The Smart Way to Manufacture Medical Devices

Coherent Laser FrameWork is a unified software platform for controlling laser machines with an integrated suite of process monitoring and control tools – delivering a boost in manufacturing productivity.

July 5, 2022 by Coherent

Medical device makers today are caught in a “perfect storm” of manufacturing challenges. Their products are getting more complex and precise. Of course, since people’s health is riding on these devices, there’s no room for manufacturing errors. Plus, in nearly every country, regulatory agencies have increased their requirements for product traceability and conformance to standards. To top it off, an increasingly globalized market creates ever more competition for device makers. This often means all of these objectives must be achieved without increasing costs.

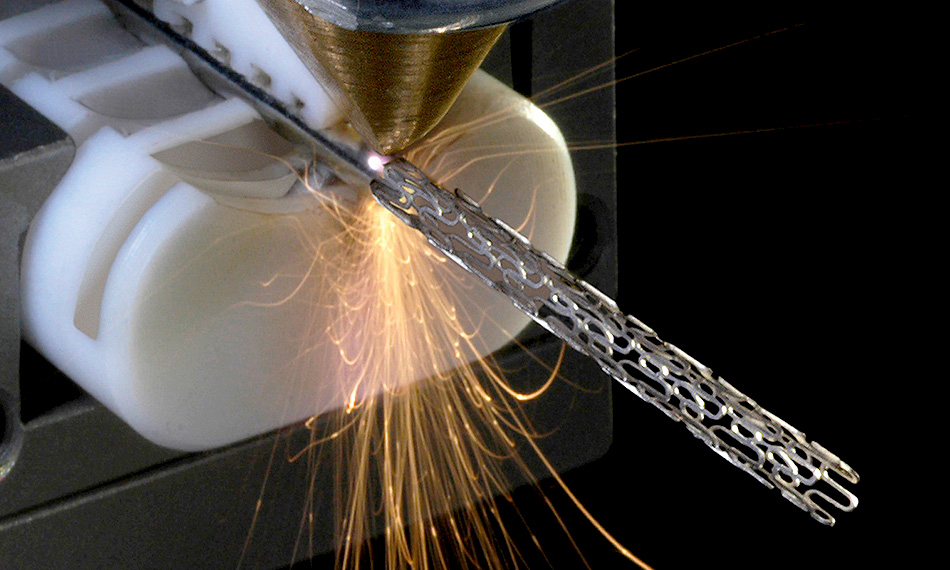

The good news is technology offers means for manufacturers to meet these goals, and lasers often play a key role. The reason lasers are so important is simple. No other technology matches the quality of results they deliver for many marking, cutting, welding, and other materials processing tasks. Lasers offer an unrivaled ability to process materials with higher precision, less part distortion or damage, minimal heat-affected zone, and better cosmetics. And, for the higher-value, smaller, and more physically delicate parts often encountered in medical products manufacturing, this set of benefits is particularly valuable.

Today, when lasers are combined with the latest advances in software, microprocessors, and sensors, the result is a new generation of machine tools that are simpler to use, more reliable, and easier to maintain. All of this reduces cost-of-ownership.

Coherent has introduced a series of laser marking, welding, and cutting systems that represent this convergence of technologies — and an essential element of our solutions is Coherent Laser FrameWork, which is a unified software platform that manages all system functions (both operational and diagnostic), enables communication with other systems, and is easily extensible.

