Bringing Lasers in Line

Learn why a Powell lens is the most effective way to transform a Gaussian laser beam into a uniform line.

January 04, 2024 by Coherent

Most lasers emit a beam with a circular or elliptical cross-section. When a beam like this hits a flat surface, it makes a small round spot. But there are many instances where it’s more useful to have a line of laser light. For example, projected laser lines are often used as alignment references in construction, manufacturing assembly processes, and even when positioning patients in CAT scanners and other medical imaging systems. They are also used for beam shaping in flow cytometers.

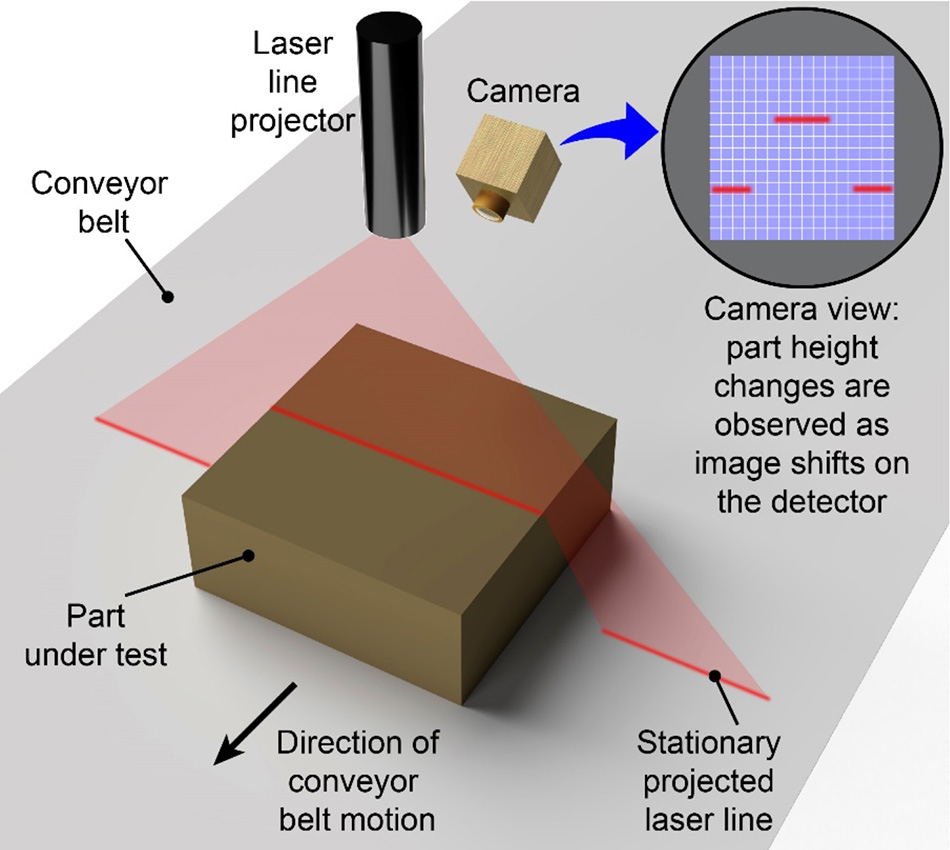

One important commercial application for laser lines is in machine vision systems. These are used to perform automated measurement of part shape and dimensions. The basic elements of a machine vision system of this type are shown in figure 1.

Figure 1: Basic elements of a machine vision system utilizing a laser line. When viewed by a camera at an angle to the beam, variations in part height are seen as shifts in the line position on the camera’s detector.

The laser projects a line onto the part, and a camera views this projected line from an angle. Displacements in the line as seen from the point of view of the camera are then used to calculate the height profile of the object using geometrical formulas.

This technique is frequently employed to inspect parts moving on a conveyor belt. The laser line remains stationary, and the parts move through it. This makes the laser line scan across the entire length of the part. This allows an entire three-dimensional shape profile of the part to be measured.

For machine visions systems of this type, it’s very helpful if the laser line has uniform intensity along its entire length. This simplifies the task of analyzing the image and getting accurate, quantitative data from it.

