Laser Micro Welding Solutions for Line builders and Integrators

With the PowerLine FL, Coherent delivers a precision welding subsystem package with the knowhow and support to ensure success.

March 27, 2024 by Coherent

Quickly produce small, strong, cosmetically attractive welds with minimal heat affected zone for pressure sensors, batteries, mobile devices, and other products.

There is an increasing demand for precision metal micro-welding across several industries. Micro welding generally encompasses weld depths of around 1mm (0.04”) or less. This is being driven by various dynamics, including increased welding speed, the use of dissimilar materials and easy line integration. Typical welding examples are found in automotive battery assembly such a thin tab-to-terminal welds, a variety of small consumer products, and surgical instruments for medical device manufacturing.

While lasers have often emerged as the production tool of choice for these tasks, new demands of production extend beyond the laser process itself to automation, vision, in-process monitoring, data gathering, and a single encompassing control software.

Delivering the application

It all starts with the application, and our applications labs will define the equipment needed for the application and production requirements. The application is “delivered” with the subsystem that de-burdens our customers and accelerates time to market. Training is also offered to ensure there is a seamless process handover.

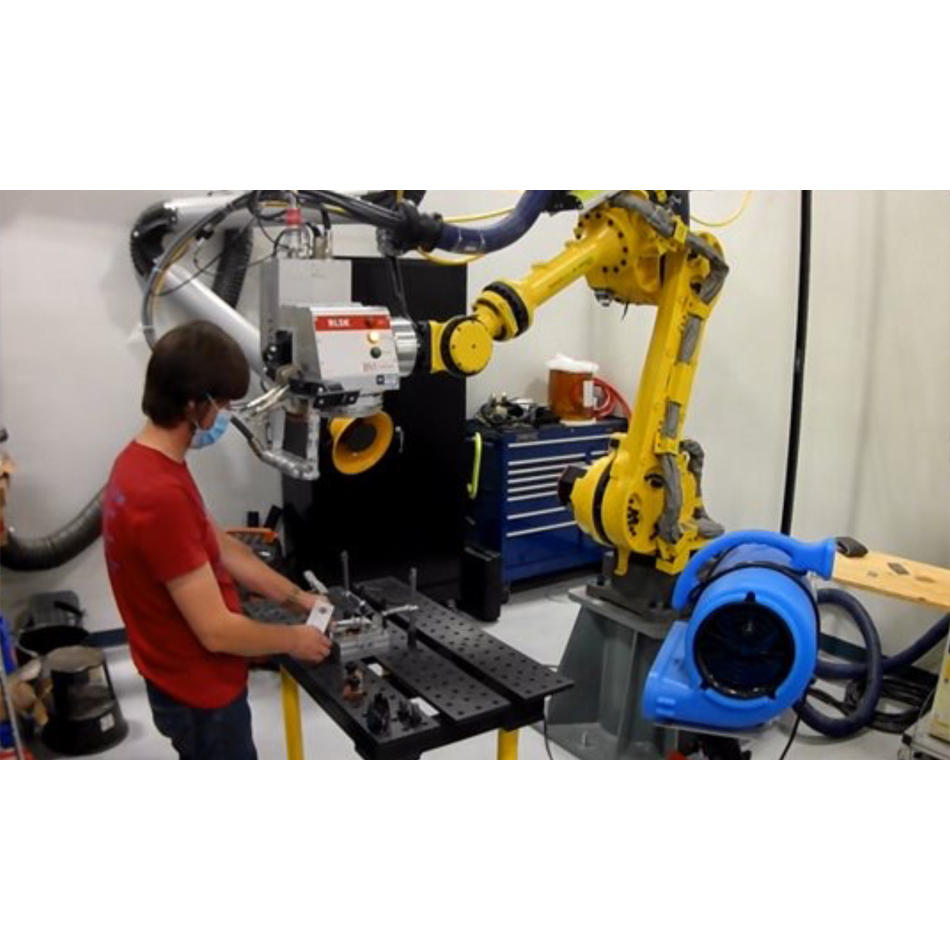

Copper contacts welding with PowerLine FL and integrated scanner processing head.

Beyond the Weld

After developing a robust welding process in the lab there are the demands of production, and specifically weld joint location, welding path variation, and part fit-up tolerances. These necessitate the use of vision that can provide a pre-weld G/NG as well as making motion corrections for these variations on-the-fly.

The key requirements for a welding subsystem are simply programming, easy integration and supporting process data manufacturers migrate toward Industry 4.0.

See the Difference

To achieve high yields and quality for precision welding tasks, it’s essential to identify part location, variations in the part positioning, and where possible part fit-up.

Our vision package has an embedded library of vision options that work with standard illumination sources to enable an easy implementation for the part, geometry, and lighting. The vision package is fully integrated into the control software for simple setup that enables part confirmation and positioning for every single weld on every part.

Smart Laser & Process Monitoring

The only way to be 100% certain a weld is good is to pull it apart to measure its mechanical strength and cross-section integrity. Of course, this approach isn’t so great for production yield!

The goal, then, is to have automated, non-destructive monitoring that provides a reliable go/no-go assessment. Our solution to provide data for this assessment is Coherent SmartSense+.

An in-line process weld monitoring system which collects light from the weld and uses AI-based algorithms to provide information on G/NG and potentially what the error might be.

The SmartSense+ process monitoring method uses in-house developed technology for welding applications that integrates seamlessly with the Laser FrameWork control software. It provides options for data storage, access, and transfer to local databases.

PowerLine FL: precision laser welding and cutting with a ready to integrate package with laser, processing head, vision and/or process monitoring, all from one supplier.

The Complete Package

But, the added value of PowerLine FL, or any other Coherent welding solution, is that you don’t need to worry about any of these considerations. Coherent Application Labs and our product engineers have the resources and expertise to develop and deliver you a process, as well as define the equipment to get the job done. And we know what works, what doesn’t, what’s risky, and what isn’t. Finally, our vertical integration means you’re going to get a complete solution all from one vendor, which eliminates any ‘finger-pointing’ if issues arise in production. The result isn’t just a successful process – it’s peace of mind.

Learn more about PowerLine FL, and other Coherent laser welding systems.