WHITE PAPER

OPSL Advantages Whitepaper Series #4:

Superior Reliability – Huge Installed Base

Overview

The optically pumped semiconductor laser (OPSL) is a unique, patented technology that provides superior reliability and longevity compared to other continuous wave (CW) solid state lasers. Together with other OPSL advantages, this reliability is confirmed by an installed base exceeding 100,000 lasers in diverse and demanding applications from life sciences to light shows.

OPSL Advantages White Papers in this series:

#1. Wavelength flexibility

#2. Invariant beam properties

#3. No mode noise ("green noise")

#4. Superior reliability - huge installed base

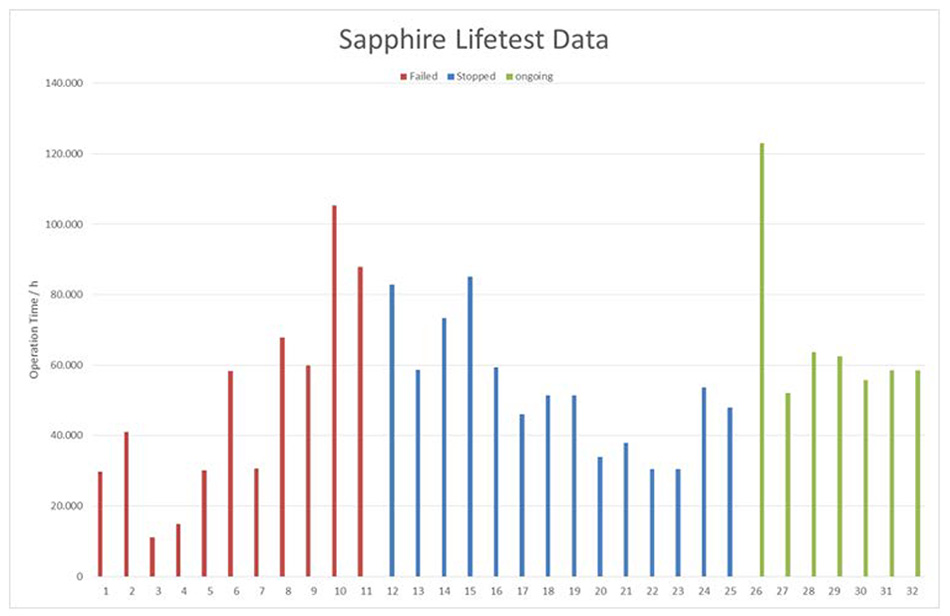

Unmatched Visible and UV Reliability

Applications for continuous wave (CW) visible and ultraviolet lasers have been supported by several different technologies over the past 50 years. First there was the ion laser, then lamp-pumped solid state, diode-pumped solid state (DPSS), laser diode modules, and now OPSL technology. As a leading laser manufacturer, Coherent has developed numerous successful products using all these different technologies. This gives us a unique perspective to objectively compare the performance and advantages of each type with our unrivalled field experience. Of all these laser types, OPSLs have proven to be one of the most reliable and to deliver very long lifetimes – see figure 1. For example, our low power OBIS and Sapphire product lines have a demonstrated B5 value of 20,000 hours. This impressive number means 95% of these lasers are still delivering specified performance after 20,000 hours of operation. No other visible or ultraviolet CW laser technology can surpass this statistic.

The combination of high reliability and long lifetime is a key factor in the market success of OPSLs, to both end users and OEMs alike. This market acceptance and success is evidenced by nearly 100,000 OPSLs now in the field, at powers from milliwatts to multiple watts. In such diverse applications as life science instrumentation, semiconductor inspection and spectacular outdoor light shows, OPSLs from Coherent have established themselves as the first choice in visible and ultraviolet CW lasers. Moreover, in life sciences, many OEMs are now designing their third and fourth generations of instruments, all using Coherent OPSLs.

Figure 1: Ongoing lifetests on 32 random (Coherent Sapphire) OPSLs showing the extremely long lifetime statistics typical of this technology.

Reliable De-Rated Pump Diodes

A laser is only as reliable and dependable as its components. A key active component in an OPSL is the pump diode that performs the initial electrical power to optical power conversion. The OPSL utilizes a near infrared InGaAs gain chip. One of the advantages of this arrangement is that this gain chip is optimally pumped by 808 nm light. This enables the use of gallium arsenide (GaAs) based pump diodes. GaAs diodes represent some of the most mature semiconductor laser technology with an incredible longevity track record in telecom and data storage.