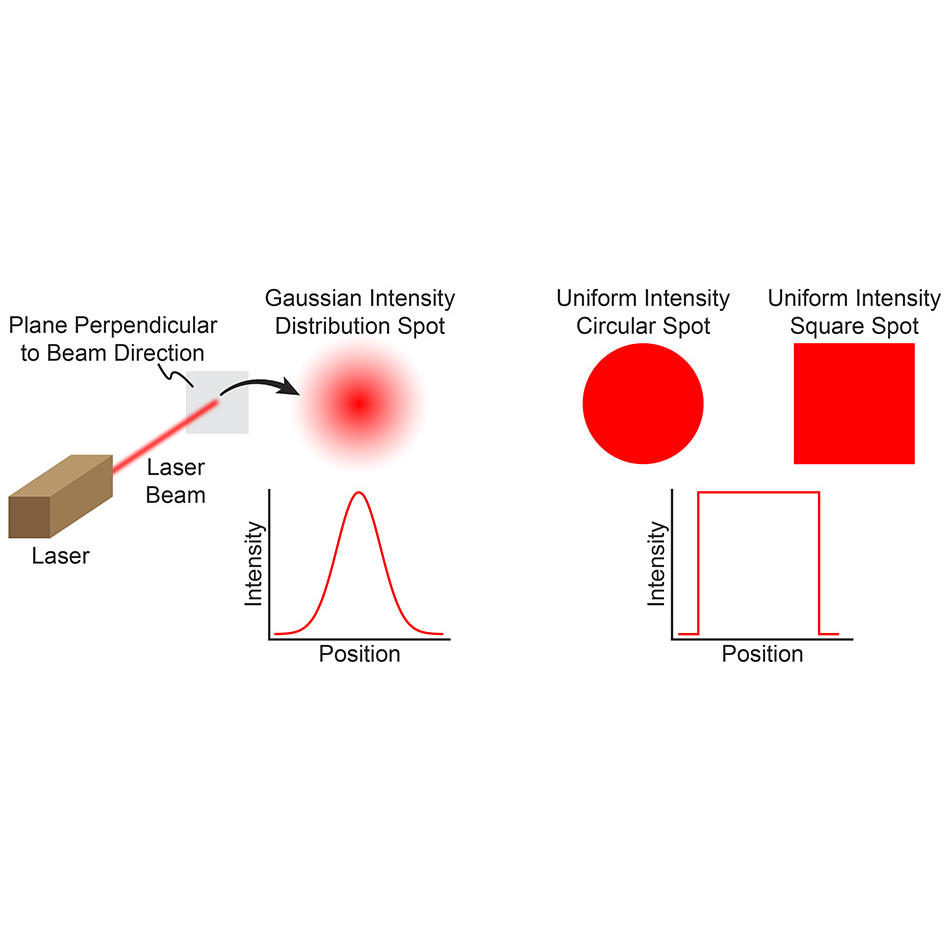

However, most lasers produce a so-called “Gaussian beam” which is much brighter at the center than at the edges. And one unique property of Gaussian beams is that when they’re focused, expanded, or otherwise reshaped using traditional optics, they maintain their Gaussian intensity profile. It’s actually quite difficult to get rid of it.

