SOLUTION BRIEF

Marking Plastic and Glass Products and Packaging with Ultraviolet Lasers

Challenge

Manufacturers of medical disposables and packaging, pharmaceutical containers, and a host of plastic and glass consumer products all have a critical need to permanently mark these products, e.g., for tracking, anti-counterfeit, branding, or functional purposes such as graduation marks. Labels can be damaged or removed, inks can contaminate, and infrared lasers will cause charring and other unwanted thermal effects.

Solutions

Ultraviolet lasers are ideal for most of these marking tasks since the high-energy photons from these lasers directly break the molecular bonds in plastic polymers. This can be used to cause a photochemical transformation that changes the color of the plastic, without removing material or causing any thermal damage to the surface.

The most common photochemical transformation is to bleach a colored material and leave a pale mark. Some materials are designed to produce other types of color change. For example, ultraviolet lasers can create dark, high-contrast marks on nylon and polyurethane that are white due to titanium dioxide doping, as in nylon circuit breakers for residential use. Ultraviolet lasers can also mark transparent and coated, colored plastics as well as performing cold engraving of coated and uncoated glass. In pharmaceuticals, UV laser marking is also well-suited to marking gel capsules and blister packages, and for creating QR codes on bottle caps.

Coherent is a world leader in pulsed ultraviolet lasers for marking and other industrial applications. Our decades of experience in ultraviolet applications deliver lasers with the highest reliability and longest lifetime, e.g., the PowerLine E 8 QT.

Benefits

Ultraviolet laser marking meets the broad need for marking plastic components and packages in a cold process, e.g., without creating any HAZ or other thermal damage. Coherent laser markers provide you with proven ultraviolet marking solutions from an experienced vendor who can also simplify any mandated certification processes.

Application Field

Marking medical plastics, packaging, catheters, inhalation masks, syringes, pharmaceutical bottles, and related products.

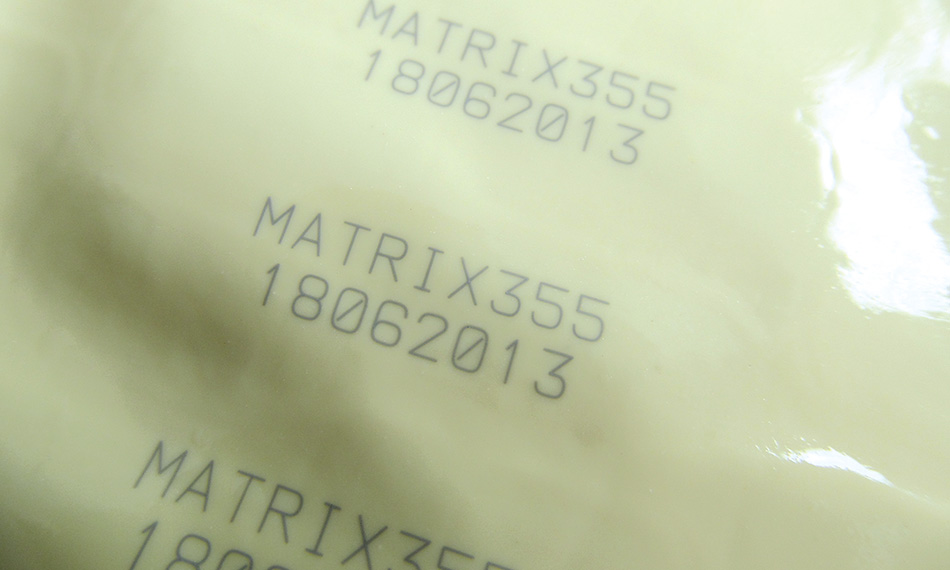

Figure 4. UV laser marking is ideal for direct marking of many clear plastic products.