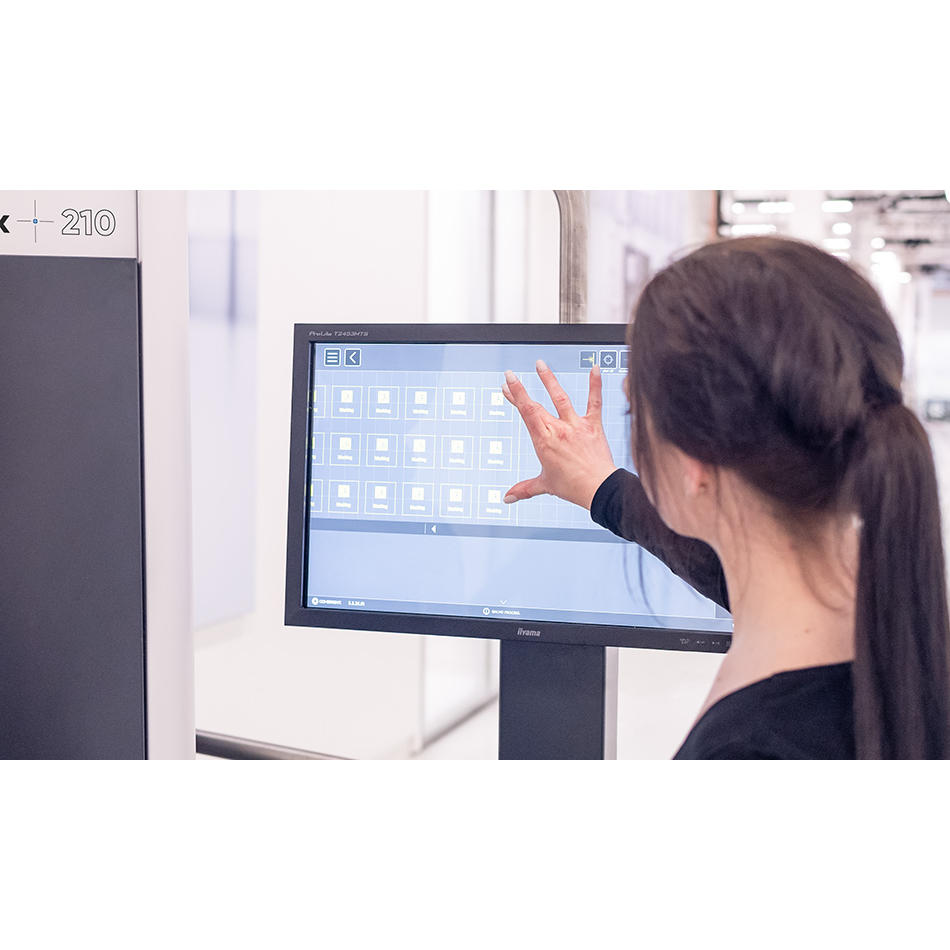

A better UX

The advantage of controlling all laser system functions in a single, intuitive user experience (UX) is enhanced productivity. With Coherent Laser FrameWork, for example, an operator doesn’t need to run different software packages, master various UIs, and worry about porting data between unrelated software modules to integrate a laser system into the production process.

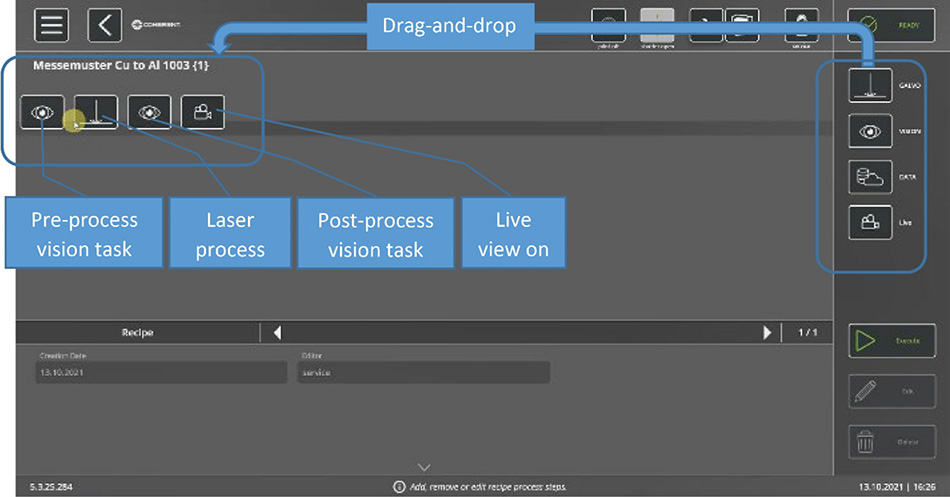

Laser FrameWork specifically enhances ease of use by employing a simple visual process design tool built on a concept called the “recipe.” The recipe is a sequence of process steps necessary to perform a specific laser application. Process steps include every action the system can accomplish – operating the laser, vision tasks, data exchange, system diagnostics, process monitoring, part motion and handling, and more. Finally, a “job” includes a recipe and additional data for how it is to be performed. For example, the number of times to execute the recipe, or instructions for where and when to obtain process input variables.

Within Laser FrameWork, a recipe is created through a series of simple drag-and-drop operations. Each step in the process is placed on the timeline in the desired order. Most of these process steps will have been defined in advance. The functionality for creating a new process step or modifying an existing one is similarly simple; all the required parameters for a function are provided in a setup menu, and the user fills in values or selects from predefined options.

Lowering costs with better process and system monitoring

Laser FrameWork also integrates the ability to use various embedded and add-on Laser FrameWork Accessories. These system process and monitoring tools lower costs, improve quality, reduce errors, and eliminate unplanned downtime.

One Laser FrameWork accessory is machine vision (called PartVision), which can eliminate the need for specialized tooling, thus cutting costs. It can also compensate for the way parts have been placed in the working chamber; this speeds workflow and reduces errors.

In a marking application, for instance, vision can identify the position (in three dimensions) and orientation of parts in a tray, and then automatically adjust machine operation accordingly. A number of parts can be laser marked, with the system automatically finding the correct location for the mark on each part. It can adjust the pattern so that the final mark is properly oriented and not distorted, even if the part surface isn’t perpendicular to the laser beam.

