加工头

改进和扩展材料加工应用中的焊接、铜焊和切割能力。

- 提高精度 实现更高的加工品质,较高的精度和改进一致性。

- 优化流程 通过易于配置或定制的产品来满足您特定应用的各项需求,从而获得更好的结果。

- 降低成本 缩短周期时间,消除后处理并减少返工。

提升生产力的应用解决方案

无论您需要焊接微小的电池组件还是切割 50mm厚的钢板,这些加工头都能将性能、可靠性、灵活性和易用性相结合,能够大幅提高您的工艺运行质量。 它们在执行各种要求苛刻的焊接、铜焊和切割任务中有成功良好的表现,比如电动汽车制造、汽车生产和造船等应用。 之所以能够胜任这些任务,是因为它们将高质量光学器件、坚固的机械结构、嵌入式传感器和板载智能与功能强大且易于使用的软件相结合。

需要我们处理材料样品? 想要亲自看看结果? 我们可以邀请您到附近的 Coherent 应用实验室参观。

焊接头和配件

适用于 Coherent PowerLine FL 或 ARM 激光焊接产品的精密焊接头,具有多种先进的光束摆动功能。 |

焊接异种或“具有挑战性”的材料(如铝、不锈钢和铜),适用于电动汽车和消费电子产品。

|

提供“智能”图型,包括简单的摆动、螺旋、椭圆和其他复杂形状。 图型大小和方向可以随意自由控制。 |

为新应用带来光纤激光器的经济性、便利性和可靠性。 |

高性能远程激光焊接头,包含扫描仪和 F-Theta 透镜。 |

在要求苛刻的应用(例如电动汽车制造)中提供高质量、可靠的焊接。 |

可与高达 8 kW 的传统光纤激光器和 ARM 光纤激光器配合使用,大小约 251 毫米 x 372 毫米。 |

借助多种选项,您可以按想要的方式配置它,包括交叉射流、过程监控、各种放大倍率和视觉。 |

