Flow Cytometry: OEM Laser Engines Deliver Multiple Benefits

Permanently aligned laser engines based on miniaturized components lower costs, simplify assembly, and deliver better CV for next-generation flow cytometers.

July 26, 2022 by Coherent

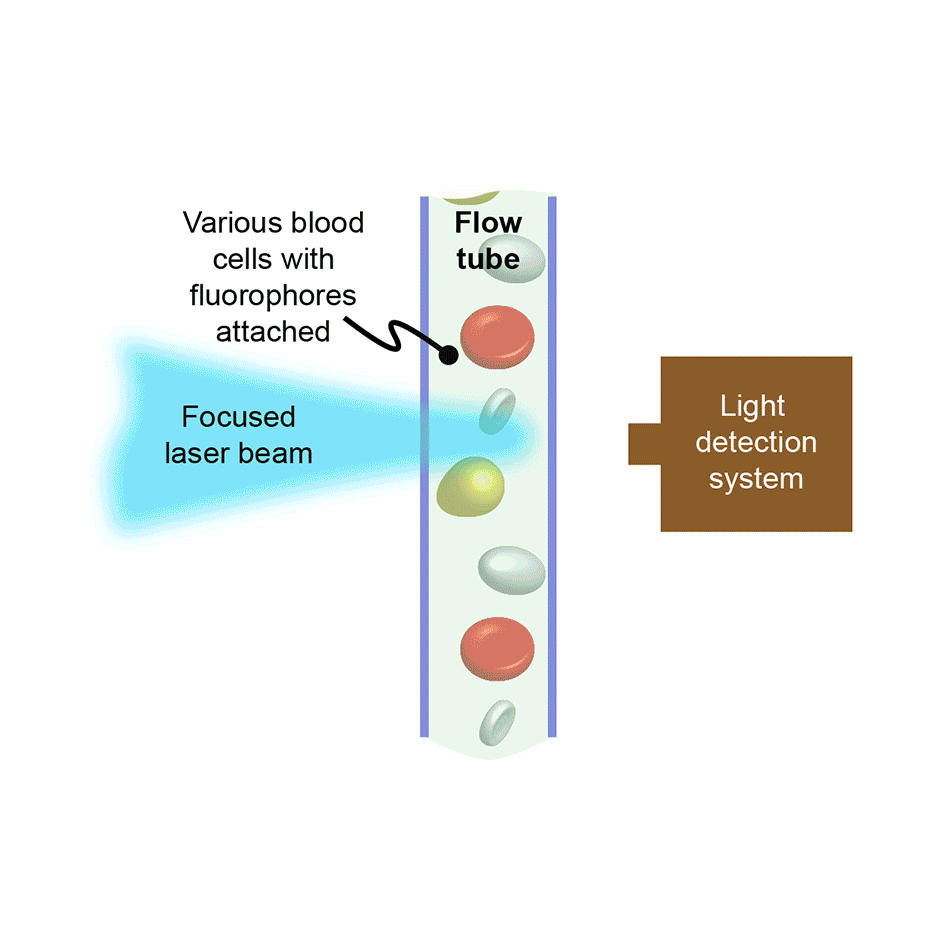

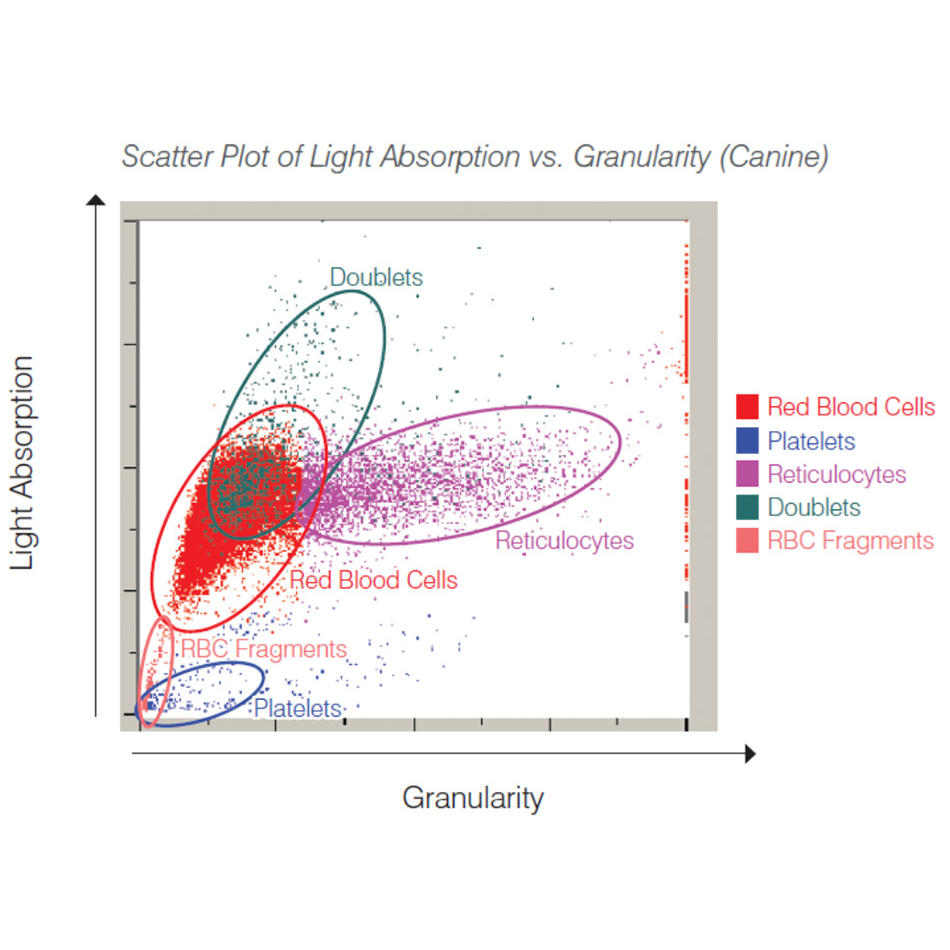