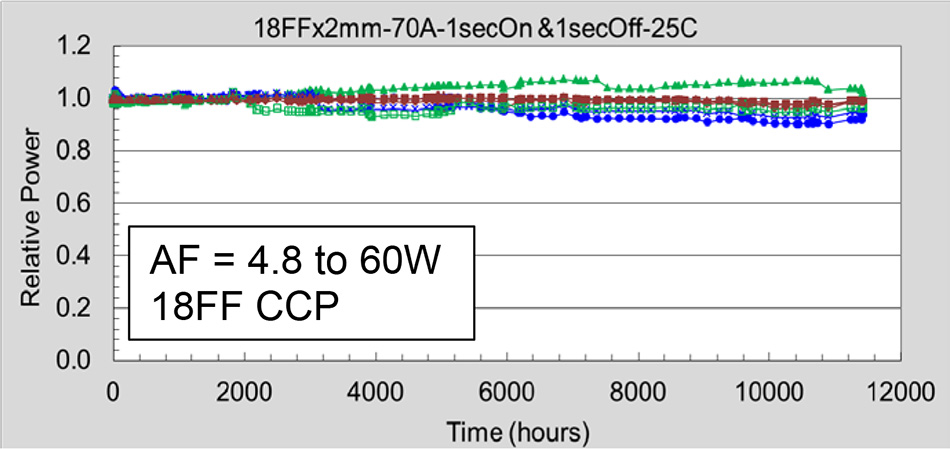

Coherent is a vertically integrated laser manufacturer, where we design, fabricate, assemble and test all critical components and sub-assemblies in house. As such, we have always been at the forefront of 808 nm diode development, pioneering many of the innovations that have pushed lifetimes to tens of thousands of hours. Some of these well-documented advances have included the development of aluminum-free active area in the diodes themselves (called AAA™ Technology), and packaging technologies such as the first use of hard solder. Moreover, the acquisition of the DILAS team has brought even more packaging expertise to Coherent.

Figure 2: Coherent increased the lifetime of 808 nm diodes with the introduction of our AAA™ Technology. These typical lifetest data were recorded at an operating temperature of 25ºC and extrapolate to a device lifetime of >50,000 hours. These diodes are key components in our OPSLs.

Unlike many other laser diode types, the 808 nm pump diodes used in our OPSLs can produce high power densities at room temperature. This eliminates the need for costly and complex cooling components, and eliminates these cooling systems as possible failure mechanisms. Of course, laser diode emission wavelength changes with temperature. But the absorption bandwidth of the gain chip is very broad, unlike the narrow absorption peaks of crystals used in a DPSS laser. There is thus no requirement to precisely maintain the pump diode wavelength and hence temperature. This eliminates another possible mechanism for long-term performance degradation.

In addition, the pump diodes in Coherent OPSLs are always operated at de-rated power levels with significant headroom. This is a major factor in the long lifetime of these pump diodes and allows the drive current to be safely increased to offset any natural minor long-term aging of the pump lasers.

Reliable, Stable Gain Medium

The semiconductor gain chip is another critical component and one that is unique to the OPSL. The gain disk is actually an optically pumped vertical cavity semiconductor laser (VCSEL), to give it its full name. This monolithic III-V semiconductor chip contains layers of ternary quantum wells (InGaAs) alternated between binary (GaAs) layers. The major advantages of the VCSEL architecture arise because the output is emitted perpendicular to the active junction, i.e., through the large area of the device rather than through a narrow asymmetric edge facet. The result is a large diameter circular and symmetric output beam. This results in much lower optical power density at the output facet than for typical edge architectures as used in visible diodes. This is a major differentiator between OPSLs and visible laser diodes, enabling simple power scaling in OPSLs and eliminating facet power damage as a failure mechanism. Since facet damage is still a leading failure mechanism in some visible diodes, avoiding high facet intensity is one of the reasons that visible and ultraviolet OPSLs have longer inherent lifetimes than their direct diode counterparts. And, because the gain medium is a large area semiconductor, it does not suffer from any build-up of color center defects which arise in many crystals used in diode pumped solid state (DPSS) laser alternatives.

The two critical active components in an OPSL – the pump diodes and the gain chip – therefore both offer the clear potential for much better reliability and longer lifetimes. To fully exploit this potential, Coherent has utilized several important design innovations derived from our fifty-plus years of experience as a supplier of lasers to OEMs, industrial processes, and scientific applications.