Vision can also be employed after processing for part inspection, process validation, and documentation purposes. And within Laser FrameWork, setting up vision tasks, such as identifying a particular feature on a part and using that as point of reference, are easily accomplished and essentially all menu-driven.

Similarly, real-time, in-line monitoring (which we call Coherent SmartSense+) can provide early detection of laser process variations, allowing system operation to be corrected or stopped before bad parts are produced. Again, this cuts costs, and the ability to implement it is completely contained within Laser FrameWork.

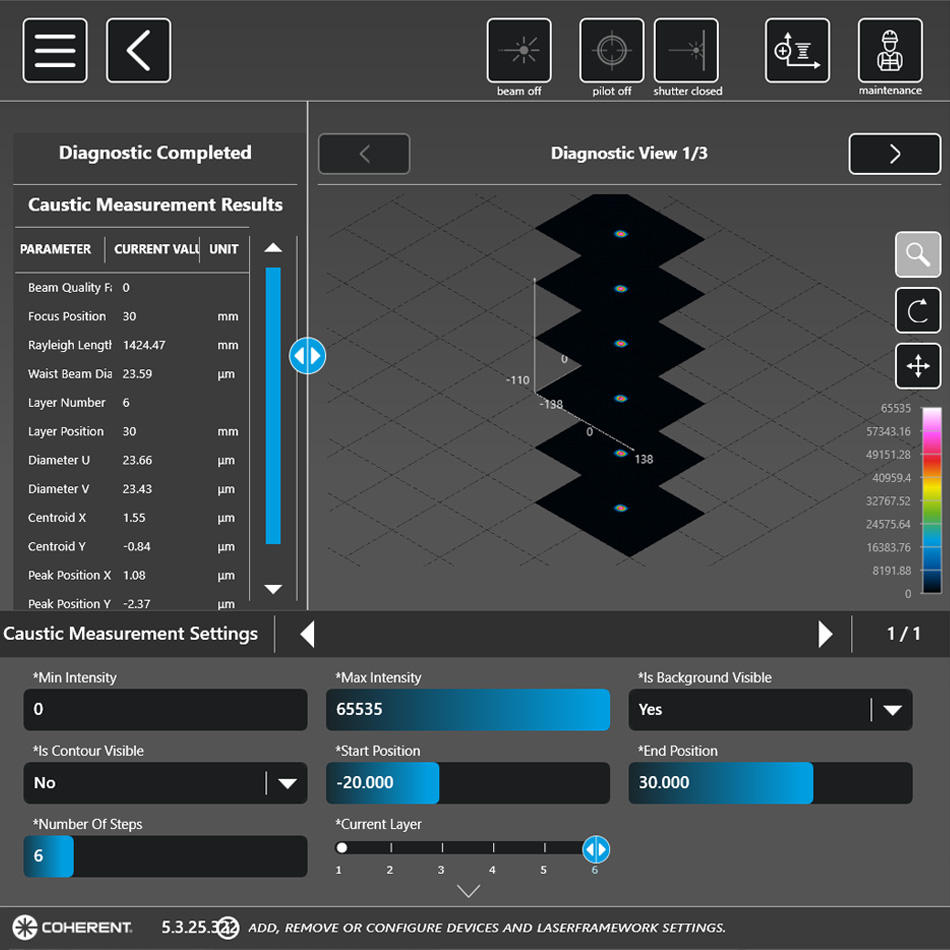

Our Coherent BeamInspect embedded beam diagnostic system measures machine performance. In this case, the exact characteristics of the focused laser spot itself. Because it’s easy to include beam diagnostics within a recipe or job, it can be performed frequently. This reduces scrap, helps avoid downtime, and allows preventive maintenance to be scheduled when it’s most convenient

Improving connectivity and automation

Increasingly, production equipment doesn’t stand alone. Laser machines must often communicate with other systems in a manufacturing environment. This might include Enterprise Resource Planning (ERP) systems, Manufacturing Execution Systems (MES), or other host computers. In a marking application, for example, the laser system might have to obtain individualized product data (such as serial numbers or UDIs) from an external system. Similarly, many other machine functions and operations might be triggered by signals from another source.

Once again, this functionality is easily implemented through Laser FrameWork. The software provides menus that enable all the major TCP/IP communications protocols to be accessed and configured.

The smart framework for powerful productivity

Staying competitive in medical device manufacturing today is all about productivity. Getting more from your operation – higher throughput, reduced downtime, improved quality, and fewer errors. Lasers offer all that – and now Laser FrameWork makes them easier to use, simpler to integrate, and more reliable than ever. And that’s productivity.

Learn more about Coherent Laser Framework.