Multi-Wavelength Laser Engines–The Future of Life Science Instrumentation

Manufacturers of life science instruments such as flow cytometers are increasingly moving from discrete lasers to laser engines – compact, customizable assemblies that deliver shaped focused beams in application-specific formats.

June 1, 2022 by Coherent

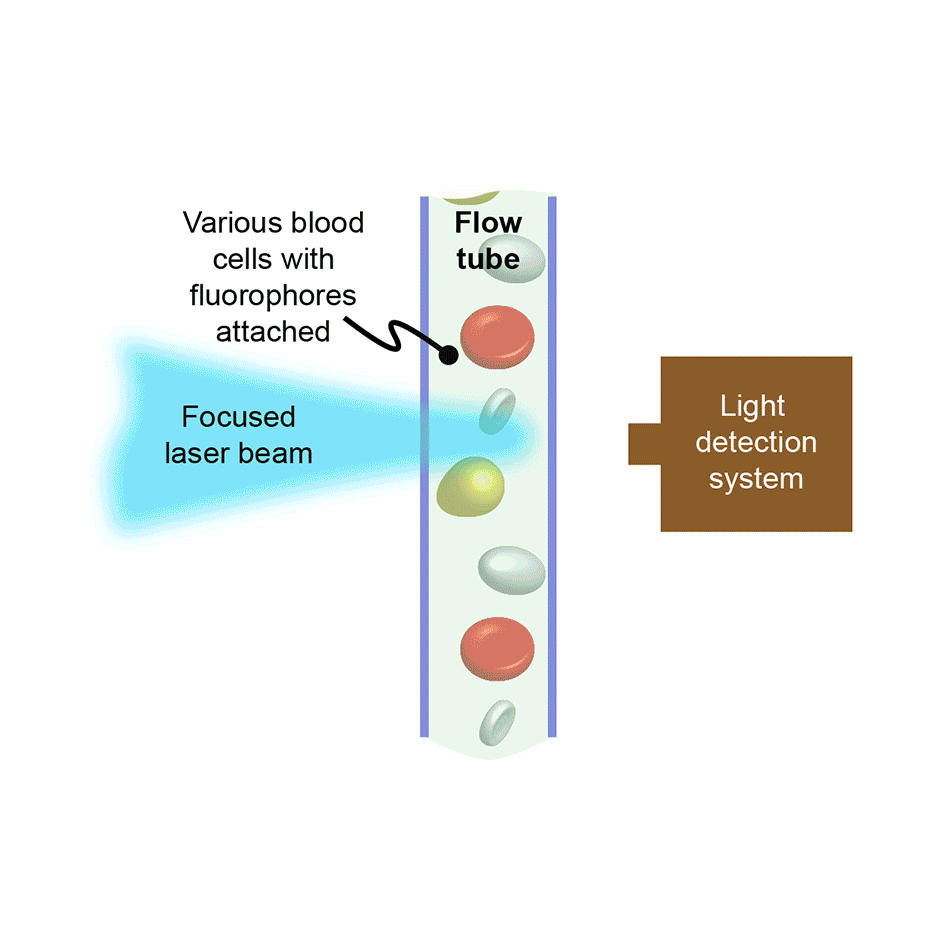

A laser produces a beam of light, either pulsed or continuous-wave. Just about everyone knows that. And life sciences represent a huge market for continuous-wave lasers. But virtually none of the instruments or applications in life sciences actually use the beam in the native form that the laser produces. They focus it, shape it, combine it with other laser beams, couple it into fiber optics, modulate it (on/off), etc., as needed to perform specific tasks from counting blood cells, to getting microscope images of live tissues, to genetic sequencing.

Now some of these laser beam modifications turn out to be quite tricky. For example, it can take a skilled, experienced laser technician several hours to couple a single laser into a high-performance optical fiber. For a system needing multiple laser wavelengths, we might be talking about even days of painstaking alignment work.

