Laser Texturing/Marking of Medical Implants

The Coherent AP 530 S combines robotic motion, a USP laser, and user-friendly software to simplify laser structuring of shaped implant surfaces.

February 02, 2023 by Coherent

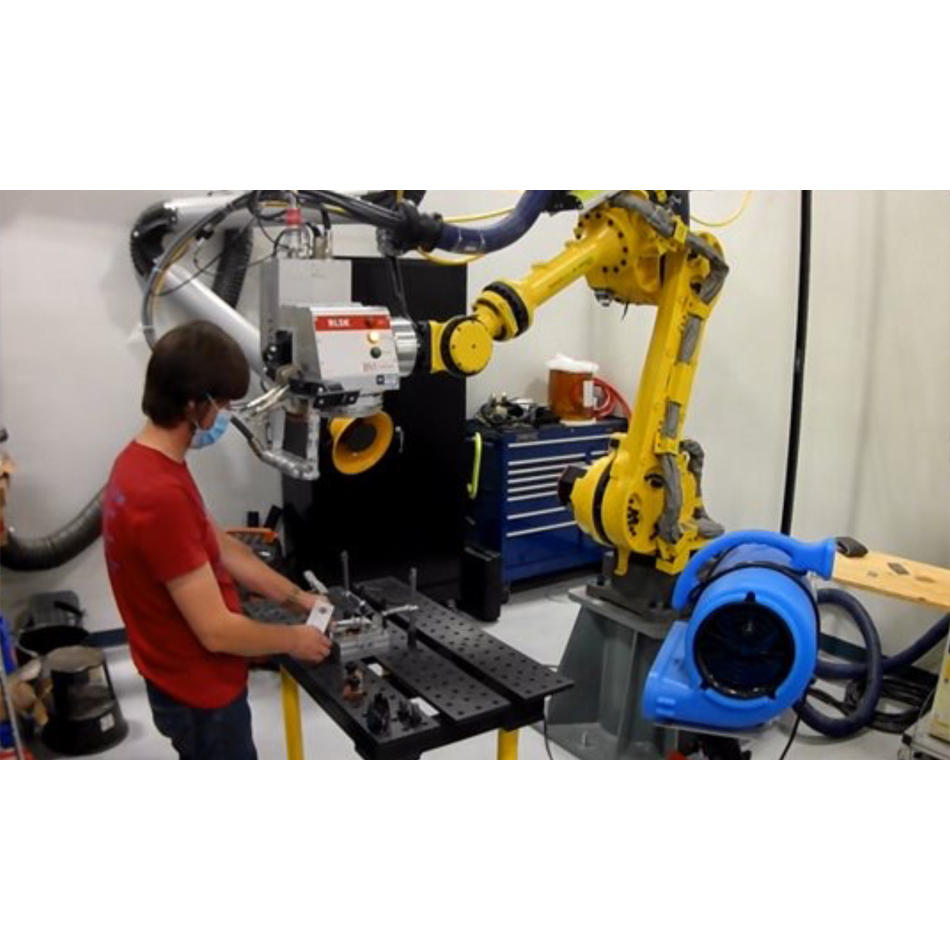

The new Coherent AP 530 S is a fully automated laser-based machine for creating precision surface textures and/or permanent marks on implantable medical hardware and other devices with complex freeform shapes. This unique system incorporates an ultrashort pulse (USP) laser and a 6-axis robot for complete shape versatility and automated operation, i.e., batch processing with minimum operator intervention.

