Automotive Manufacturing

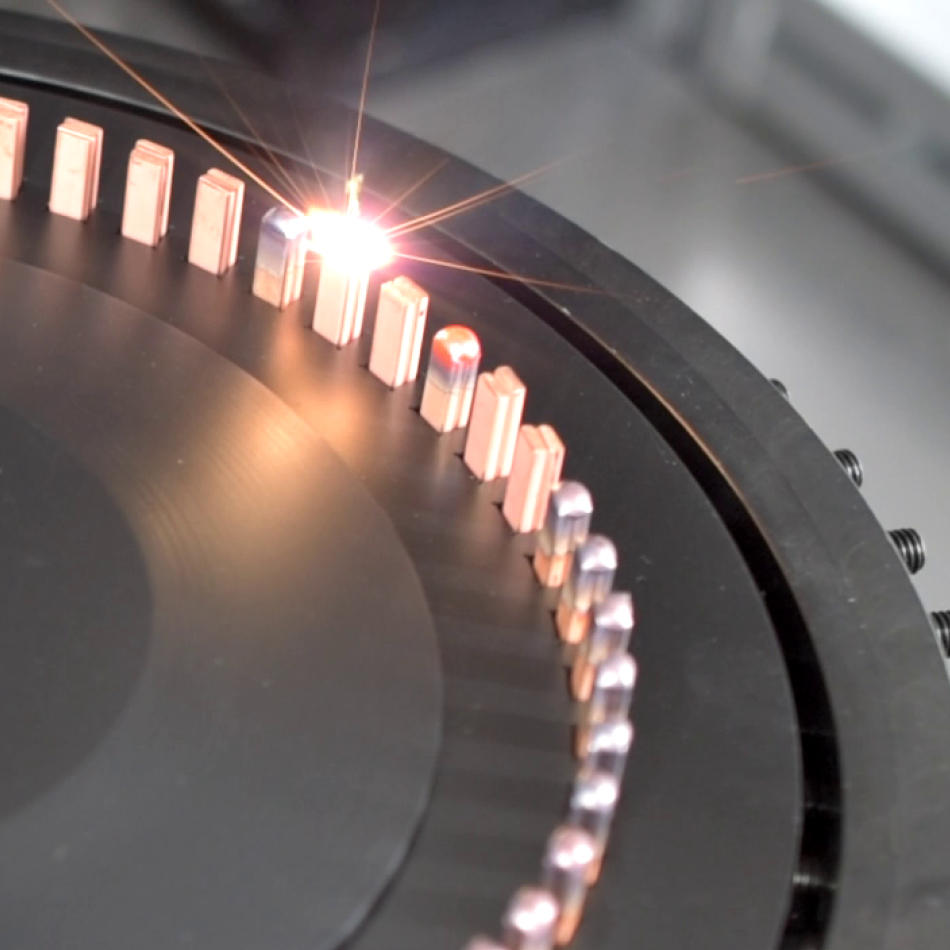

Driving innovation

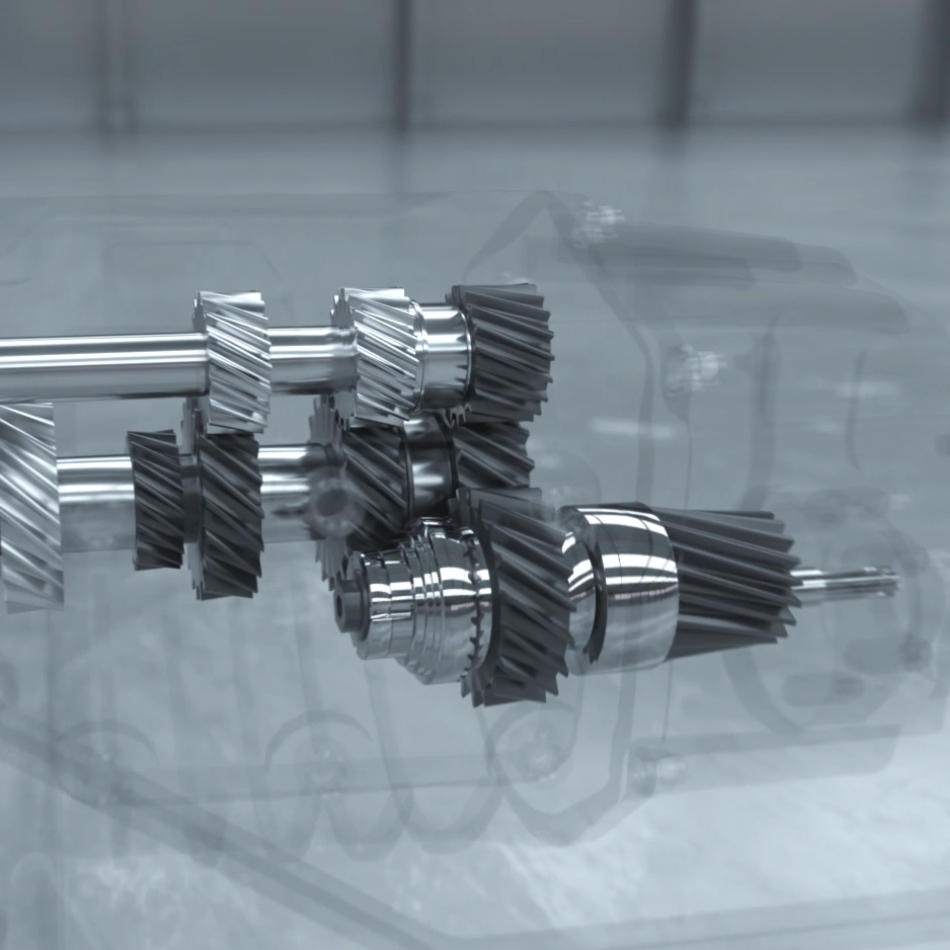

Meet EV production challenges with cutting-edge technology that improves performance and reliability, and also lowers costs.

Featured Blog

SiC power electronics improve EVs

Discover why SiC power electronics are in demand for improving EV performance.

Ready to Get Started?

Share your contact info and a specialist will reach out.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.