WHITE PAPER

Simplifying Access to High Energy sub-5-fs Pulses

High pulse energy and long-term stability from a one-box Coherent Astrella ultrafast amplifier, together with a novel hollow fiber compressor and a turnkey compressor/measurement d-scan system, provide a simpler route to ultrashort (sub-5-fs) pulses.

Overview

In order to make ultrafast pulses accessible to the broadest possible field of applications, Coherent has been implementing a comprehensive program of design methodologies, materials qualification and sourcing, and HALT/HASS testing protocols that go under the name of the Industrial Revolution in Ultrafast Science. This approach emphasizes performance, operational simplicity, repeatability, and reliability. Astrella kilohertz amplifiers are standout examples of this revolution, providing the first turnkey access to pulse widths as short as 35 fs with pulse energies approaching 10 mJ in the latest models. Yet several important emerging applications in physics, photochemistry, and materials science need even shorter pulses and/or higher peak powers – for example, to generate attosecond X-ray pulses or create bursts of relativistic electrons. In this article, we show how Professor John Tisch and Dr. Daniel Walke from Imperial College of London, have collaborated with Coherent and Sphere Ultrafast Photonics to exploit the turnkey simplicity and stable beam quality from an Astrella amplifier to reach 5 fs pulse widths with pulse energies as high as 2 mJ. This was achieved by combining the Astrella with a next-generation hollow fiber pulse compressor (HFC) and a hands-free pulse compressor/measurement d-scan system. This relatively simple and compact system thereby provides straightforward access to a pulse width/peak power regime that was until recently only available in a handful of specialist laser labs.

Astrella Integrated Amplifier

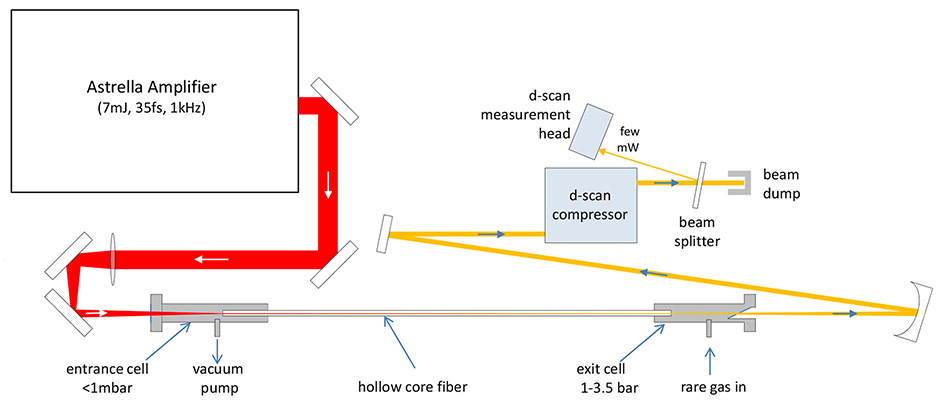

This demonstration was carried out at the Coherent facility in Santa Clara. As summarized in figure 1, the three key components in the experimental setup are an Astrella amplifier, a custom HFC from the Tisch group to broaden the bandwidth, and a compressor/metrology dscan system from Sphere Ultrafast Photonics to simultaneously measure and optimize (i.e., recompress) the final output pulses.

Figure 1. Experimental set up for 5 fs pulse generation and measurement. The output of a Coherent Astrella amplifier is focused by a lens (f=1 m) into a 250 μm inner-diameter, differentially-pumped hollow core fiber, pressurized with either neon or helium gas. The pulse energy from the Astrella was controlled over the range 0-7 mJ with a waveplate-polarizer combination (not shown). The spectrally-broadened output from the hollow core fiber is re-collimated by a concave silver mirror (f=0.75 m) before it is both compressed and measured by the d-scan blue system. Only a few mW of average power is required for the d-scan measurement head, so beamsplitters are used to sample the watt-level (~1 mJ @ 1 kHz) beam from the hollow fiber. The beam entering the beam dump would in general be available for experiments.

The Coherent Astrella is an example of the latest generation of one-box Titanium:sapphire ultrafast amplifiers; Astrella is capable of producing over 7 mJ per pulse at a pulse width < 35 fs, a wavelength of 800 nm, and a repetition rate of 1 kHz. All the laser components are located in the compact (26 cm x 79 cm x 125 cm) head. These include a one-box Vitara oscillator, a pulse picker, stretcher, and a regenerative amplifier pumped by a Coherent Revolution Q-switched Nd:YLF laser, and an output compressor. This particular architecture is ideal for optically demanding applications such as the work described here because of the beam quality and stability that can be achieved with a stable regenerative amplifier cavity (versus a multipass amplifier, for example). A symmetric Gaussian beam and stable beam pointing are needed to enable tight focusing into the small entrance aperture of the hollow core fiber – to ensure stable HFC output and to avoid causing damage to the fiber. The Astrella beam quality measured during these experiments was M² < 1.04.