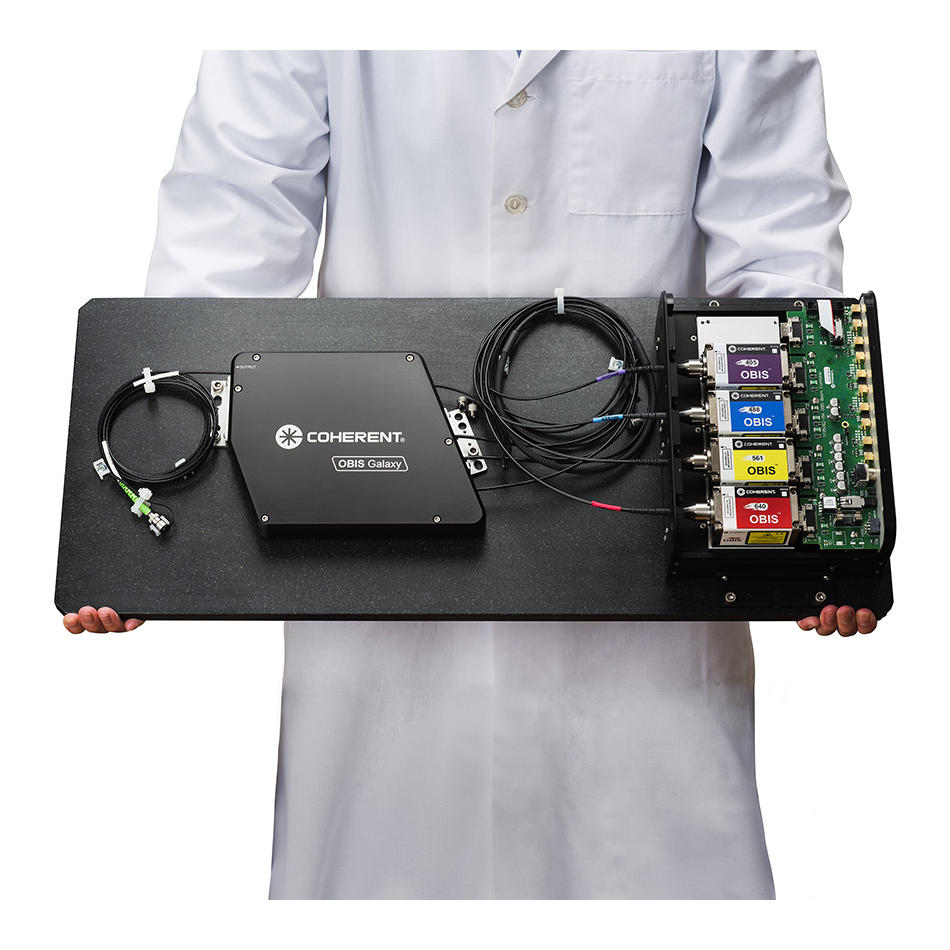

A Galaxy not very far away

It seems obvious now, but it was a revolutionary idea when Coherent set out to address this challenge. Specifically, providing assemblies that take care of complex beam modification tasks internally, and deliver laser output in the form needed by the application. Our first product venture down this path was called Galaxy. It brought plug-and-play functionality to instrument OEMs and laboratory laser users needing multiple wavelengths delivered in a single fiber. For the first time ever, lasers could be effortlessly added or replaced in a system in seconds or minutes, rather than hours and days, all using standard fiber connectors.

It turned out to be perfect for lab researchers in applications like confocal microscopy where they often want to quickly switch between different wavelengths to image different biochemical targets in the same sample. And it was adopted by OEM instrumentation manufacturers too. They liked it because it allowed them to do things like “hot swap” lasers in the field, either to add extra wavelengths, upgrade the power at specific wavelengths, or to replace failing lasers, without the need for factory returns and associated customer downtime.