3D(x、y 和 z 光束移动)远程激光焊接头提供卓越的功能,可实现复杂的焊接路径。 |

非常适合汽车车身和悬挂件制造。 为电池、电动机和动力总成组件的精密焊接提供高定位精度。 |

覆盖大型 3D 工作范围(最大 244 毫米 x 369 毫米,200 毫米 z 范围),且可以在几毫秒内到达任何位置。 |

焊缝跟踪选项能自动跟踪弯曲路径,并且在角焊和对焊时可以定义偏移量。 |

适用于 Coherent 远程焊接头的集成机器视觉解决方案。 |

可针对 3D 角焊缝跟踪、2D 焊接位置匹配、形状识别和发夹焊接进行专门优化。 |

专业的机器视觉算法可提供精确控制、高精度和快速检测时间。 |

图形界面简化了任务设置,例如定义过程限制和报错条件。 |

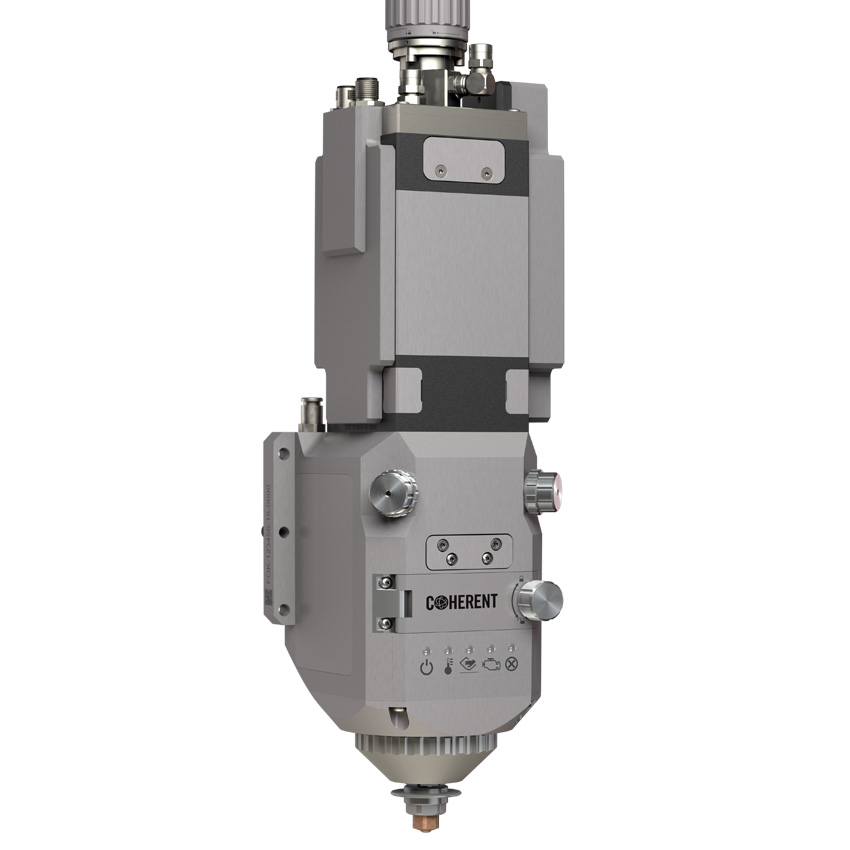

模块化激光加工头,适用于功率高达 20 kW 的高功率光纤耦合激光器,具备卓越的运行可靠性。 |

旨在为汽车生产、管道制造、能源等领域的大功率工业焊接作业提供一流的正常运行时间和可靠性。 |

使用众多可用模块和选件轻松配置完全符合您需要的加工头。 |

配备独特的变焦准直模块,可准确保持任何原始光束轮廓,包括“平顶”或 ARM 光束。 |

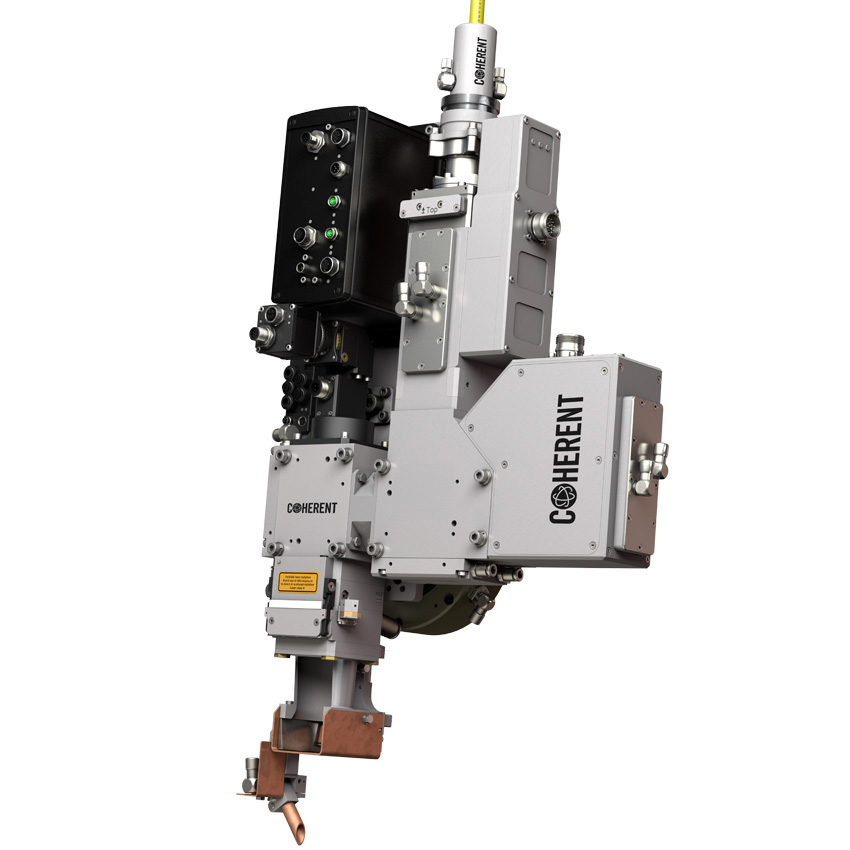

用于焊丝钎焊和焊接的触觉焊缝跟踪加工头,可提供优质的焊接结果和卓越的可靠性。 |

特别适用于汽车制造和电动汽车领域中要求严苛的焊接任务。 |

借助众多选项,可以轻松打造具有全部必需功能的加工头。 |

连续调整变焦和即时聚焦能力将软件控制焊接的灵活性和生产力提升到全新水平。 |