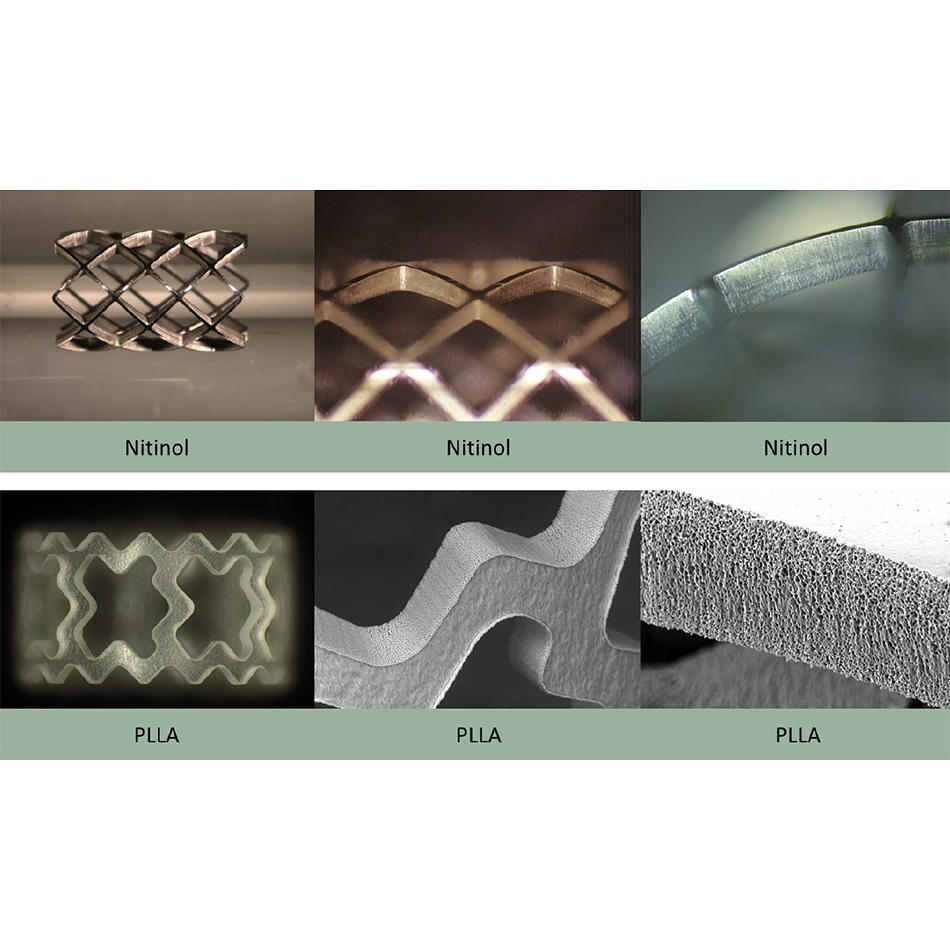

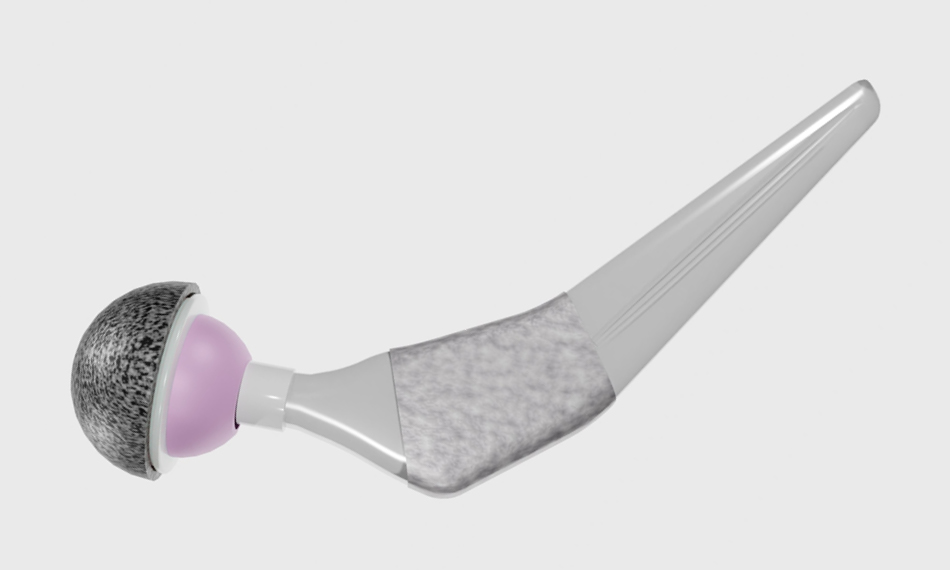

Unlike traditional methods like sand-blasting and other mechanical means that can only create stochastic surface textures, the AP 530 S provides a deterministic alternative that gives the user complete control over feature size and depth, feature density, spatial distribution, and other texture details. This deterministic control of surface texturing can produce orthopedic implants for enhanced osseointegration and vascularization characteristics. In addition, laser texturing is a cleaner process that avoids the possible contamination by sand-blasting and other mechanical methods. The AP 530 S also supports other types of surface functionalization as well as complex marking applications.

With its user-friendly software, the AP 530 S is easy to integrate into any production environment.

The use of a 6-axis robotic part handling system enables texturing and/or marking on selected surfaces of any shape or sized orthopedic device up to a hip implant. This robotic handling offers complete coverage of the part with enhanced 3D vision for parts and process verification. The machine can learn the part shape and details using this 3D vision system, or it can work directly from a CAD file. The operator then specifies the location(s) and texture details to be applied. Automated vision registration supports batch loading of parts, providing longer unattended process time with complete logging and tracking. This minimizes labor costs and eliminates potential errors associated with manual operation. In addition, the AP 530 S is Industry 4.0 ready and its user-friendly software also simplifies integration into any production environment.

The AP 530 S gives the user complete control over feature size and depth, feature density, spatial distribution, and other texture details of orthopedic implants.

The AP 530 S is available with several different laser types and several different laser power levels. A femtosecond laser is the optimum tool for texturing stainless steel, titanium, and other bio-compatible metal surfaces. A picosecond laser is recommended for corrosion-resistant black marking that is ideal for UDI and production tracking. In addition to these USP lasers, the AP 530 S is also offered with a nanosecond laser to support conventional laser marking and engraving tasks.

Learn more about the Coherent AP 530 S.