効果的、経済的、高精度の三拍子揃ったCoherentのSmartSense+によるレーザ加工方法監視

SmartSense+ソリューションが要求の厳しいレーザ切断やレーザ溶接、レーザドリリング、レーザマーキングの用途において品質を向上させスクラップ率を低減させます。

2022年4月12日、Coherent

CoherentによるSmartSense+の新発売により、レーザ加工方法監視がかつてないほど簡単で身近なものになりました。レーザ加工の仕上がりと再現性を向上させ、トレーサビリティと文書化機能を提供するこのアクセサリ。後者は特に医療機器やeモビリティ、マイクロエレクトロニクス などの高精度な製造用途に極めて重要です。

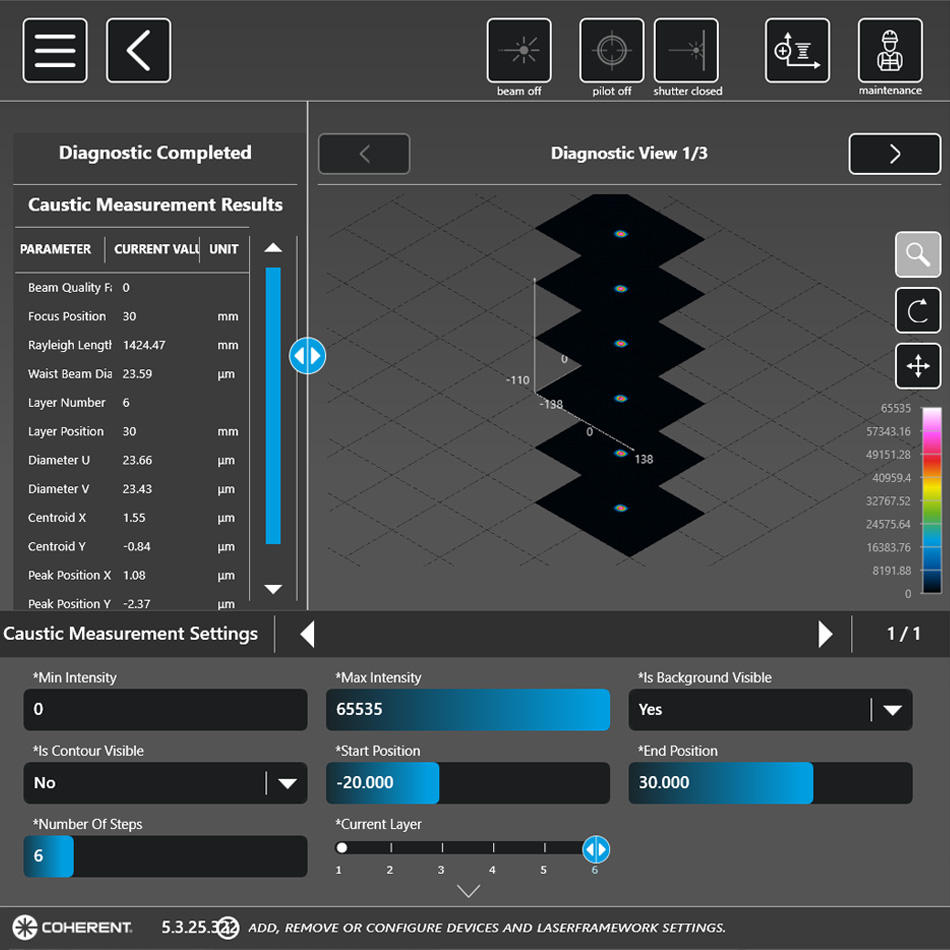

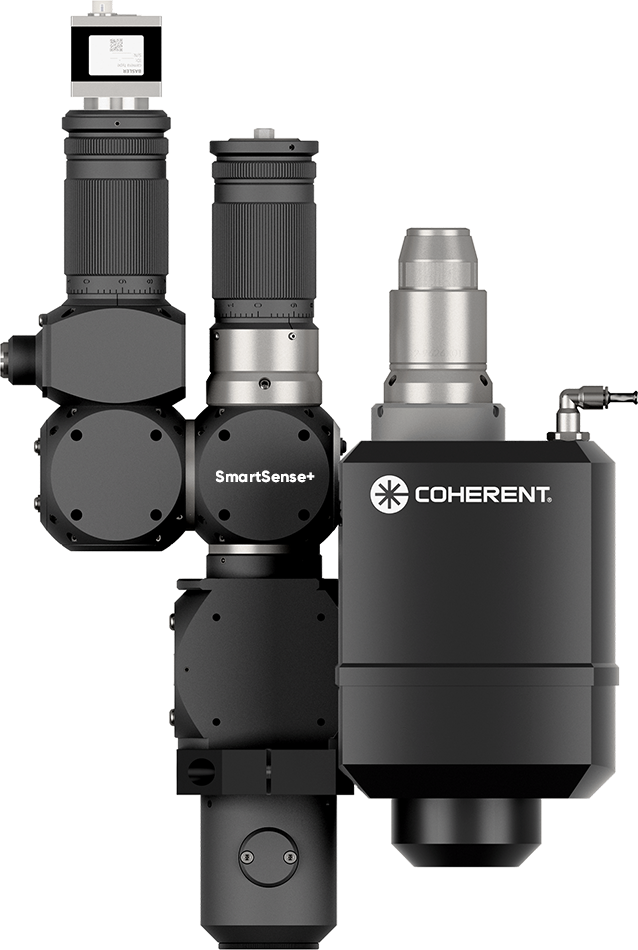

SmartSense+とは、光学検出器と(オプションで)音響センサーを内蔵し、データ取得とシグナル処理になくてはならないエレクトロニクスとソフトウェアをすべて搭載した一種のオプトメカニカルアクセサリです。CoherentのExactCutやExactWeld、StarCut、MPS、PowerLineシリーズのレーザシステムに容易に組み込むことができます。SmartSense+の動作は、Coherentの内蔵型ソフトウェアプラットフォームLaser FrameWorkの一部として該当するシステムに搭載されています。SmartSense+はCoherentのファイバーレーザ、半導体レーザ、超短パルス(USP)産業用レーザのいくつかとの互換性も備えています。

測定できなければ、改善は不可能

質の高い仕上がりと製品間やバッチ間の一貫性を要求する用途では、リアルタイム、インラインのレーザ加工方法監視が必須です。また、レーザ加工のばらつきを早期に発見することで、不良部品の組み立て前や最悪の場合、顧客への出荷前に生産を停止したり修正する機会を提供します。

詳細なインラインの加工方法監視で採用されている最も一般的な技術は、高速度カメラと光コンピュータトモグラフィ(OCT)測定の2つです。高速度カメラの欠点はコストが高いことと、溶接で特に重要な部品表面の下を見る機能がないことです。OCTでは、その表面下のビューが得られますし、溶接中にキーホールの深さを測定することも可能です。しかしこれらを導入するには莫大な費用がかかります。

