Securing the Battery Supply Chain

From Li-ion battery recycling to Li-S battery chemistry, Coherent paves the way for the future of EVs.

October 20, 2023 by Coherent

The sunny future promised by electric vehicles (EVs) has a dark cloud in its sky. It’s the rechargeable lithium-ion (Li-ion) batteries that sit at the very heart of EV technology. And, for that matter, at the center of most other electronic devices that power modern life.

A primary concern with Li-ion batteries stems from two of the elements used to manufacture their cathodes (the positive terminal of a battery) – cobalt and nickel. Sourcing these elements depends on fragile and ethically challenged supply chains.

Reducing impact through Li-ion battery recycling

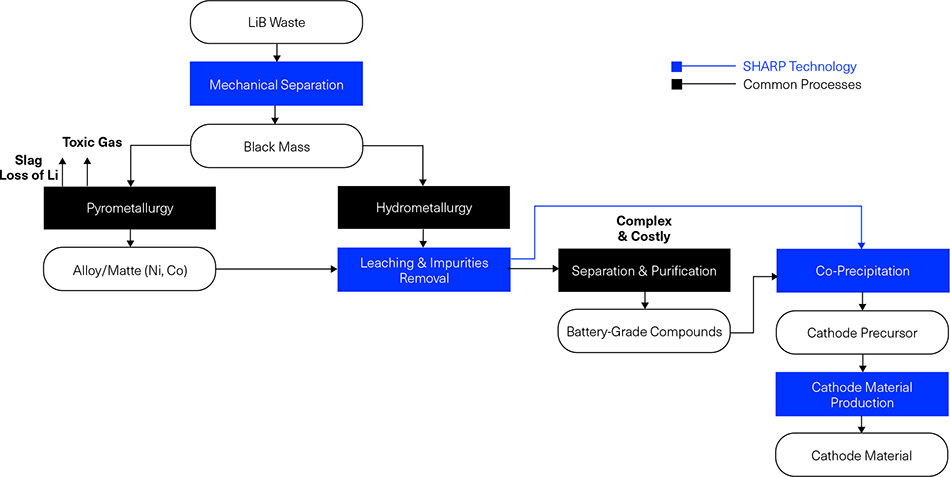

One strategy for minimizing the supply chain, cost, and environmental issues associated with Li-ion batteries is efficient recovery and recycling of nickel, cobalt, and other chemicals from end-of-life batteries. Specifically, recycling reduces the pressure on mining raw material.

Our Streamlined Hydrometallurgical Advanced Recycling Process (SHARP) technology provides an environmentally friendly, cost-effective means to recover critical metals from used Li-ion batteries.

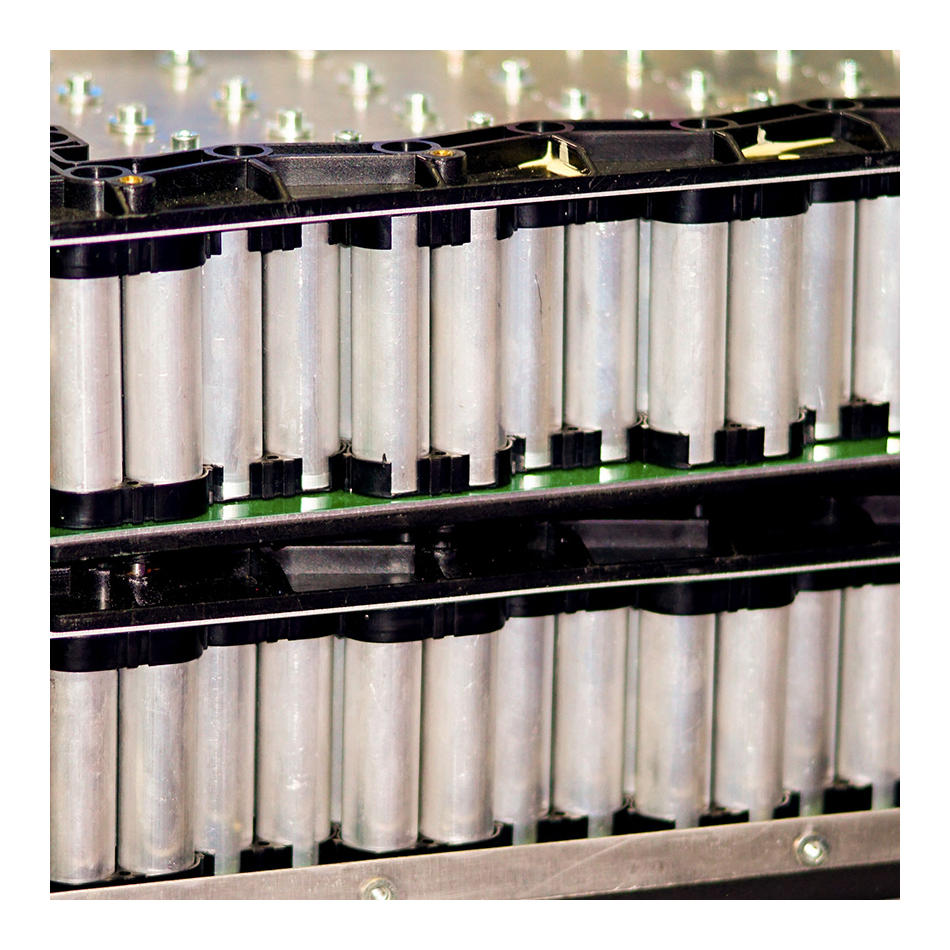

Efficient recovery and recycling of nickel and cobalt from end-of-life Li-ion batteries is one way to reduce the need for mined raw materials.

