Laser Measurement Instruments

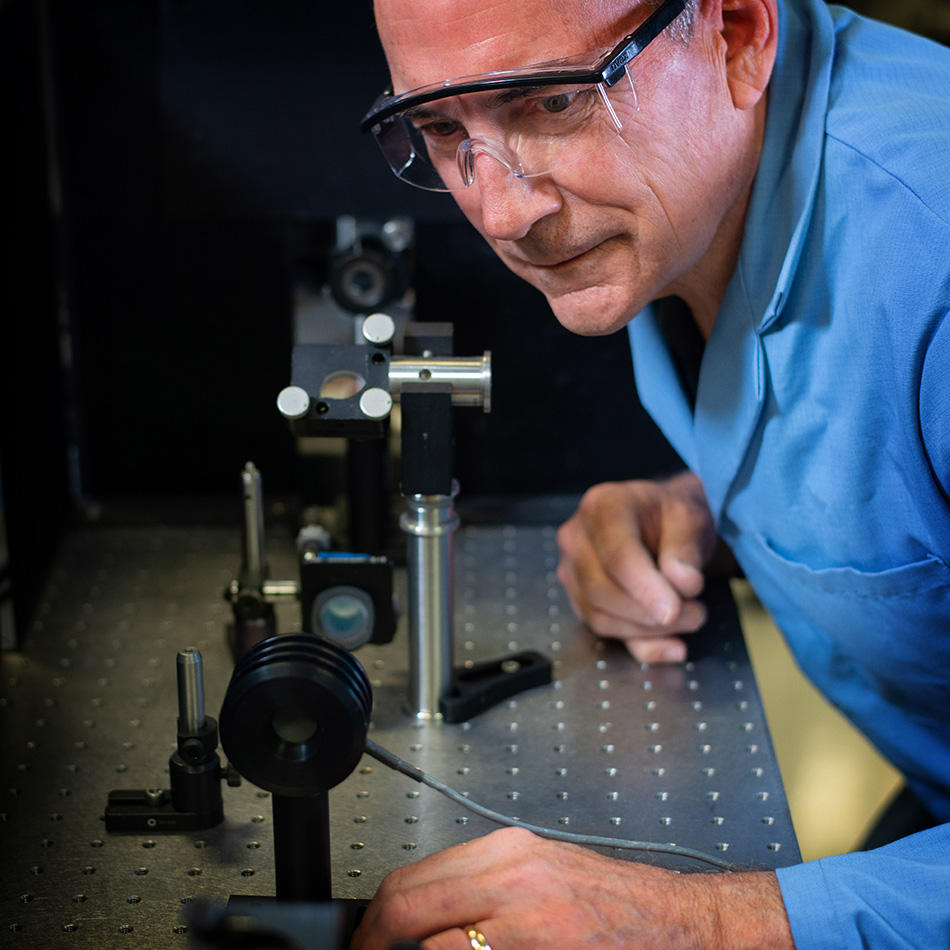

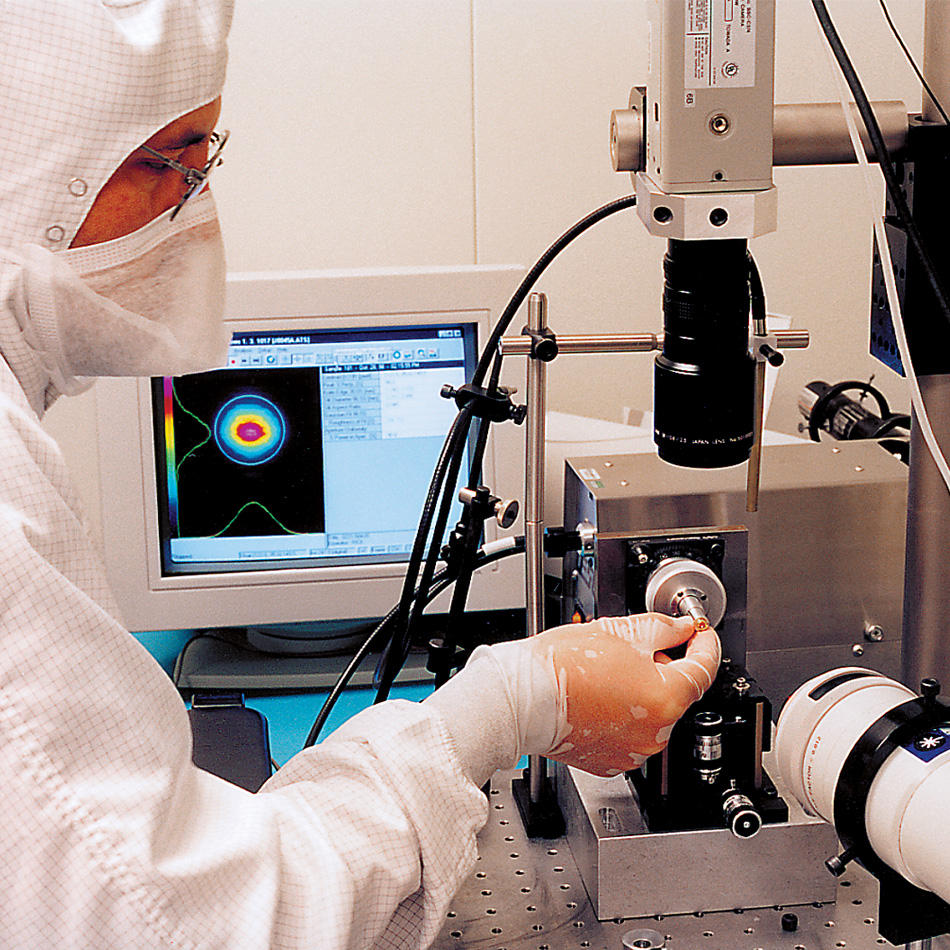

Accurate measurements and diagnostics

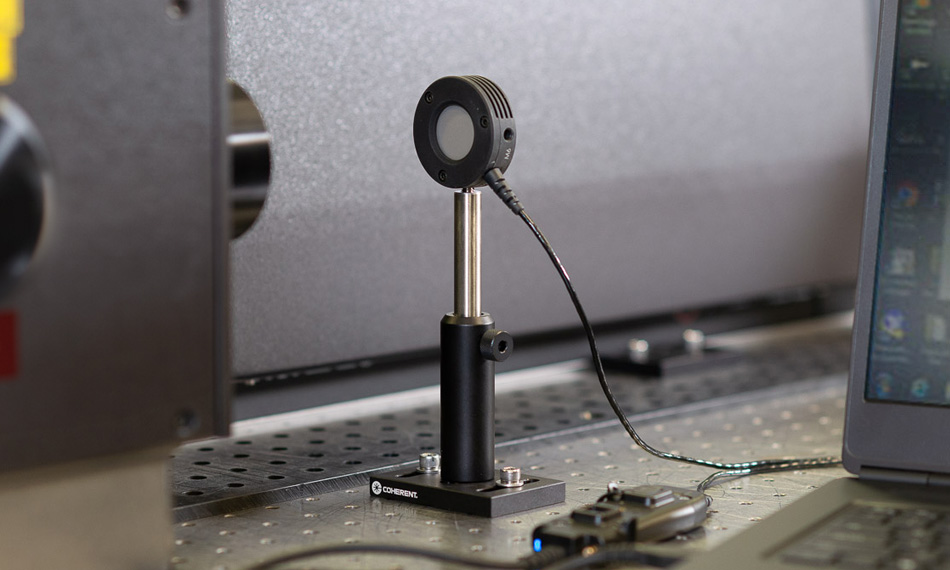

Wide-ranging line of laser power and energy measurement products that deliver accurate, ISO/IEC 17025 certified measurements, and laser beam diagnostics systems that measure spatial intensity distribution and beam size. All backed by more than 50 years of industry experience, with worldwide service and support.

- Quality & Reliability Backed by superior reliability (<1% warranty rate) and more than 50 years of industry experience.

- Accuracy Calibrations accredited to the ISO/IEC 17025:2017 calibration laboratory standard.

- Fast Delivery Look for the 1 Day Ship badge to identify products available for next day shipment.

Not sure which absorber coating you need?

Use our damage threshold calculator to input your laser parameters, calculate the power and energy densities, and compare damage limits of different sensor coatings.

Additional Laser Measurement Resources:

Solution Briefs

- Why Is My Sensor Out of Tolerance?

- Care and Handling of Your Coherent Sensor

- Damage Threshold of kW Thermopile Power Sensors

- Justifying Single Point Calibration

- LabMax-Pro PC Data Collection

- LaserCam HR II "Ghosting Images"

- OEM Sensor Communication and Supply Connections

- PowerMax-Pro kW Push to Connect Fittings

- Understand a Certificate of Calibration

- What is the Accuracy Specification for Positioning on my LM Sensor?

- Flow Rates and Fittings for Water-Cooled Sensors

- PMK+ Coating Details for Power Measurement

White Papers and Guides

- BeamView.NET

- Novel Laser Power Sensor Improves Process Control

- LabMax Laser Power and Energy Meters

- Understanding ISO 17025 for Laser Power and Energy Measurement

- Meterless Laser Power/Enery Measurement Simplifies Embedding

- Laser Additive Manufacturing

- PowerMax-Pro Cleaning Guide

- PowerMax-Pro: Energy Readings Using Host SCPI/Commands

- PowerMax: Energy Readings with LabMax-Pro

- Thermopile Power Sensors: FAQs, Troubleshooting, Care

Traceability Charts

Ready to Get Started?

Share your contact info and a specialist will reach out.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.