CUSTOMER SUCCESS STORY

IPS: Optical Isolators Improve Laser Reliability

The Challenge

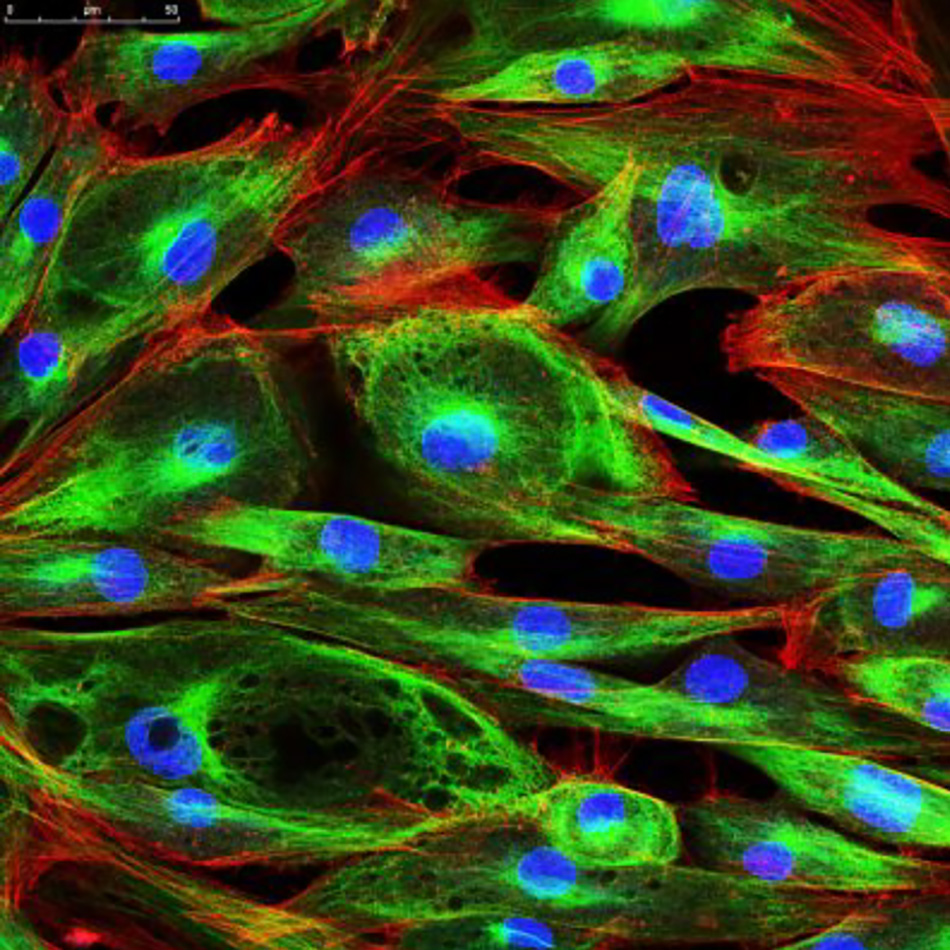

Raman spectroscopy and imaging are powerful methods for interrogating samples in research and industrial settings, for everything from quality control (QC) to identifying polymorphs, to label-free imaging of live cells, as well as chemical process monitoring applications. That’s because the Raman effect produces spectrally resolved chemical-fingerprint data similar to Fourier Transform Infrared (FTIR) but uses light at visible and near-IR wavelengths that can be transmitted through glass fibers, lenses, and into water-based samples. The tools required to accurately measure a Raman spectrum completely changed with the convergence of three technologies that enabled compact self-contained spectrometers and microscopes. The three technologies are compact high-power narrow-linewidth semiconductor and solid-state lasers, holographic and steep-edge long-pass filters to eliminate the relatively intense (Rayleigh) scattered laser light, and low-noise multi-element photodetectors and cameras.