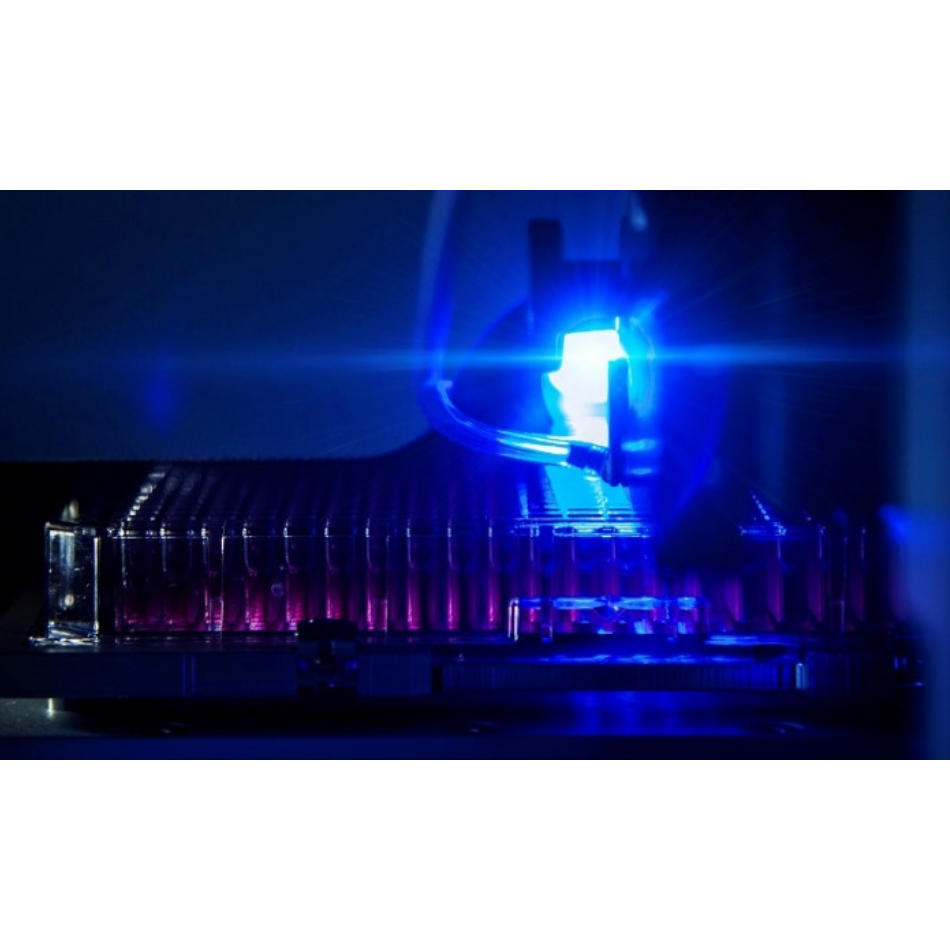

Flow cytometry, and particularly multi-parameter flow cytometry, is one of the most challenging instrumentation applications for lasers anywhere. That’s because multiple laser beams need to be integrated, shaped, aligned, and focused, all within a few microns precision and repeatability.

