WHITE PAPER

Fiber Solutions for OCT Imaging

Coherent is among the world’s leading providers of non-telecom optical fibers and fiber optic assemblies. Our standard and custom fibers for use by OEMs in optical coherence tomography (OCT) offer a superior combination of features and advantages for this demanding imaging field.

Key Features and Advantages

- High bandwidth for high image resolution

- Precise dispersion control for image fidelity

- Single and double-clad options

- Very low loss for highest signal to noise ratio

- Acrylate and biocompatible coatings

- Tight dimensional control simplifies integration

OCT in Brief

OCT is a type of white light interferometry where broadband light is directed into tissue from a fiber probe. The (backscattered) returned intensity is mixed with light from a reference back reflection and sensed with a photodetector. An interference signal is generated only when the two path lengths are the same. By sweeping the reference arm length (or by an equivalent Fourier transform) the OCT system is thus able to assign back scattered reflections from the tissue to the precise Z depth. This line of data is called an A-scan. An XZ image slice is then built up by scanning the probe laterally along the X axis. And a full 3D image is acquired by combining many slices by scanning along the Y axis.

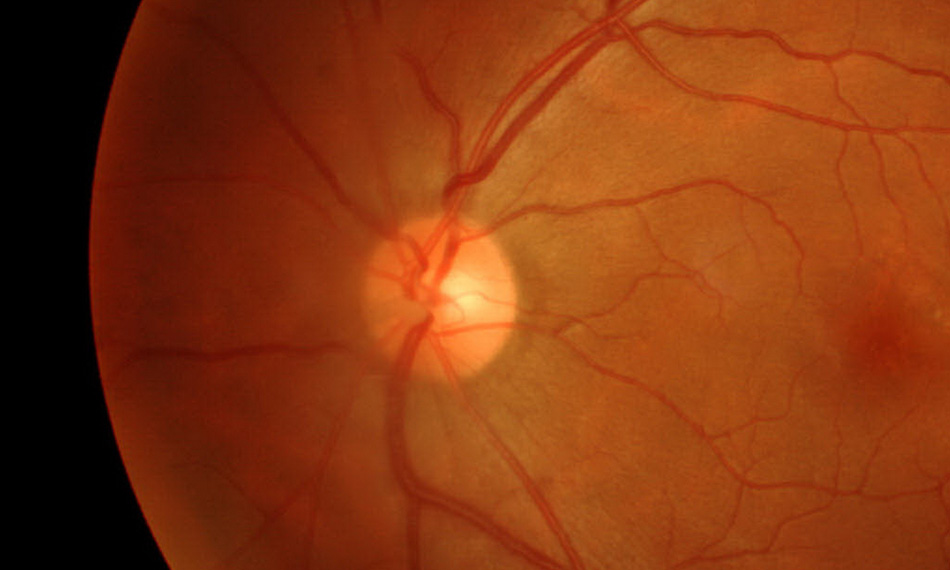

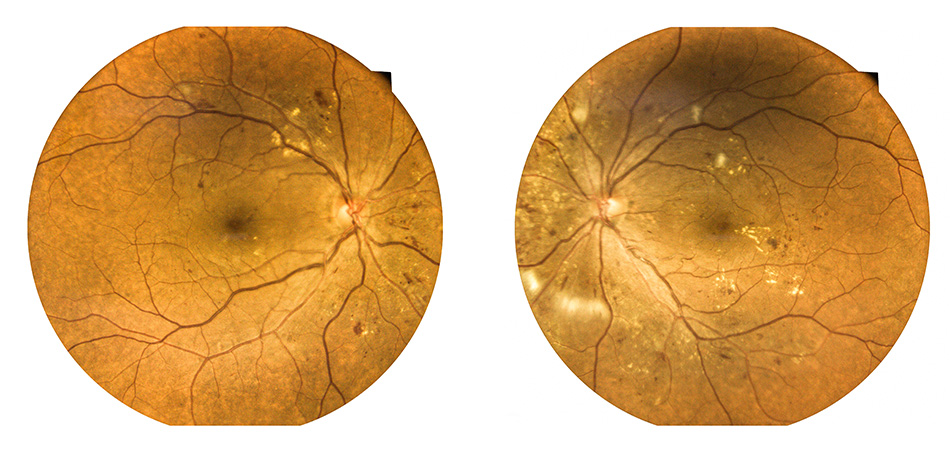

OCT is thus a 3D imaging that provides higher resolution than ultrasound imaging, but lower resolution than confocal microscopy. As a result, its most common application is for detailed tissue imaging as in ophthalmology, e.g., to monitor glaucoma progression.

Figure 1: Ophthalmology is a key application for OCT imaging.

High Bandwidth

Some OCT systems use a wavelength-swept source, but it’s more common to use a broadband source such as a super-continuum. A wide spectral range is needed because the axial (A-scan) image resolution is inversely dependent on the spectral range. So in both broadband and swept formats, it is vitally important to use fibers that don’t truncate the wide bandwidth of the OCT light source. Coherent draws our OCT fibers from high-purity glasses specifically chosen for their broadband (and flat) transmission characteristics. This includes fibers with shorter wavelengths around 780 nm that is a great match for ophthalmology. We also make fibers centered at 1060 nm, as well as long wavelength fibers centered at 1310 nm which is increasingly popular for deeper imaging because light scatter is minimized in this wavelength region.