Multi-wavelength engines you can count on

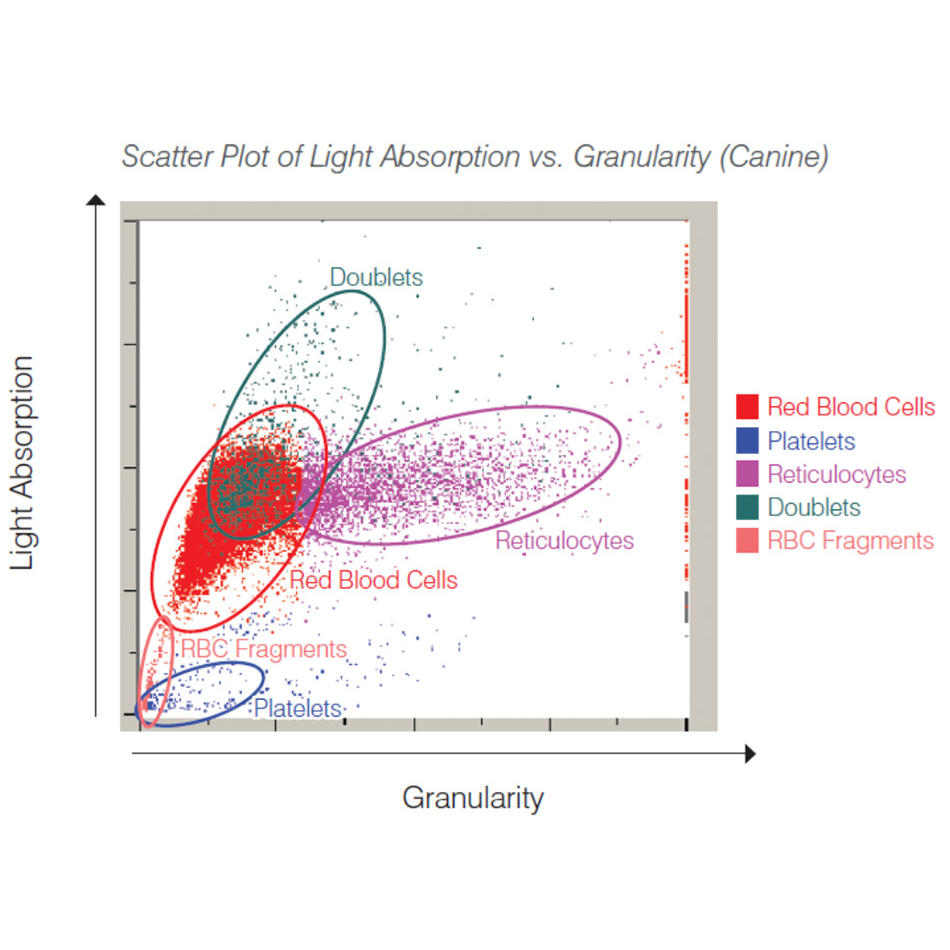

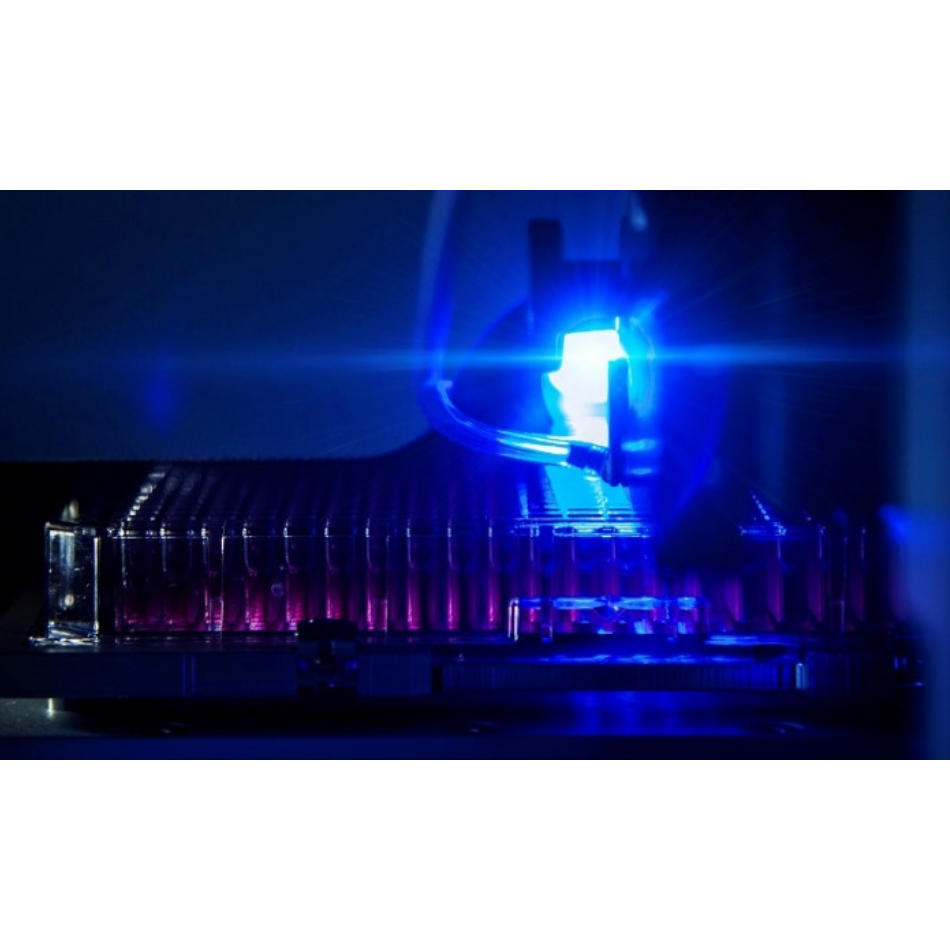

Of course, not all life science instruments are fiber-based. Flow cytometry is a standout example where multiple lasers are shaped and focused by conventional (free space) optics. (If you’re interested, we've written more about flow cytometry.) So next we set out to address the needs of this important application with a new type of laser engine. We called it CellX since the biggest application for flow cytometry is immunophenotyping.

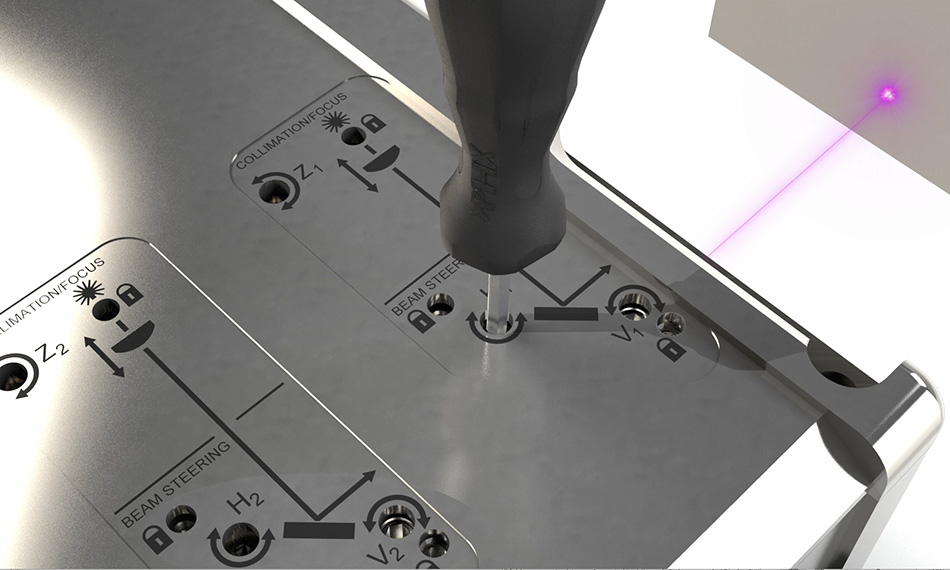

CellX gives users the choice of up to four different wavelengths. It includes the lasers themselves plus all the miniaturized optics needed to create the focused elliptical beam shape needed in a flow cytometer. Some instrument builders are even combining two of these modules to get eight wavelengths for the latest trend called multiparameter flow cytometry. To integrate CellX into one of their instruments, OEM users simply remove the sleek looking lid to reveal a set of screw adjustments giving independent control of the focus and placement of each beam.

Looking to the future

So what’s next? Well how about something that combines the advantages of fiber with the performance of free-space optics. What does that mean? One of the great things about fibers is they stay permanently aligned – it’s just a single piece of glass. And it turns out that alignment stability is a big problem in the field for some instrument OEMs using free-space optics. Depending on how their instruments are handled and used, they may get called out on a service visit every 6 months, just to re-align the laser beams. That’s because conventional optics mounts consist of metal pieces and tiny screws that inevitably get shifted out of their precise alignment at some point.

Coherent has many laser products that go into all kinds of demanding applications including industrial production lines. These routinely deliver many thousands of hours of maintenance-free operation because they're built using proprietary PermAlignTM technology. With this approach, Coherent doesn’t use mechanical optics mounts - instead each optic is aligned and permanently bonded in place. This delivers unmatched ease of use and reliability, as there’s nothing to adjust and nothing to get misaligned.

Visit here to see the next-generation that uses this same PermAlign technology, not just for building lasers but also for delivering the beam you need in your OEM application, eliminating the tiresome and costly problem of field realignment and downtime. The end result: Happy instrument builders, happy instrument users.

Bottom line — when using multiple lasers for any application, simplicity is key and Coherent laser engines are designed to deliver exactly that.

Learn more about Galaxy, CellX, and other laser engines.