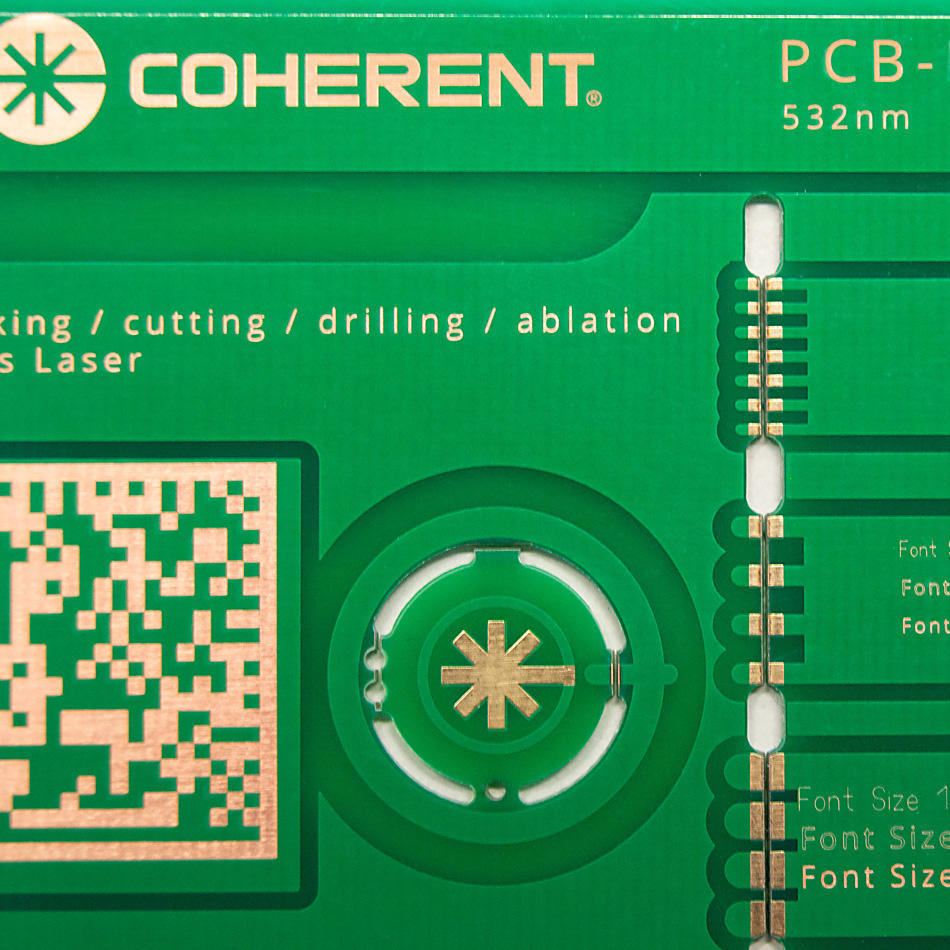

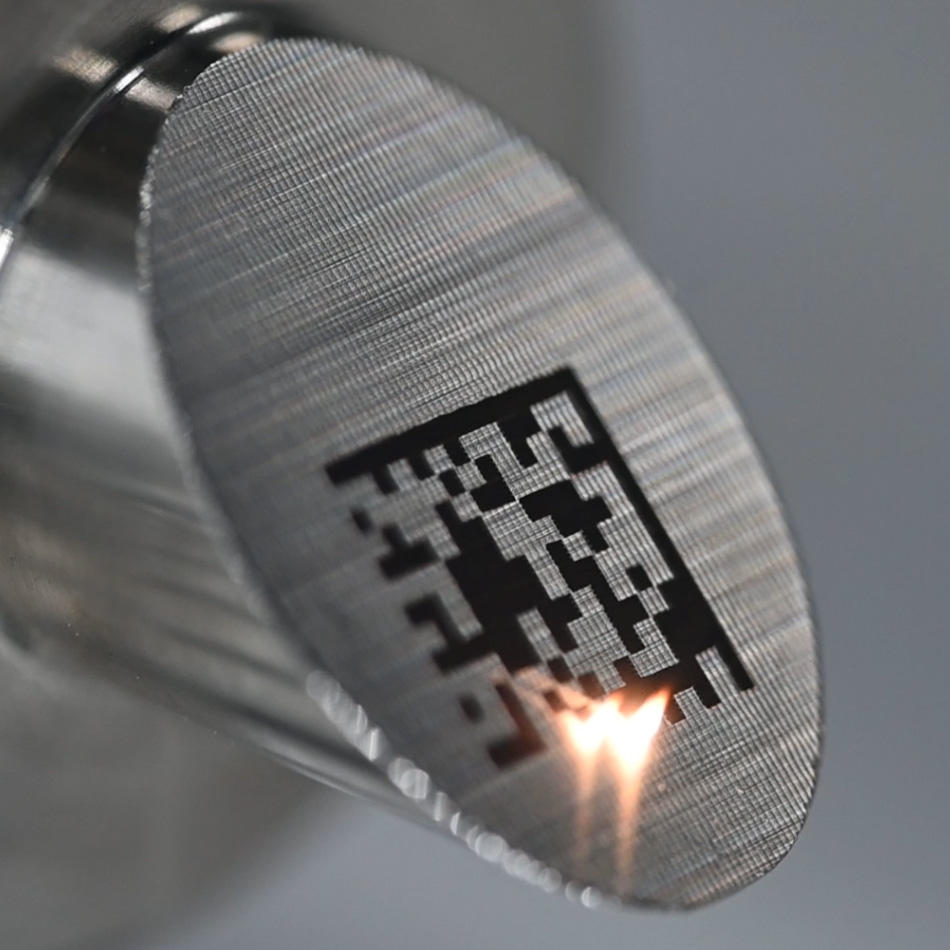

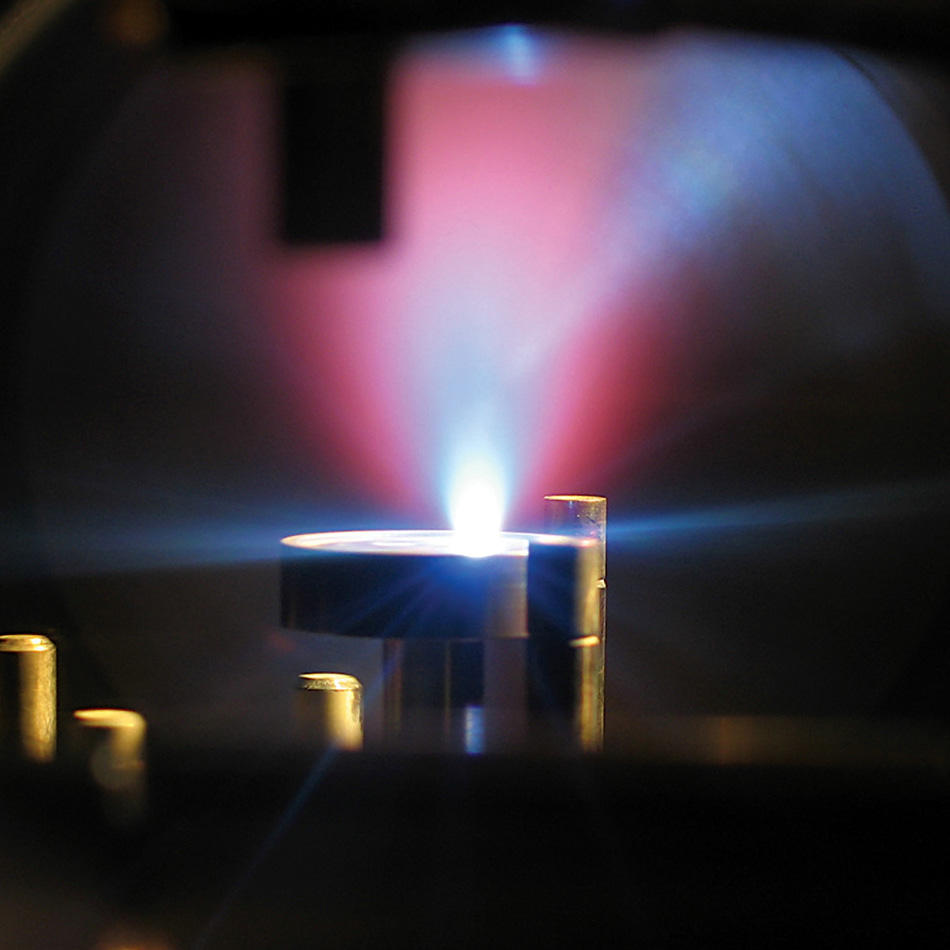

Industrial

Solutions start here

See how we're powering manufacturing outcomes in the world's most innovative markets — from semiconductors to EVs.

Ready to Get Started?

Share your contact info and a specialist will reach out.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.