Laser Machines and Systems

AP 530

Fully automated laser system for marking and surface texturing of medical devices, configured for tubular and free-form part shapes.

These systems incorporate multi-axis robotic part loading/handling, machine vision/validation, a choice of laser sources (fiber laser, solid state, or ultrashort pulse), and available parts inspection. Operator intervention is reduced to a few times per shift.

AP 530 – Key Features and Options

Optimize your manufacturing with numerous laser choices and setups configured for handling tubular or free-form parts.

Product Specifications

| Product Name | Application | Setup | Laser Option(s) | Other Options |

AP 530 M |

Tube marking, Dimpling, Surface Texturing |

Single Rotary (Gen I) Dual Rotary (Gen II) 6-Axis Robot & Z-Axis |

Monaco, Rapid LX, PowerLine E/F series |

Tray loading for thinner tubes and wires |

AP 530 S |

Free-form Surface Texturing /Marking/Black Marking |

6-Axis Robot & Z-Axis 3D vision system |

Monaco, Rapid LX, PowerLine E/F Series |

Post process validation |

Featured Blog

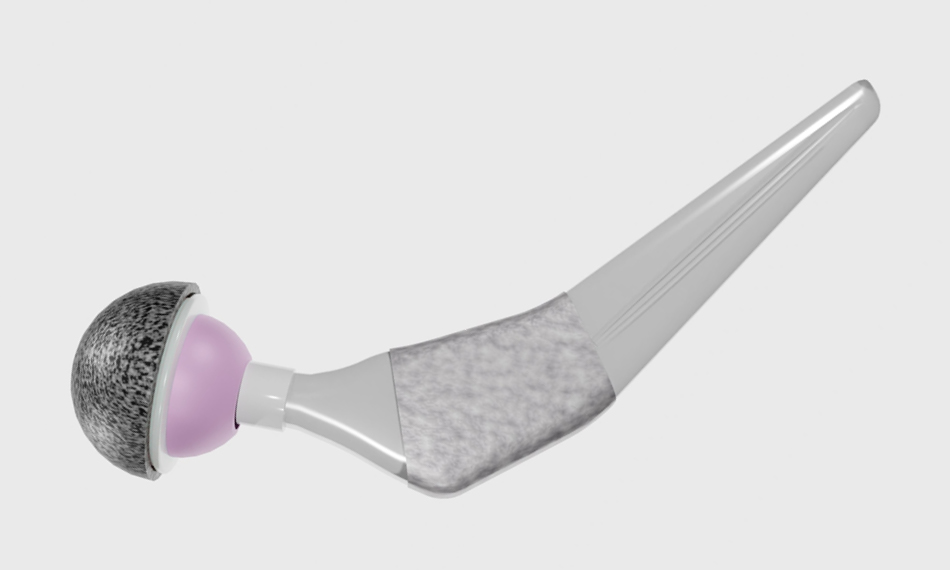

Coherent Announces Surface Texturing Solution for Medical Implants

The new AP 530 S uses 6-axis robotic part handling to accommodate implants of all shapes and sizes.

Video Spotlight

Laser Texturing and Marking for Medical Implants

The new Coherent AP 530 S is a fully automated laser-based machine for creating precision surface textures and/or permanent marks on implantable medical hardware and other devices with complex freeform shapes.