Monolithic Construction and PermAlign Technology

A major reason why the performance of many legacy lasers degrades over time is loss of cavity alignment. Repeated natural thermal cycling and the long-term impact of ambient vibrations and handling shocks can cause laser cavity optics to shift. At a minimum, this can result in compromised mode quality, such as a TEM00 laser degrading to a multimode output beam. It can also result in power degradation, and in the worst case, this can prevent lasing altogether. Historically, such shifts were corrected by the end user or service engineer “tweaking” the optic(s) back into proper alignment. Laser manufacturers like Coherent realized long ago that this was not a viable or acceptable solution in modern applications, particularly where the laser is buried in an OEM instrument. We use two of our time-proven solutions in our OPSLs to eliminate misalignment as a failure mechanism.

Figure 3: Coherent produces OPSLs over a wide range of powers from the tiny milliwatt level OBIS Core lasers for instrumentation OEMs to the multiwatt Genesis series.

Coherent produces OPSLs over a wide range of output powers – figure 3. In our smaller OPSLs such as Sapphire and OBIS lasers, the laser cavity is assembled on a small ceramic plate. Furthermore, our OPSLs make extensive use of our unique and patented PermAlign™ mounts. Most adjustable optomechanical mounts include adjustment screws and one or more locking screws that attempt to freeze the final adjustments(s). But even in high quality mounts of this type, their alignment can creep over time due to ambient vibrations and/or mechanical impacts, as well as thermal influences because of their use of different metals. In contrast, PermAlign™ mounts are single piece metal mounts to which the optics are permanently soldered. The shape of the metal mount itself is then finely adjusted to its final alignment while monitoring beam alignment and laser performance. Thus, there are no parts which can move or slip in such a mount.

Other Practical Considerations

Our long experience in designing and manufacturing lasers was used to eliminate two other potential sources of performance degradation or failure in our OPSLs; heating in the gain medium and contamination of optical surfaces. Specifically, we implemented an effective cooling scheme to directly lower the temperature in the OPSL gain chip. This cooling scheme is based on a new, proprietary mounting technique which directly attaches the chip to a heatsink. This is one of the key factors responsible for the long lifetime of these OPS lasers. Efficient cooling of the gain chip has the added benefit of allowing higher power to be extracted from a given device size.

In addition, we have implemented the use of HALT (Highly Accelerated Life Testing) during product design and HASS (Highly Accelerated Stress Screening) during product manufacture. The concept of HALT is in answer to the question, “how do you maximize the reliability of a product design, without building hundreds of units and testing for tens of thousands of hours?” During development, engineering units are stressed far beyond their normal operating conditions (typically with temperature, mechanical shock/vibration, drive current/power, or a combination of these parameters) to create failures. These failure modes are then analyzed and “designed out” of the product; elimination of the failure modes from extreme conditions ensures that those same failure modes can have no impact at normal operating conditions. HASS, on the other hand, uses similar but less extreme conditions (still outside of standard operation) to screen for material issues or workmanship failures. A combination of HALT and/or HASS is used across technologies and products, guaranteeing reliable product designs and shipment of long-life products.

Finally, maintaining pristine optical surfaces in a laser is a seemingly mundane but absolutely critical factor in enabling long laser lifetime. The reason is that micro-contaminants can accumulate on these optical surfaces, ultimately leading to absorption, laser power loss and sometimes even damaged optics. For OPSLs, we adopted rigorous solutions used in our industrial ultrafast lasers to build and maintain a contamination-free sealed cavity. In particular, this means careful choice of materials, including minimized use of non-metals. Today, the only intracavity organics that we use are materials that Coherent engineers have already exhaustively tested and qualified for outgassing and compatibility with laser optics. In addition, experience with long-lived industrial UV lasers has also shown that our factory cleaning protocols for both the mechanical and optical components are equally important. Even trace amounts of contaminants, such as oil or lubricant, can eventually migrate from metal parts to optical surfaces, requiring cleaning or replacement of the optics. We have proven methods to remove any traces of these materials.

Summary

To summarize, OPSL technology is inherently robust and can deliver long lifetimes with reliable performance. At Coherent, we have used our unmatched experience in diverse laser technology to develop practical OPSLs that fully deliver on this intrinsic potential. With nearly 100,000 of our OPSLs now successfully operating in the field, the market has confirmed that these are the most reliable lasers we’ve ever produced.