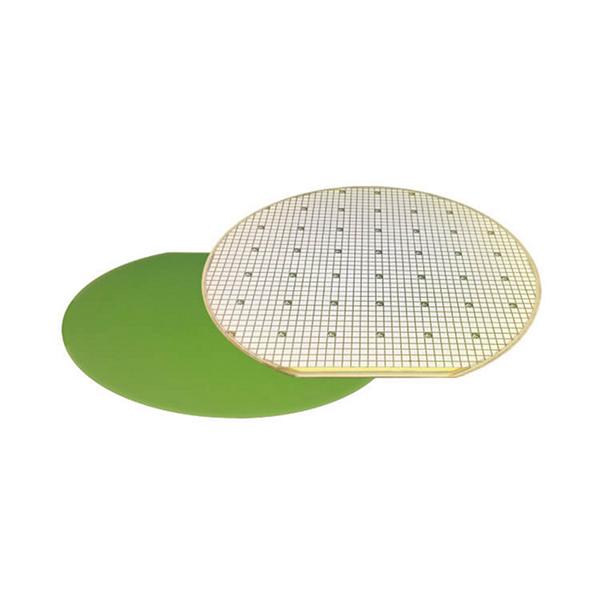

SiC Substrates & Epitaxy

SiC Epitaxy

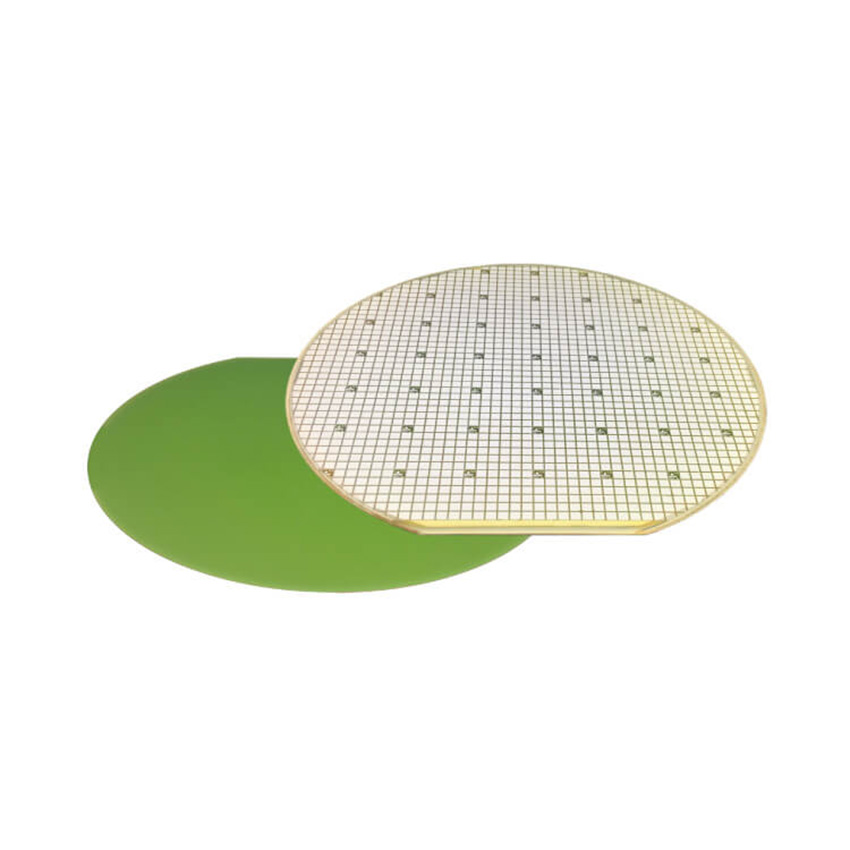

Accelerate time-to-market, reduce costs, and improve device performance by building on high-performance SiC epitaxial wafers from Coherent in up to 200 mm diameter.

Coherent offers a total SiC materials solution with options for thick epilayers with or without buffer, low-doped layers, multilayer structures, p-n junctions, embedded/buried structures and contact layers, and more. We support R&D to volume production.

SiC Epitaxy Capabilities Highlights

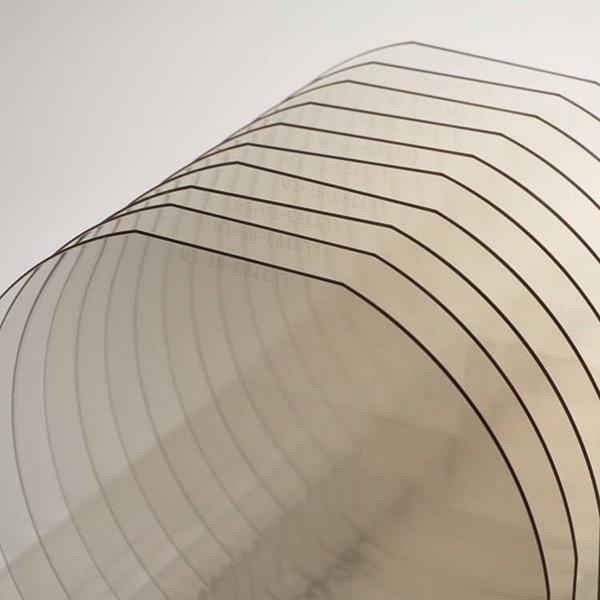

State-of-the-art SiC epitaxy technology

Record-low defect density through efficient buffer-layer technology

Prevents nucleation of crystalline defects at growth start

BPD to TED conversion rate >99.8% → 1 BPD per cm2

Enables bipolar SiC device technology

Best-in-class layer homogeneity with LPE PE106

Adjustable lateral gas flows

High growth rate of 40 µm/h using TCS as a silicon precursor

Thick layer growth of 150 µm and more

Low doping concentrations of 1×1014/cm3

Enables >15 kV SiC device technology