Lasers

ARM Fiber Laser

Go beyond what's possible with advanced fiber laser technology for effectively welding delicate or heat-sensitive materials, dissimilar materials, cast alumninum and even copper.

Coherent Adjustable Ring Mode (ARM) fiber lasers utilize a unique center/ring beam. Totally independent power and modulation control of these two beam components enables highly precise energy delivery for enhanced capabilities and improved results. New model with independently controlled center beam and two separate coaxial ring beams.

ARM Fiber Laser Overview

Get the power and control you need for speed, process consistency, and part quality with a wide selection of output powers and beam brightness values.

|

Fiber Management |

Beam Management |

Output Power (kW) |

Center Beam |

Benefit |

ARM FL |

Detachable Fiber |

FFC or FFS |

2 - 10 |

multi-mode |

Fiber switches and couplers for flexible production |

ARM FL D |

Detachable Fiber |

FFC or FFS |

6 - 20 |

multi-mode |

High throughput and deeper welds |

ARM FL Compact |

Spliced Fiber |

none |

2 - 10 |

single-mode or multi-mode |

High beam quality and compact housing |

ARM FL 4000CSM |

Spliced Fiber |

none |

4 |

single-mode |

Excellent beam quality for demanding applications |

Related Products

Featured Blog

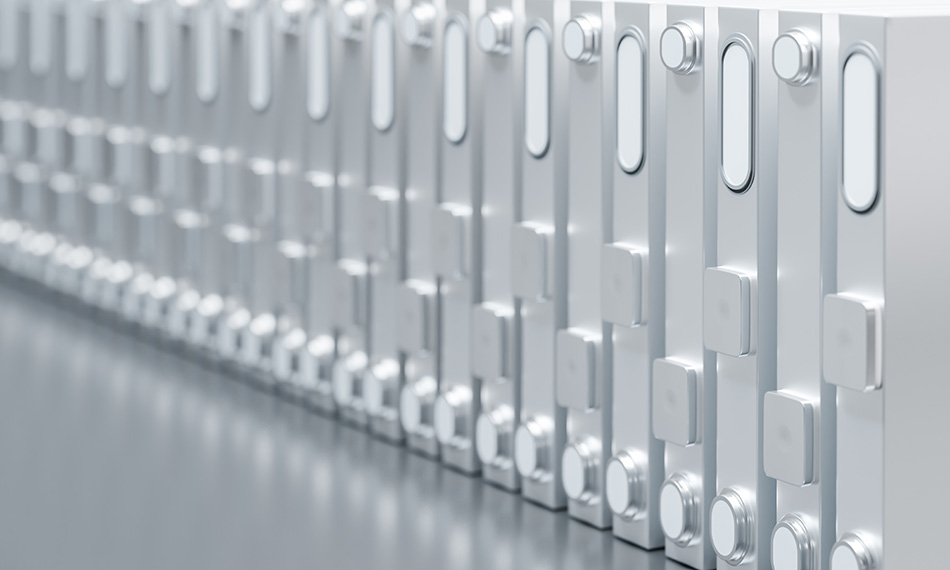

Coherent ARM Fiber Lasers Seal the Deal for Battery Manufacturers

Discover how Coherent ARM fiber lasers deliver the precise control needed for welding high-strength steel and even multi-layer composites.