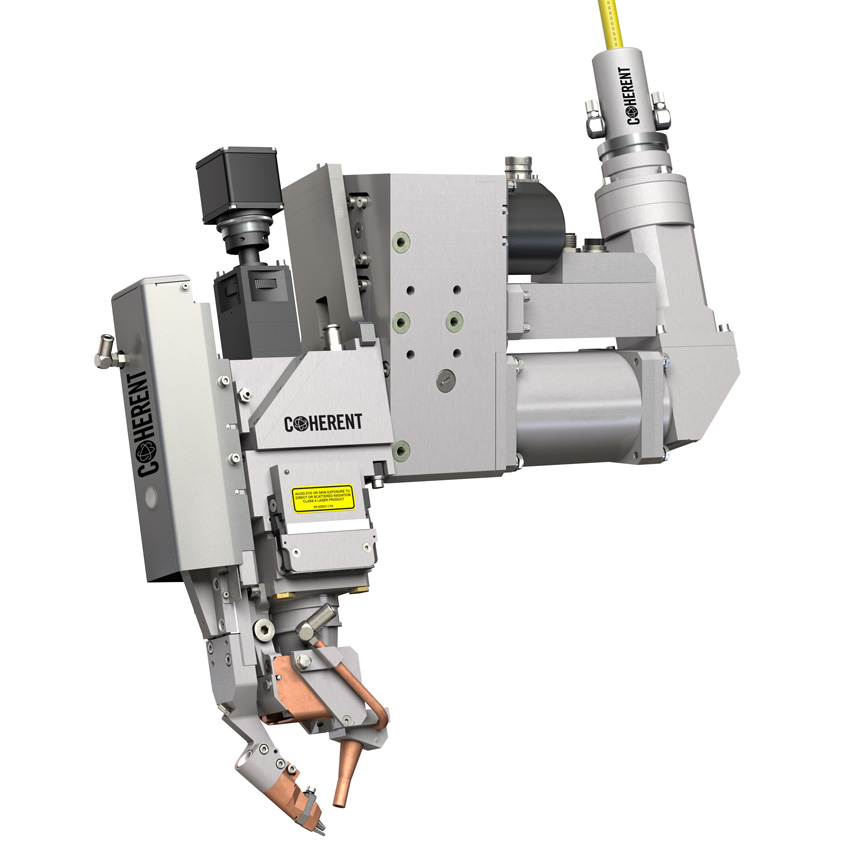

用于焊丝钎焊和焊接的触觉焊缝跟踪加工头,可提供优质的焊接结果和卓越的可靠性。 |

非常适合白车身焊接和钎焊任务,包括行李箱盖、车顶和密封管道。 |

模块化光学器件提供多种光斑尺寸选项,并维持输入强度分布。 |

提供可编程力控制以及放大倍率和散焦。 |

借助易于配置的工具,即使在形状复杂的零件上,也可以始终获得高质量的铜焊和焊接接头。 |

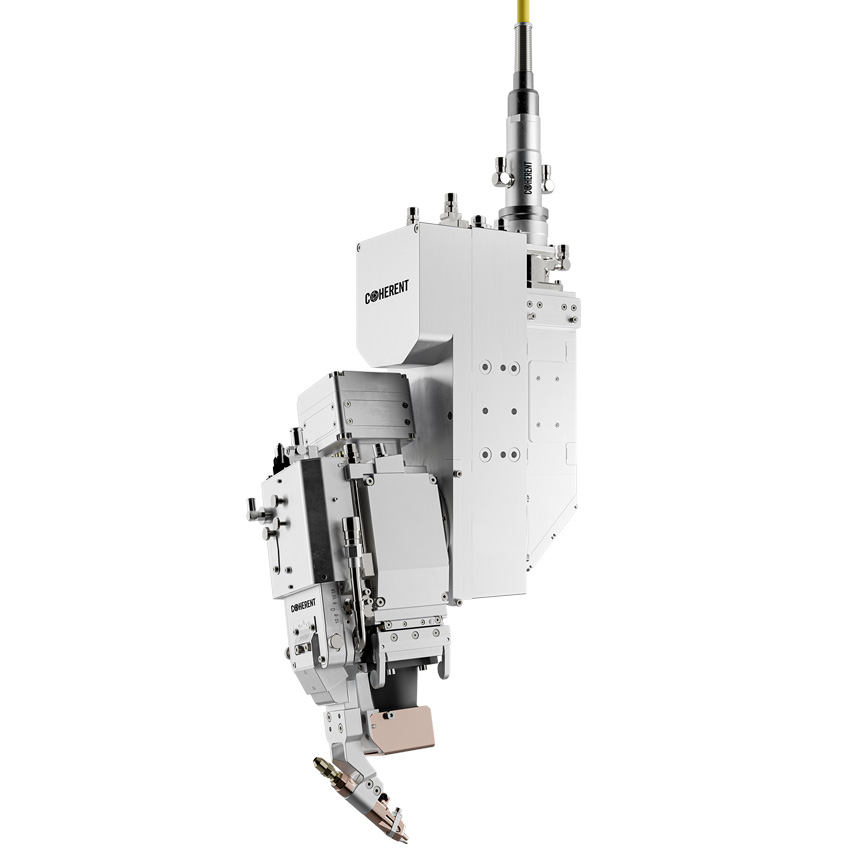

功率强大的灵活系统,适用于汽车铜焊应用以及白车身和电动汽车生产中的各种丝焊任务。 |

将先进的传感器和伺服技术相结合,提供精确的力控制,并采用支持快速设置的界面。 |

HIGHtactile 可与各种光纤传输激光器、焊丝类型和工艺监控系统配合使用。 |

切割头和配件

一系列高速光纤激光切割产品,可加工厚度达 50 毫米的金属板材(如低碳钢、不锈钢、黄铜、铜和铝)。 |

与标准和光束整形光纤激光器兼容,可在汽车、能源、运输、白色家电和其他制造领域实现可靠的零件切割。 |

独特的光学设计,具有大焦距和变焦范围,可在各种材料和厚度上实现出色的切割性能。 |

支持超高功率(高达 30 kW CW)运行。 |

SmartCut+ 适用于 Coherent PowerLine FL 激光器的切割头,可在金属中产生复杂的微结构,减少了锥度,提高了速度。 |

消费电子产品、医疗产品和钟表制造中的精密零件制造。

|

图型包括传统的摆动,以及螺旋、椭圆和其他复杂形状。特别适用于零件生产线的飞行加工。

|

提供能够媲美其他更昂贵激光器的效果。

|

