single-mode (SM), multi-mode (MM), and large area-mode (LMA). SM fibers have the smallest diameter inner core so that there is only one transmission mode, which is often desirable because it results in an output beam with the best focus ability, i.e., to the smallest spot. MM fiber is the next most common fiber type, supporting approximately 1000 different transmission modes. This supports higher power output but with a less focusable beam and is mainly used to handle the pump light from the diodes. LMA fibers are an important niche type for use in very high power systems.

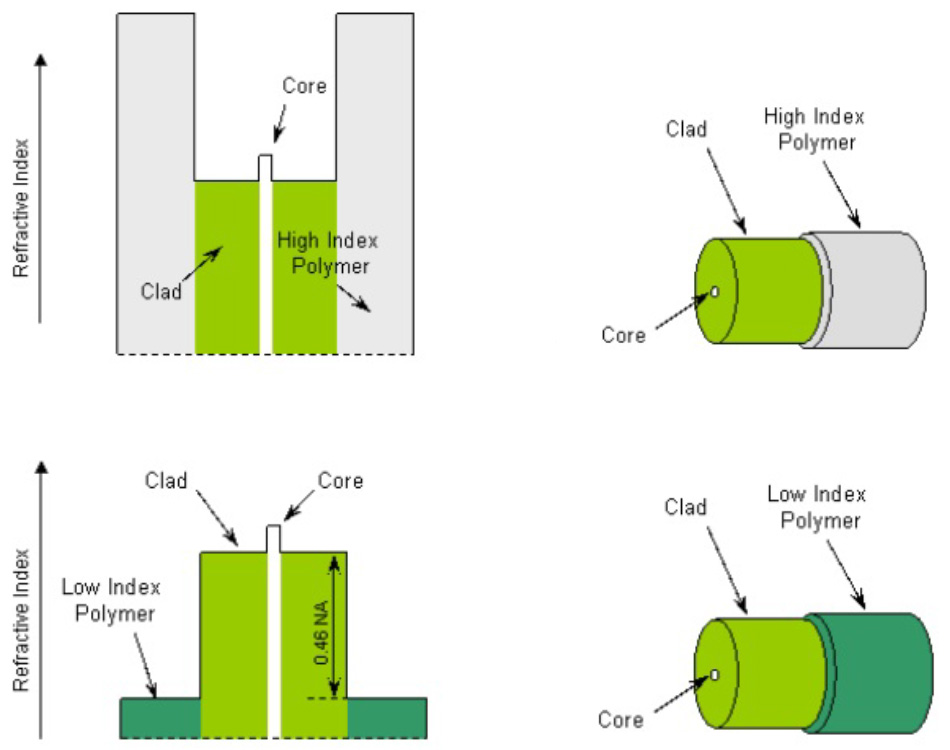

Cladding: Doped fibers are available with two different cladding options. The simplest format is called single-clad fiber where the core is slightly higher index than the cladding which is then surrounded by a protective coating of a index polymer. In double-clad fibers, the inner cladding is surrounded by a coating of a low index polymer. Double-clad fibers increase the ability of the core to absorb light by allowing higher input pump powers and enhancing interaction between the pump light and the active rare earth ions in the core. Coherent also offers triple-clad fibers that support most fiber interconnect systems and diode laser power delivery systems and offer radiation resistance in space-based applications.

Figure 3: The two most commonly used cladding options are single-clad and double-clad.

Full Range of Specialty Optical Fiber Options

To summarize all the choices, rare earth doped fibers are available as standard products from Coherent with a choice of five different rare earth ions: Nd, Er, Yb, Tm, or Ho They are available as single-mode (SM), multi-mode (MM), and large area-mode (LMA) fibers, all with several choices in both the numerical aperture (NA) and the core diameter. Plus, the full product line includes single-clad, double-clad, and triple-clad fibers. Altogether this encompasses thousands of different standard doped fibers. OEM systems builders can also work with Coherent to define fiber specifications for custom applications.

Superior Performance for Demanding Applications

Coherent rare earth doped fibers are ideal for both laser and laser amplifier applications over a wide power range. For instance, our high-quality fibers eliminate two of the well-known challenges in fiber amplifier power scaling: Stimulated Raman Scattering (SRS) and Transverse Mode Instability (TMI). They feature high mode quality, excellent pump light absorption, long lifetime, and exceptionally low photodarkening. As a result, they provide reliable, extended operation in even the most demanding industrial, medical, space and lidar applications.

Vertical Integration – Components Through Complete Laser Systems

Coherent is a vertically integrated photonics company manufacturing a complete range of active and passive optics and components, lasers, and complete laser-based machines. This starts with an unmatched offering of diode lasers, including VBG-locked diodes that use our own VBG filters. We also make Fiber Bragg Gratings (FBGs), optical isolators and rotators, and passive beam delivery fibers. We even grow our own non-linear crystals in a US facility. In fact our US-sourced components alone range from semiconductors to domestically grown crystals, as well as optical fibers, lasers, and optics. Altogether, this means Coherent is now the largest US producer of domestic lasers, windows, and pump diodes. In addition to offering all these critical separate components, Coherent also has decades of experience as a supplier of laser subsystems and complete systems. So if you’re involved in laser systems based on rare earth doped fibers for any application, Coherent can support you with the exact level of integration you need to successfully execute a cost-effective program with results that exceed expectations every time.