The challenge becomes greater as flow cytometer builders meet market pressures to reduce the cost and size of their instruments while also maximizing performance and field reliability.

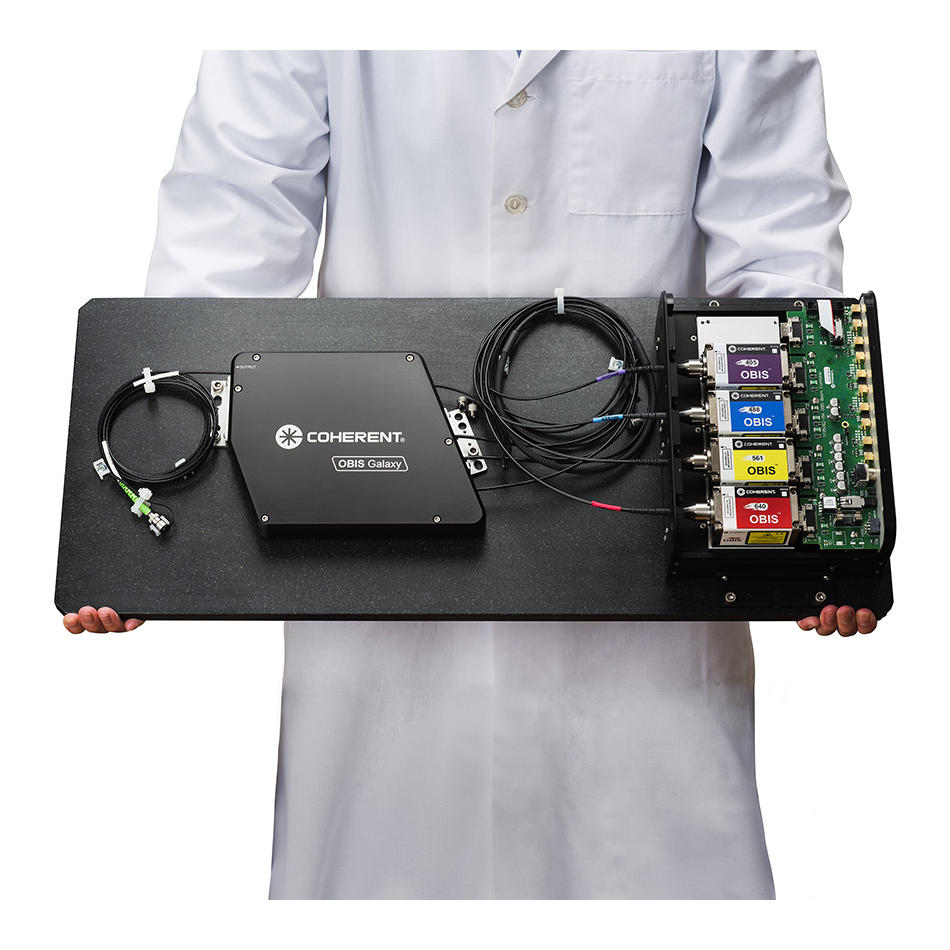

Laser engines – integrated modules incorporating lasers, electronics, and optomechanics – are proving to be key elements that simultaneously address all these factors. The latest development in laser engines includes the revolutionary use of miniaturized, permanently aligned optics in what are now 3rd generation OEM laser engines.

Let’s look at why this is a game-changing advance.

So just what is a 3rd generation laser engine?

The first generation of laser engines provided multiple laser wavelengths for the first time. But they were basically a box or breadboard incorporating multiple individual stand-alone fully packaged lasers. This meant inevitable redundancy – multiple PCBAs and interfaces, and unnecessary enclosures. And the instrument builder had to provide and then align large generic adjustable optics and mounts to steer, shape, and focus the beams.