激光划线加工头包括光束传输光学器件、气体处理喷嘴和控制软件。 |

用于在液压裂化前对内燃机连杆进行划线。

|

每个零件的划线用时为一秒。

|

可用于连杆划线的全集成激光解决方案。

|

用于光纤激光焊接、切割、钻孔和划线应用的准直器、工艺光学元件和配件的模块化系统。 |

灵活、模块化、高精度的激光加工头,可轻松配置,为各种精密制造任务提供出色的加工效果。 |

适用于功率高达 3 kW 的激光器。 |

提供配置选项红外指示光和过程观察相机。 |

其他加工头

PH50DL 变焦光学器件 可将高功率半导体激光输出转换为均匀的平顶型矩形 2D 聚焦光斑,其长度和宽度可在软件控制下即时独立调节。 |

应用包括热处理、硬化、熔覆、激光辅助粘合、μLED 粘合和带铺叠。 |

可以动态更改光斑尺寸以优化每个应用的激光回火工艺。 |

易于集成的工艺监控选项,包括高温计控制和改进的质量。 |

更换用激光喷嘴和配件

从广泛的产品中进行选择。 |

快速交付高质量的更换用喷嘴和配件。 |

与各大制造商的加工头兼容。 |

我们库存中拥有数以千计的更换用激光喷嘴,全部按照设备制造商规格制造。 |

视频聚焦

异质材料的可靠激光焊接

SmartWeld+ 可实现热敏材料和异种材料(例如铜与铝或钢)的精密激光焊接。 还可以在焊接这些材料时减少飞溅和裂纹,并降低孔隙率。 借助这种技术,在以前难以采用激光加工的应用,也能受益于光纤激光器的经济性、便利性和可靠性。

精选博客

推出 SmartSense+ 工艺监控配件

全新 SmartSense+ 工艺监控解决方案改进了许多精密激光材料加工任务的成果,并降低了成本。

准备好开始了吗?

分享您的联系信息,我们的专家会与您联系。