SOLUTION BRIEF

Welding of Dissimilar Materials: Aluminum Foil Busbar to Copper Bar

Introduction

Battery system manufacturers require cost-effective, fast, and reliable welding methods for thin aluminum and copper foil applications. Non-contact laser welding offers an attractive option, but has not been usable in the past with foil thicknesses below 200 µm. This was because existing fiber laser sources could not deliver their power with the necessary spatial distribution. Specifically, a high-power fiber laser produced damage on the top foil sheet, while low-power fiber lasers didn’t achieve adequate weld penetration. The Adjustable Ring Mode (ARM) fiber laser with a single-mode center beam overcomes these limitations.

Process

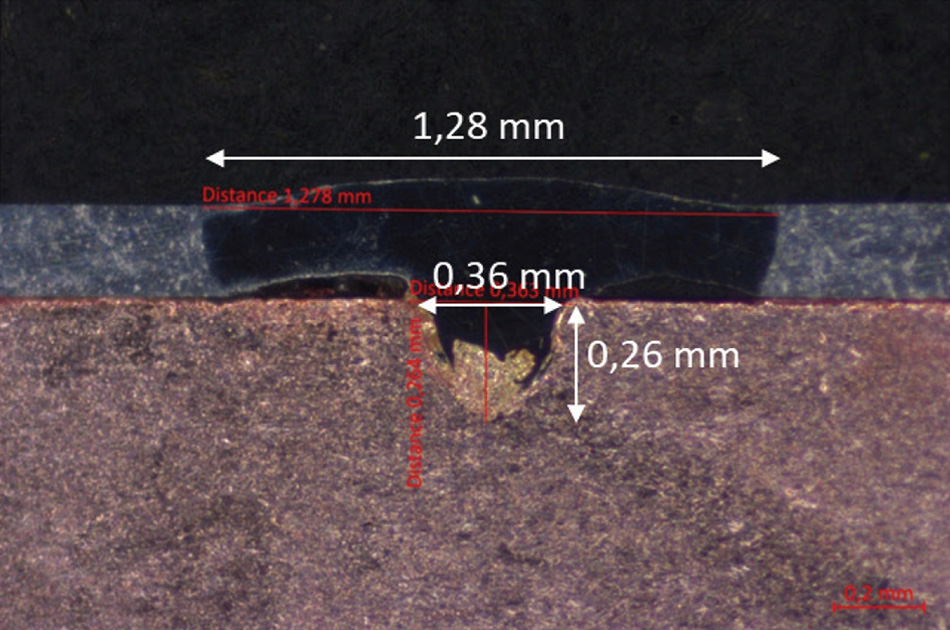

A common task in battery module production is connecting multiple batteries together in electrical series by overlap welding a thin aluminum busbar to thicker copper bar. Tests were performed on welding a 0.2 mm thick aluminum sheet (on top) to a 1.5 mm thick copper bar (on bottom). The HighLight FL4000CSM-ARM source was used, with a 25 µm/170 µm (center beam/ring beam) process fiber, and remote welding scanner optics that produced a 3x magnification of the beam at the work surface. Center beam power was 500-800 W, and ring power was 1000-1200 W. Laser power was applied for 0.18-0.32 seconds. The power in the center and ring beams was independently controlled.

Results

A high-quality, full-penetration weld was achieved, without damage to the thin aluminum foil (see figure 2). The process produced no spatter and did not require the use of filler wire. The reason for these positive results is that the ARM laser stabilizes the keyhole welding depth with the ring beam. The single-mode center beam, with its high brightness (high energy density but low total energy), performs the actual welding without damaging the material by introducing in too much heat. Finally, the independently controlled ramp down of the ring power allows the material to cool in a controlled manner, thus minimizing weld pool turbulence and eliminating spatter.

Application Field

Laser welding of thin foils and heat-sensitive materials for battery and e-mobility applications. This includes copper foil stack and foil-to-tab welding in the battery industry, and aluminum sheet-to-copper bar welding.

Figure 1: Adjustable Ring Mode (ARM) - independently controllable ring and center beam

Figure 2: Cross-sections of copper-aluminum weld.