The second generation featured laser miniaturization. They used multiple laser “cores” driven by a single PCBA, with one interface, one power supply, and just one enclosure. This also meant these CellX engines could be smaller. And the overall size was no longer limited by the lasers, but by the need for conventional optics and mounts which allowed instrument builders to adjust and optimize all the individual beams.

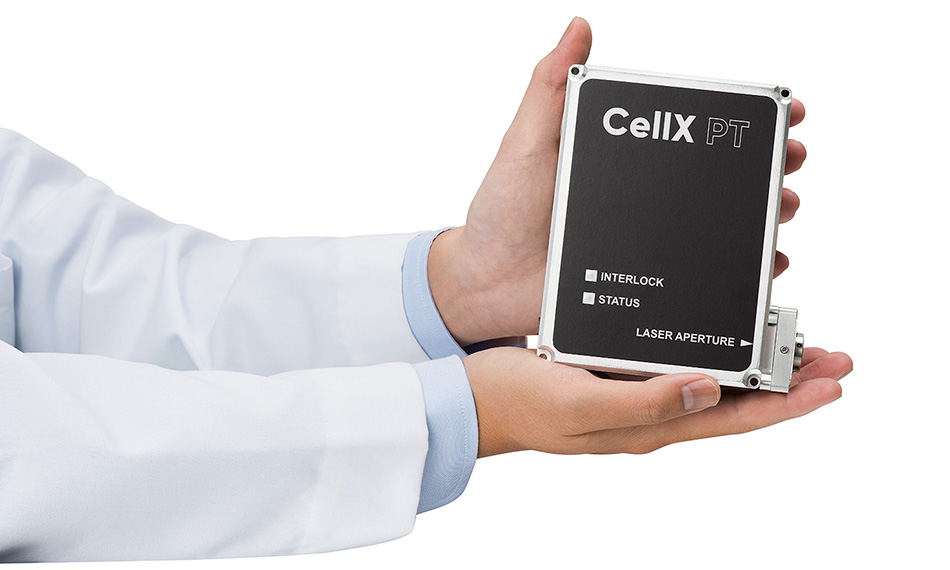

The new third-generation engines - called CellX PT - use miniaturized optomechanics called PermaTrack™ instead of conventional optics and adjustable mounts.

Based on technology long proven for demanding intra-cavity use in Coherent lasers, small diameter optics are aligned during manufacture and permanently fixed in place.

This not only lowers the overall size of these OEM engines – by about 50% – it also lowers costs and increases stability and long-term reliability. That’s because all the lasers and optics are now contained within a hermetically sealed environment which also includes getters to maintain pristine conditions. And since PermaTrack technology is based on automated (i.e., robotic) assembly and alignment, it also increases unit-to-unit consistency.

Yes, but what about accommodating variations and tolerances in instruments?

Coherent CellX PT laser engines are currently available factory-configured with a choice of four different visible wavelengths. These are projected as a ladder of line foci to optimally match standard flow cell geometries. The power, line shape, and beam profile are all specified and guaranteed at the flow cell, eliminating design uncertainties.

Of course, instruments always include inevitable physical tolerances. CellX PT fully accommodates these variations using a final focusing lens that is flexure mounted outside the sealed cavity. This is user-adjusted to optimize the position of the ladder of beams in all three axes X, Y, and Z.

And instruments also vary in their design and optical requirements. CellX PT is an OEM solution using a common platform that can be readily factory configured to specific volume requirements in terms of wavelengths, power, focus stripe size, spacing, and sequence. This results in fast delivery to support every stage of the instrument cycle, from prototypes through volume production. A CellX PT lifetime is typically more than 5,000 hours. And the adjustable focal position means the CellX PT unit can be easily replaced in the field. The unit is then factory serviceable by Coherent, an option that further increases its value.

Where do laser engines go from here?

Coherent has a 50-plus-year history of innovation so you can bet we will continue to develop laser engines. In the future, you can expect to see more wavelengths and output beam shapes to match developments not just in flow cytometry, but other instrumentation fields too. Anywhere there is a multi-faceted benefit for OEMs to specify and source a complete and integrated photonic solution, not just a laser.

Discover more about Coherent lasers and laser engines for flow cytometry.