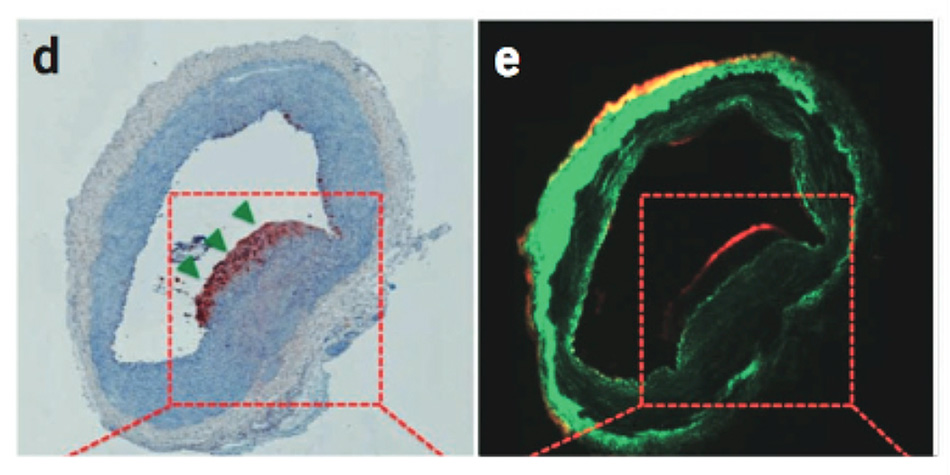

Figure 2: High resolution OCT images inside a blood vessel. Courtesy of Harvard University Wellman Center.

Precise Dispersion Control

OCT depends on comparing light coming back from the tissue with light that has passed along an identical path length through the reference fiber. But all glass fibers exhibit some dispersion where the refractive index, and hence the effective path length, varies with wavelength. This dispersion is accommodated in the OCT signal processing software. But this wavelength-dependent-correction only works correctly if the dispersion is the same in both the sensing and reference fibers. And it must stay the same when either of these fibers is replaced for any reason, otherwise image processing errors and diminished axial resolution may occur. Dispersion is really an issue of material quality and Coherent uses only glass preforms selected for their superior and highly consistent dispersion specifications from world-leading suppliers.

Single- and Double-Clad Fibers

Coherent offers both single- and dual-clad fibers for OCT use. Why? Early OCT systems used a probe incorporating two sampling fibers. A single-mode fiber was used for the forward path and a second fiber handled the returned light reflected back from the tissue. The return fiber optimally uses a larger core to increase the light collection and coupling efficiency. Later designs often use just one fiber for both forward and return paths. But to achieve similar single-to-noise and image resolution with the older two fiber setup, this one fiber format requires a dual clad fiber for optimized transmission of both the excitation and back-reflected light. Coherent supports both OCT instrument types as well as instruments that combine OCT and spectroscopy with a full range of both single and dual-clad fibers.

Very Low Loss Transmission

Maximizing signal-to-noise is important in OCT because the returned light intensity can be very low. So it is crucial to use fiber with low transmission loss to optimize the signal intensity and thereby maximize image quality and minimize image acquisition times. We provide fibers with the lowest possible transmission loss because we start with high quality glass characterized by low absorption and low scatter. Some loss also inevitably happens at splices, connectors, etc. Coherent has decades of experience supplying fiber and fiber assemblies in a wide range of formats to demanding industrial and medical applications. We understand how to comprehensively optimize all the processes involved in cleaving, splicing, aligning, connectorizing, etc. So whether you’re using bare fiber or a completely integrated module from Coherent, you can be sure it will always provide the lowest transmission loss. Coherent offers fiber with low attenuation loss, as low as <1 dB/km.

Acrylate and Biocompatible Coatings

Coherent optical fibers for OCT and other medical applications are offered with several different outer coating options. These can be selected to protect the fiber by maximizing abrasion resistance, to support repeated sterilization (autoclaving) cycles, and/or to minimize any risk of irritation and inflammation in intra-corporal applications. Specific available coatings include acrylate and polyimide. Tefzel is also a popular choice we offer for medical applications because this biocompatible thermoplastic provides an attractive combination of mechanical toughness and chemical resistance.

Other Advantages

Coherent fibers for medical use offer a number of other practical advantages, which can be critical in some applications. We draw, coat, and test these fibers with extremely tight dimensional control. This simplifies their use in precision catheter assemblies. Similarly, the fibers are characterized by superior core/clad concentricity which minimizes the risk of splice or connector induced artifacts. We also use glass and other materials that can be optionally sterilized using radiation as an alternative to autoclaving for example.

Vertical Integration and Experience

The optical fiber is a critical OEM component of an OCT system. As such, the choice of fiber manufacturer is just as important as the fiber itself. Coherent brings a number of advantages which makes us an ideal partner for any OCT system builder. First and foremost, we thoroughly understand the medical fiber component business and follow FDA good manufacturing practices throughout: e.g., we maintain Device History records and retain this data for the appropriate time. Coherent is also a vertically integrated provider able to support you all the way from prototypes through volume production. Plus we have extensive expertise in the fabrication of complete fiber optic assemblies in our ISO 13485 and low bio-burden compliant factory. Instead of purchasing fiber and sending it out for custom connectors or tips, let Coherent deliver to you the ideal fiber optic assembly, fully tested and ready for simple integration into your system.