The Powell Lens

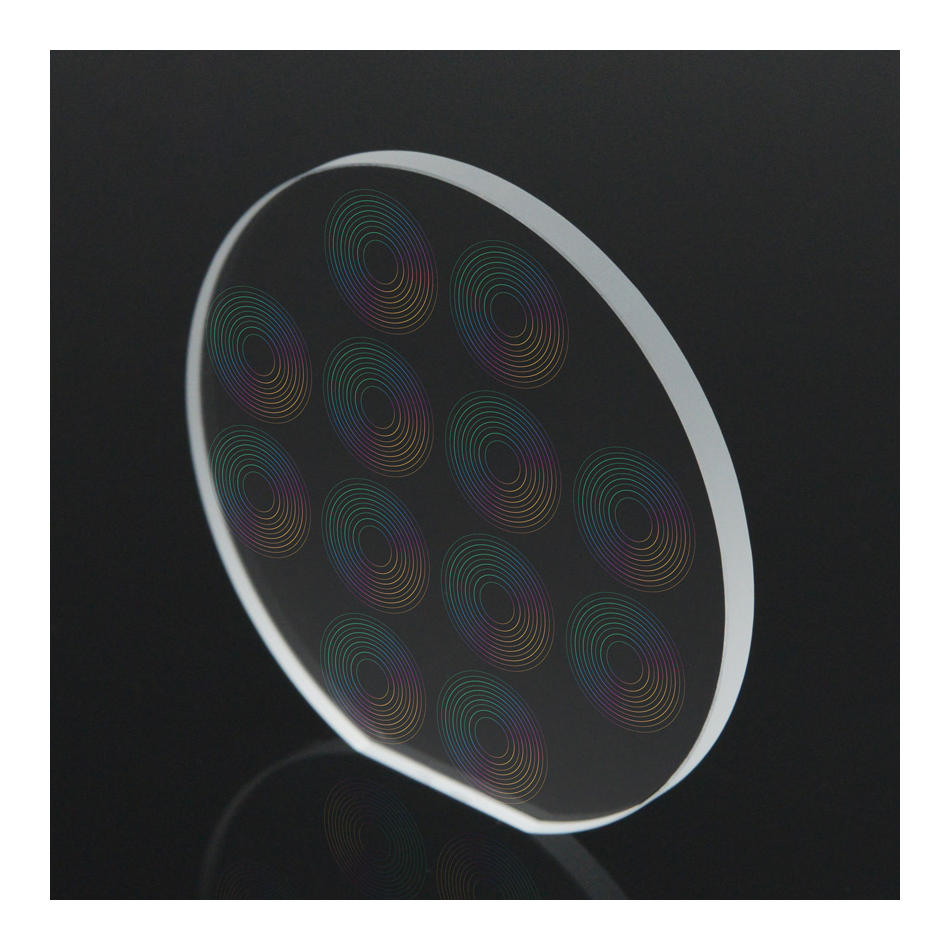

One very clever and effective way of transforming Gaussian beams into uniform-intensity laser lines is the Powell lens (named after its originator, Dr. Ian Powell). The Powell lens is an aspheric cylindrical lens.

The Powell lens takes a circular laser beam and causes it to fan out in one dimension. This makes the beam form a line, rather than a spot, when it hits a flat surface.

The shape of the Powell lens is designed specifically to redirect laser light from the center to the edge of the beam. This eliminates the central “hot spot” and transforms the Gaussian beam into a uniform intensity beam, also called a “top-hat” profile.

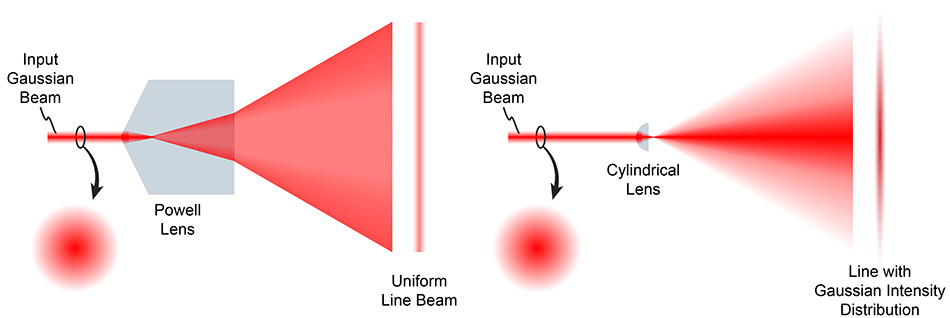

The drawing shows the cross-sectional shape of a Powell lens and compares its operation to a traditional cylindrical lens (which also produces a line but maintains the Gaussian intensity profile).

Figure 2. The Powell lens (left) is compared to a traditional cylindrical lens (right). Both optics transform a round Gaussian profile laser beam into a diverging fan of light which makes a line on any surface on which it is projected. The Powell lens shifts light from the center to the edge of the beam to produce a uniform intensity line, while the cylindrical lens maintains the Gaussian profile of the beam, so its line is much brighter in the center.

There are other methods besides the Powell lens for transforming Gaussian beams into uniform lines, including diffractive optical elements and lenslet arrays. But none of these offer the same optical efficiency (meaning less of the laser light ends up in the line), and none deliver a beam that is as well homogenized in intensity.

Another useful characteristic of Powell lenses is that they are fairly insensitive to input wavelength. This is a big advantage over diffractive optical elements, which are quite wavelength-specific.

This property allows Powell lenses to be combined with diode lasers to make very compact, low-cost line generators. Diode lasers typically exhibit significant unit-to-unit variations in wavelength, and their bandwidth and wavelength vary with temperature, as well. But the wavelength insensitivity Powell lenses enables their use with diode lasers without the need to wavelength select or bin them.

Buying Powell Lenses

It’s difficult to make the cylindrical asphere on a Powell lens, and getting it right takes specialized equipment and expertise. As a result, the quality of Powell lenses varies between manufacturers.

Typically, the user specifies the input beam diameter, wavelength, and “fan angle” needed for their application. The optics manufacturer chooses or creates a Powell lens design that matches these requirements.

Of course, actual parts will have tolerances that lead to unit-to-unit performance variations. For most applications, the performance criteria of greatest importance are the uniformity, the “contained power,” and the line straightness.

But not all manufacturers define these specifications the same way. So, it’s important for the buyer to understand how to interpret the information they’re supplied.