Our Li-S battery chemistry alternative

Another approach is to develop alternatives to lithium-ion chemistry that use abundant and more easily obtainable materials to deliver higher battery performance at a lower cost. Many leading companies in battery research are actively working on this. Changing the chemistry has the potential to introduce supply chain resiliency and ultimately make EVs more affordable and appealing to consumers.

Lithium-Sulfur (Li-S) battery chemistry has emerged as one viable future path. This technology uses sulfur as the cathode active material (CAM), rather than the various cobalt, nickel, and other metal oxides used in Li-ion batteries.

Sulfur is desirable as a CAM for several reasons. First, it’s readily obtainable (it’s the fifth most abundant element on Earth) and therefore inherently less costly than cobalt or nickel. It is also widely mined and produced as a byproduct in less geopolitically problematic countries that have already emerged as battery manufacturing hubs. This lowers transportation costs. Together, these could substantially reduce the price per kilowatt-hour for a battery.

Furthermore, a Li-S battery can also hold more energy than a Li-ion battery. It’s estimated that a Li-S battery can hold twice the energy of a Li-ion battery of the same weight. This could mean EVs with either a greatly expanded range or much lighter weight.

So, Li-S offers performance and cost advantages over Li-ion and has an inherently more secure supply chain. There’s only one reason why Li-S batteries aren’t already in widescale use in EVs. They don’t work.

The Selenium-to-Sulfur Breakthrough

The technical problem with Li-S batteries stems from the chemical reactions that occur inside them. Specifically, sulfur goes from a solid to a liquid – and then back to a solid – during the charge and discharge cycles. Some of the sulfur stays in the electrolyte causing an irreversible loss of capacity. This dramatically reduces the charge capacity with each cycle.

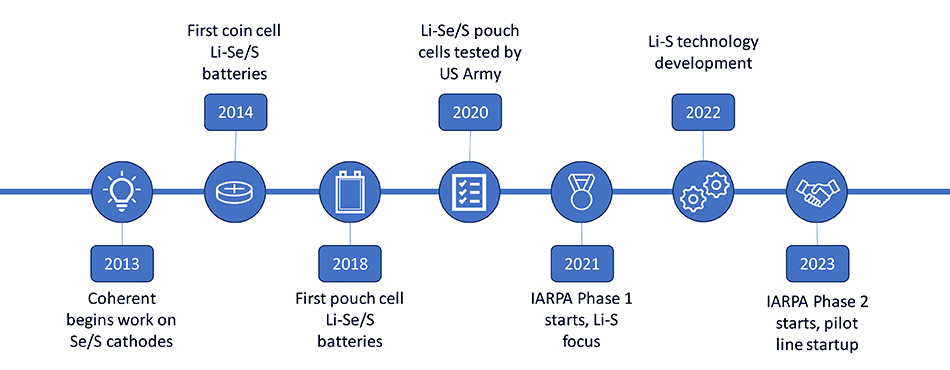

Solving this problem has been the focus of Li-S battery researchers for many years. Coherent has been working on it internally for a decade.

Our initial work focused on Li-Se (selenium) chemistry. Selenium and sulfur are both elements in Group VI of the periodic table. And Coherent has a lot of expertise in working with Group VI materials. That’s why the company was originally called II-VI!

Our team changed their focus from selenium to sulfur in 2020. And now we have made significant breakthroughs that solve the issue. This enables us to produce Li-S batteries (or more specifically ‘sulfur cathodes’) that can hold a charge at or near the theoretical limit for the material. And our cathode is “cyclable.”

The groundbreaking Li-S battery technology developed by Coherent is the culmination of a decade of research within the company.

Of course, there are other groups working on Li-S batteries. Some of them have also achieved performance characteristics similar to ours.

However, our technology offers one major difference and critical advantage over these others. Our innovations are applied to bulk materials at the cathode composite and slurry levels. What this means is battery manufacturers can utilize our materials with their existing cathode production processes without tooling changes.

Given the massive amount investment in battery manufacturing capacity built around Li-ion chemistry, we believe that it is essential to offer manufacturers a smooth transition to Li-S. The Coherent Li-S technology extends the lifespan of the capital expenditures being made today.

Everyone is Driving Towards Li-S

The potential of Li-S and the recent advances in the technology (by Coherent and others) are no news to anyone in the battery or EV industry. It is widely recognized in these communities that Li-S will eventually displace Li-ion. The United States Department of Energy also maintains this view. They are developing Li-S technology at National Laboratories and funding commercial research.

With our unmatched experience in Group VI materials and positive results to date, Coherent is well-positioned to take a leading role in the deployment of Li-S technology. We are commercializing this technology today with the materials and processes necessary to establish a starting point for manufacturers. These could include manufacturing CAMs, producing finished cathode components, and licensing our technology.

But no matter how we participate in the Li-S battery market, Coherent has already delivered key innovations that make sulfur cyclable in a way that incurs minimal cost and mass penalties. These will help transition the battery industry to materials with much greater supply chain security. And this will lower the barrier to mobile electrification, clearing the skies for the future of EVs.

Learn more about Coherent Li-S technology.