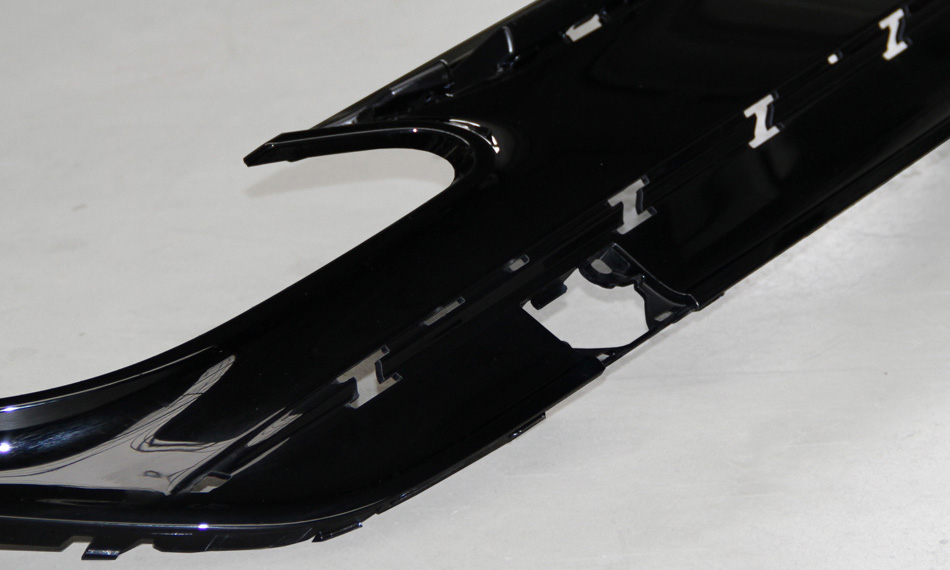

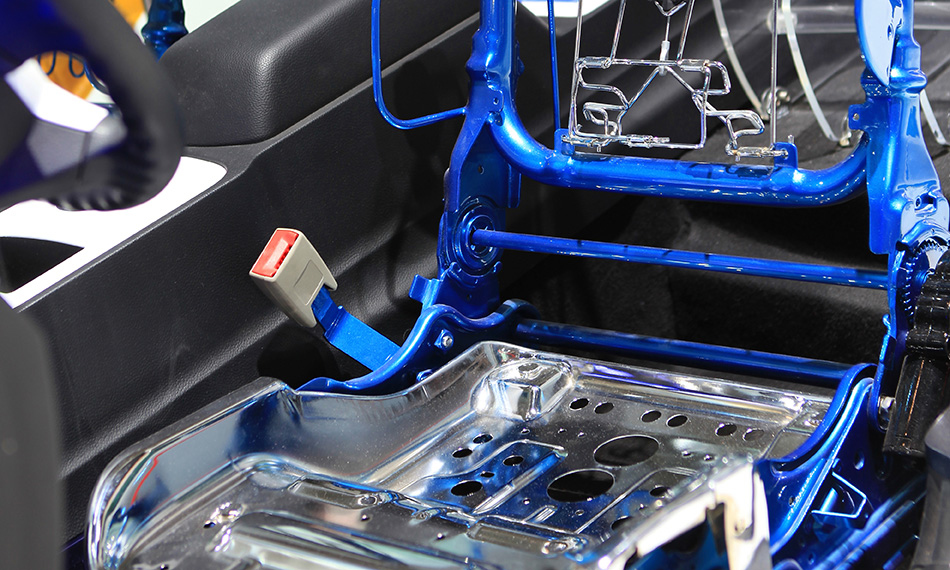

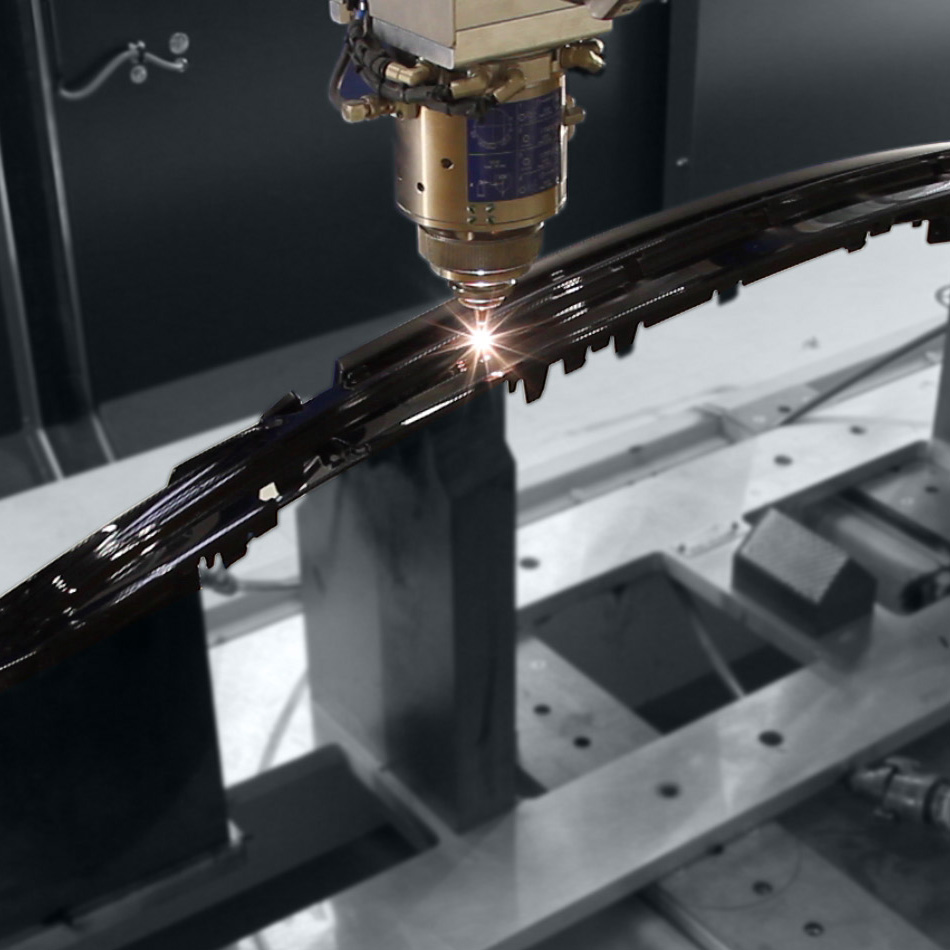

汽车内饰

使用高效的激光器和系统,提高加工汽车内饰和组件时的生产效率和质量。

- 柔性生产 利用软件控制的激光加工,轻松实现大规模定制。

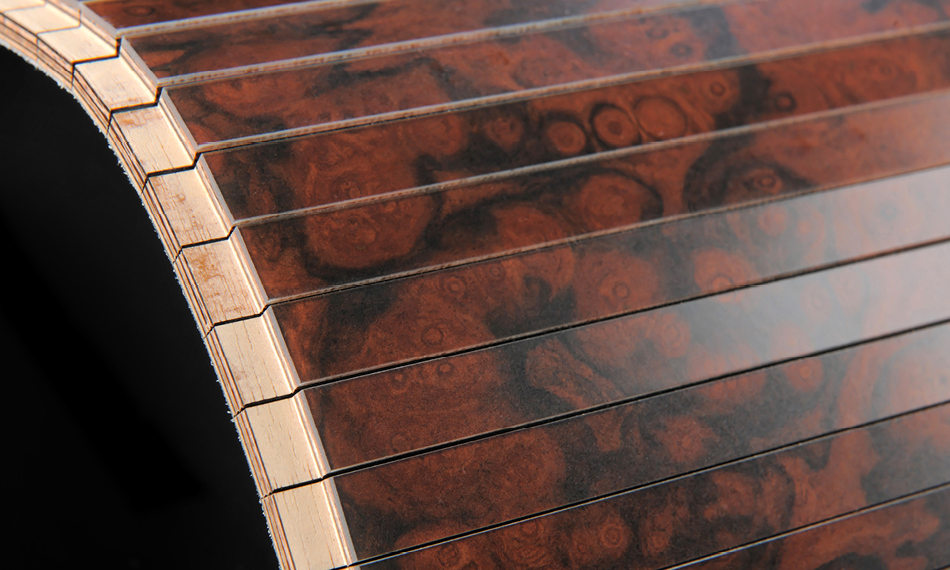

- 有吸引力的激光美容 在美观的可见表面上进行标记、切割和焊接。

- 减少返工 使用一致、无磨损的激光器工具实现更高的精度并消除返工。

品质内在

许多汽车内饰部件的加工必须具有高美学品质,因为这些部件可能对消费者可见。此外,内饰中使用各种各样的材料——金属、聚合物、薄膜、有机物、玻璃等等,而且经常需要定制它们的加工过程。人们需要能够提供操作灵活性和卓越结果的生产工具。解决方案:Coherent 激光器

让我们开始行动

请向我们提供一些有关您的信息,产品专家将在 2 个工作日内与您联系。

产品应用

内饰产品

Global Customers

成功案例

Bröking-Plastex:CO₂ 激光器助力汽车大规模定制

了解 Bröking-Plastex 如何使用 Coherent CO₂ 激光器提高汽车零部件的生产成本效益和大规模定制。

资源列表

准备好开始了吗?

分享您的联系信息,我们的专家会与您联系。