The most economical and compact lasers are based on semiconductor diode lasers. But to be used in Raman, the laser wavelength needs to be both ultra-narrow and stable. A proven approach is to use a Fabry-Perot diode laser chip and lock its output to a type of filter called a Volume Bragg Grating (VBG). That’s the basis of the Digital-D Type laser modules that Innovative Photonic Solutions (IPS) manufactures with single-frequency output for OEM manufacturers of Raman microscopes, instruments, and researchers. IPS lasers are offered at the popular Raman excitation wavelengths of 638 nm and 785 nm and several other wavelengths. But the nature of diode laser chips meant it was not trivial to deliver the reproducibility and reliability needed for most Raman applications.

The Solution

Dr. Greg Charache is VP of Photonics at IPS. He explains, “It is well known that the most common cause of failure in single-spatial-mode diode lasers is Catastrophic Optical Damage (COD) to the vulnerable output facet of the diode chip where high laser intensity can lead to overheating and eventually melting of the semiconductor.” For example, COD limited the lifetime of early high-power direct diodes until Coherent pioneered a solution in the form of aluminum-free active area, AAA, and diode laser devices. But COD can still potentially occur in diode lasers at any power level due to back-reflections from downstream optics.

Charache adds, “Raman microscopes are optical systems that are very precisely aligned. So they can generate back-reflections from highly polished samples such as silicon wafers and sample support like glass slides. The result is that the beam is “folded” and can be reflected all the way back into the diode laser chip itself, causing COD. And further investigation by IPS revealed that many researchers outside the semiconductor industry also use silicon wafers to align their Raman microscopes, since the wafer is atomically flat and generates a strong Raman signal. While this allows for easy calibration and alignment of these confocal systems, we believed it was the culprit leading to early failure of some of our laser modules.”

The easiest way to eliminate these types of back-reflections is to use a device called an Optical Isolator, which acts as a one-way valve for light. By the clever combination of optical polarizers and waveplates, an optical isolator allows efficient (e.g., >92%) forward transmission of light while effectively blocking light transmission in the reverse direction, e.g., >33 dB of attenuation.

After extensive testing and evaluation in their product development lab, IPS selected Tornos optical isolators from Coherent, customized specifically for IPS. These isolators contain optically-contacted polarizing beam splitter cubes resulting in higher transmission compared to other available isolators. Charache states, “We now offer all our Digital-D type modules with the option of a fully integrated Tornos optical isolator. We recommend this option for all our Raman customers, particularly for OEMs producing microscopes as well as end-users building their own microscopes.”

The Result

The results of this change were immediate and dramatic according to Charache. He says, “We went from a situation where we had a steady stream of field failures due to COD in these laser modules to a complete elimination of the problem. Everyone has benefited. We don’t have the risk of unhappy OEM customers, and they don’t have to worry about any potential negative brand image impact due to laser unreliability. And most important of all, the end user can schedule and perform experiments with their Raman microscopes without worrying about possible laser failure. I say schedule, because a lot of Raman microscopes are intensely used as shared analytical instruments, which of course only works well when you have performance-on-demand.”

In addition to the main applications of Raman microscopy, Raman spectroscopy, and process Raman, Charache notes that the turnkey simplicity – and now high-reliability – of these single-frequency semiconductor lasers modules are making these products popular in other demanding applications including metrology and interferometry, atomic clocks, and cutting-edge research in quantum computing.

“We recommend the option of Tornos optical isolators for all our Raman customers, particularly for OEMs making microscopes."

— Greg Charache, Vice President of Photonics, IPS, Plainsboro, New Jersey

Figure 1. Digital-D laser modules from IPS feature single-frequency output that is ideal for Raman applications.

Figure 2. IPS uses customized Coherent Tornos Isolators to completely eliminate back reflections into the laser module that could damage the diode laser chip.

Figure 3. Raman microscopy is used in life sciences and elsewhere to acquire a multi-dimensional “map” of specific chemicals, often represented in false color. Image courtesy IPS.