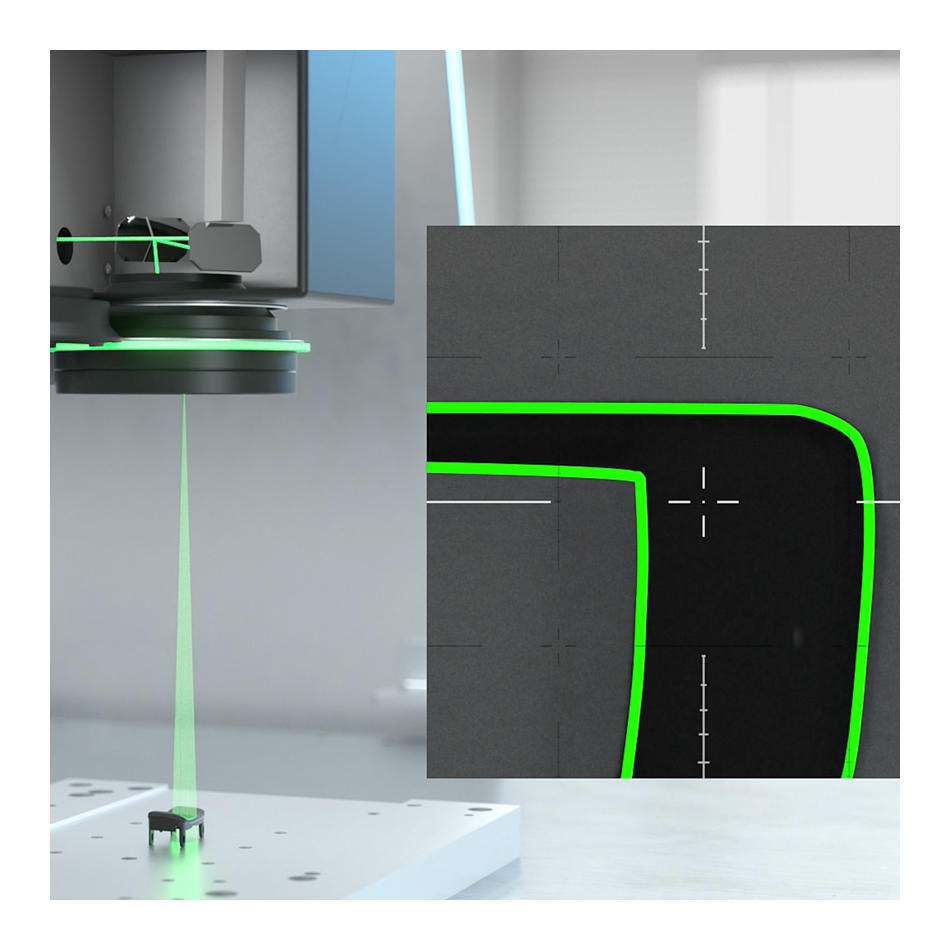

SmartSense+なら、それと同様の表面ならびに表面下のレーザ加工の動的ビューが得られます。ただし、本質的に複雑さもコストも低減されるアプローチを採用しているという利点を兼ね備えています。SmartSense+光学システムは、後方反射レーザ光をキャプチャするほかプロセスそのものから放出される光もキャプチャします。この光は可視域、レーザ波長域、近赤外線域(NIR)のコンポーネントに分けられ別々の3つの検出器へと送られます。

これらの信号が相互に、レーザ光の吸収率やレーザ加工で発生するプラズマ(電離プルーム)の特性、部品の表面温度などの詳細情報を提供します。また、圧電式接触センサーとマイクロフォンを用いた音響信号検出オプションによって、溶接中や溶接後の接合部の高温割れなど、より包括的なプロセス指紋の取得が可能となります。

SmartSense+はその名のとおりスマート

OCTの特長の一つとして、溶接の深さや溶接シームの幅などの幾何学的な情報を直接測定できるということが挙げられます。これに対して、SmartSense+で得られる光および音響測定値は「絶対的」なものではありません。このことはつまり、どの信号が「優良」なプロセスを示し、どの信号がエラー(エラーの重大度も含む)を示すのかを立証するためにテストを行う必要があることを意味します。

SmartSense+の制御ソフトウェアを使えば、これらすべてに難なく対応し極めて効果の高い結果を得ることができます。実際、この目標の達成のために2つの方法が用意されています。

1つ目は「パスウェイ判断」による方法です。これは、プロセス実行を複数行い、各センサーの信号曲線の最も高いものと低いものを実際の結果と関連付け、それぞれの許容動作帯域を立証するという方法です。生産中にこの限界値(パスウェイ)を超えたプロセスには即座にフラグが立てられます。

2つ目は学習アルゴリズムや人工知能(AI)を使用して一連のテストを分析し、良い結果または悪い結果に相関させるという方法です。この方法で「学習した」システムは、高い信頼度と成功率で実際のプロセスを測定し品質を判断することができます。この方法の優れたところは、確立されたプロセスに対し単に実行か中止かを示すだけでなく、プロセスが失敗した理由までも示すことができるという点です。

SmartSense+はレーザ加工の詳細を提供します

では、SmartSense+はこれらの情報を使用して実際にどのようなものを測定できるのでしょうか。実にさまざまなものを測定できます。溶接プロセスでは、たとえば次のデータが提供されます。

プロセス:

- 溶接プロセスが実際に行われたかどうか

- 水平部品と垂直部品のギャップ幅

- プロセスとシールドガスフローの変化

レーザ動作条件:

- 出力密度の変化

- レーザ出力の変動

- レーザスポットの焦点位置の変化

溶接品質の評価:

- 汚れや傷などの表面欠陥

- 溶接物の穴、空隙、マイクロクラック

- 溶け込み不足、アンダーカット

- 「ハンピング」

- スパッタ

SmartSense+は高品質のプロセスデータを提供する以外に、汎用性が高いという利点も備えています。高いデータ取得率を使用することで、連続発振(CW)レーザとパルスレーザの両方での動作が可能となります。さらに、高出力産業用レーザと低出力産業用レーザの両方を正確に測定することもできます。また、この種の加工方法監視は、従来はレーザ溶接でのみ使用されていたものですが、SmartSense+が提供する情報のおかげで切断やマーキング、彫刻、さらに洗浄などの用途にも役立てられるようになりました。

詳しくは、SmartSense+とCoherentのLaser FrameWorkの詳細情報をご覧ください。

関連資料