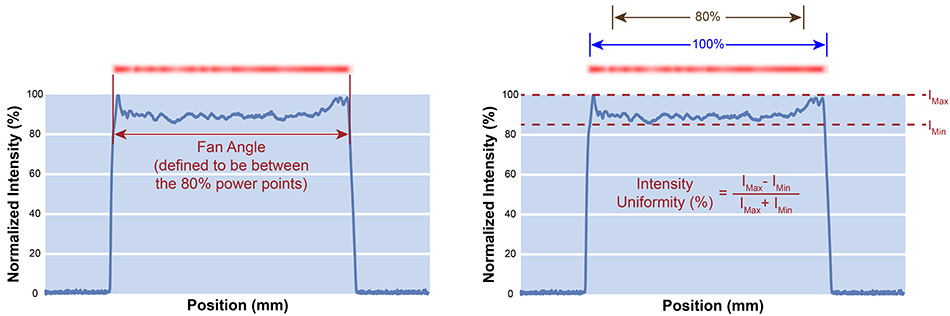

First of all, fan angle is usually defined to be the point at which the power has dropped to 80% of its peak value. This is different than the way laser beam size is usually calculated; the diameter of a Gaussian laser beam is defined the point where the power is 1/e² (13.5%) of its peak value. But, of course, the whole point of the Powell lens is that it doesn’t produce a Gaussian beam.

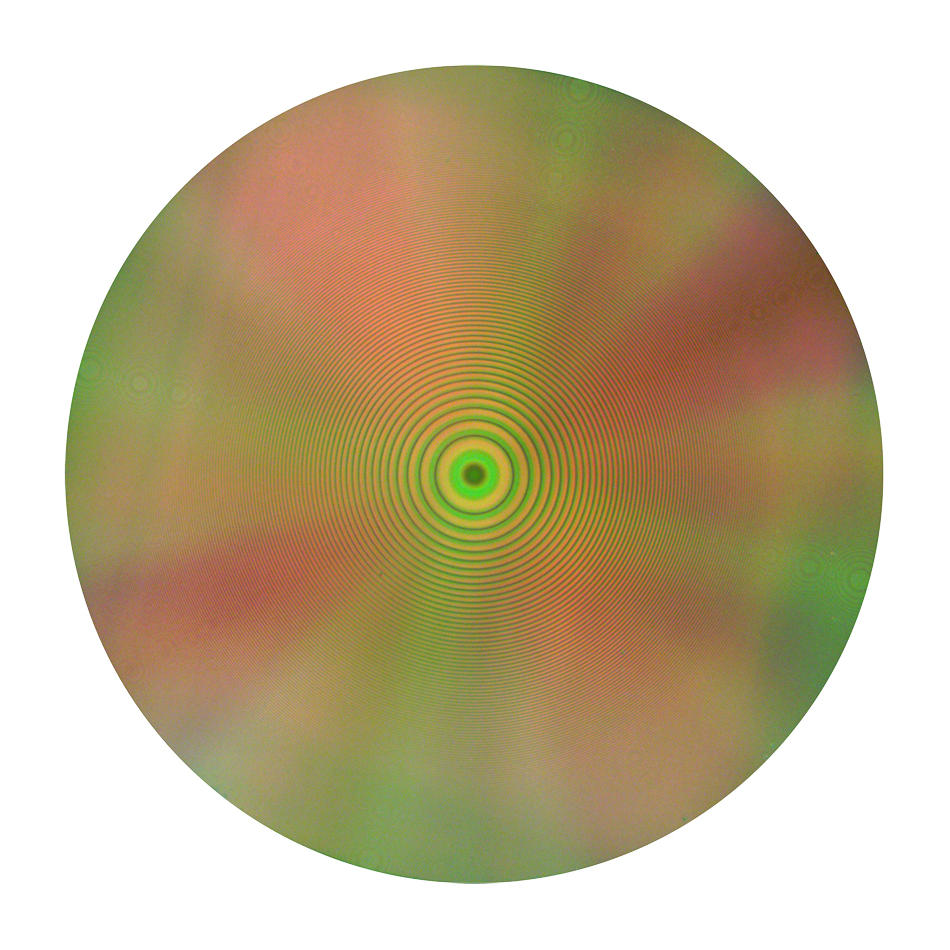

Figure 3. Power lens fan angle is usually measured from the points at which the intensity has dropped to 80% of its peak value. Intensity uniformity is specified differently by various manufacturers.

However, the intensity uniformity of the line (given by the formula in the drawing) isn’t always specified the same way. Most importantly, many manufacturers only apply their intensity uniformity to the central 80% of the line (indicated in the drawing), rather than all the way to the edge (100%). But excluding the edges of the beam creates an unrealistic picture of actual performance, because this is where non-uniformities are typically most pronounced.

Coherent uses the more stringent 100% criteria for our uniformity specification. The result is that Coherent Powell lenses deliver better measurement accuracy, signal-to-noise ratio, and unit-to-unit consistency. Learn more about high-performance Coherent Powell Lens and the benefits they bring to machine vision, life sciences, and more.