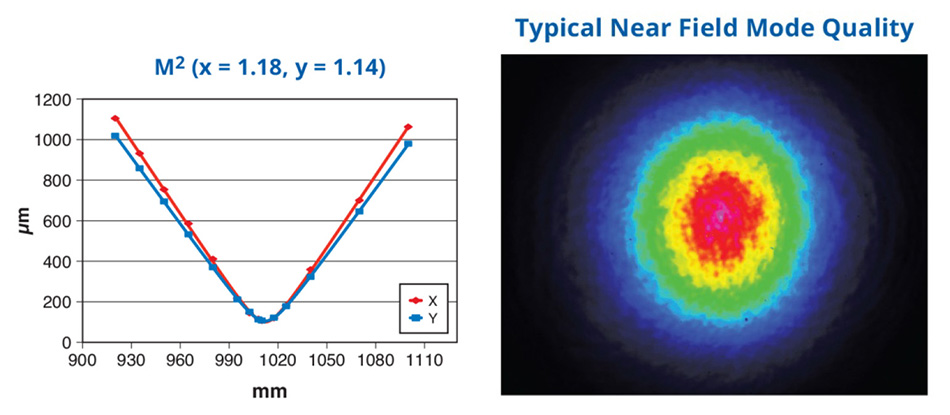

Figure 2. The integrated Astrella amplifier is characterized by its low M2 output beam, high pointing stability, and low output noise. The inset shows typical near-field M2 data.

The stability, reliability, and beam quality of Astrella were maximized as part of Coherent’s ongoing Industrial Revolution in Ultrafast Science, where we apply methods, materials, and practices long-proven in our industrial lasers; these lasers are used in applications where 24/7 operation and low-maintenance requirements are absolutely critical to high throughput manufacturing processes. This necessitates a comprehensive and relentless approach to laser stability and reliability. For example, we select Astrella materials to have low outgassing properties at any operating temperature and when exposed to laser light.

Just as important, the design and manufacture (and even the shipping!) of Astrella, its optomechanical components, and every sub-system, have all been optimized using HALT/HASS protocols. Widely used and respected in other technology fields, Coherent has pioneered the use of HALT/HASS quantitative methods in the laser industry – see side-bar.

As a result, Astrella features low output noise (0.5% rms) and drift and unmatched beam pointing stability (<10 µrad rms): it can operate untouched for long and complex data runs, even 2D and 3D spectroscopy studies spanning several days.

Optimized Hollow Fiber Compressor

In this demonstration experiment, the output pulses from an Astrella amplifier (35 fs pulse width and 1 kHz repetition rate) were focused into a HFC. This takes advantage of the spectral broadening caused by self-phase modulation (SPM) in a hollow fiber containing a noble gas. The fiber acts as a dielectric waveguide, confining the beam and allowing for a long interaction length at a high intensity. This established approach is proven to allow the generation of highpower (up to 5 mJ), few-cycle laser pulses at kHz repetition rates.

A differentially pumped hollow fiber was used here. As pioneered by Tisch and others, differential pumping uses the low gas conductance of the hollow fiber capillary to maintain a pressure gradient along the fiber through differential pumping and keep a vacuum at the entrance. This reduces plasma formation at the fiber entrance where the laser intensity is highest. (In a statically gas-filled hollow fiber, plasma formation at the input side would otherwise cause a reduction in both coupling efficiency and shot-to-shot stability, by altering the size and position of the focus at the entrance from its optimum.) As shown schematically in figure 1, a separate gas-filled (helium or neon) cell at the exit of the HFC allows a differential pressure gradient to be established along the fiber while maintaining the vacuum (<1 mbar) in the entrance cell.

In these experiments, the Astrella output pulses were focused by a 1 m focal length, broadband anti-reflection coated lens and directed, without any active stabilization, into the entrance of a 1 m long hollow core fused silica fiber (of inner radius a = 125 µm) housed inside an evacuated cell, via a 0.5 mm thick fused silica AR coated entrance window. The Gaussian beam waist at the focus was measured to be ~160 µm, satisfying the condition w0 = 0.64a for optimal energy coupling into a hollow core fiber and resulting in focal spot intensities on the order of 1014 W/cm2. The exact intensity depends on the pulse energy, which could be tuned continuously in the range 0.5 - 7 mJ by means of a λ/2 waveplate, which was temporarily placed before the compressor of the Astrella system in these experiments. The system was able to run continuously over each day of the campaign without any active feedback or re-alignment by the users due to the combination of the high-stability input beam from the Astrella amplifier and a differentially pumped hollow fiber.

In the case of neon, SPM in this HFC setup resulted in a bandwidth covering the range 550 - 1000 nm. After exiting the gas cell via a 0.5 mm fused silica Brewster window, these broadband pulses were then both compressed, and their complete temporal and phase profiles determined using a d-scan blue (Sphere Ultrafast Photonics, Porto, Portugal) system.

d-scan Pulse Compressor/Pulse temporal measurement

There are several approaches that can characterize various aspects of femtosecond pulses but the d-scan blue unit used in this demonstration offered a number of advantages, including its ability to measure and compress pulses in the few-cycle regime with world-record durations (down to single-cycle pulses). The overall ease and speed of use makes d-scan the perfect tool for HCF measurement and optimization. First, it can perform both the compression/control and temporal measurement in a single unit. Second, it is a robust self-contained tool that is very tolerant of input beam misalignment (even ± a few degrees) and therefore quick to set up. Third, it is fast, providing a complete pulse characterization (phase and amplitude) in less than 1 minute for kilohertz pulse repetition rates. In addition, the user has the option of push-button optimization to yield the shortest possible pulse width, without needing special pulse metrology expertise.

Furthermore, the d-scan method can provide the more demanding user with a detailed pulse characterization dataset. For example, the user can output plots of all the key wavelength, phase, and intensity parameters, providing plots of intensity vs. wavelength, intensity vs. time, phase vs. wavelength, and phase vs. time. The d-scan instrument can thus reveal if there is any pulse breaking and also record the full phase of the pulses, i.e., its residual dispersion to all orders including third-order dispersion (TOD) and fourth-order dispersion (FOD).

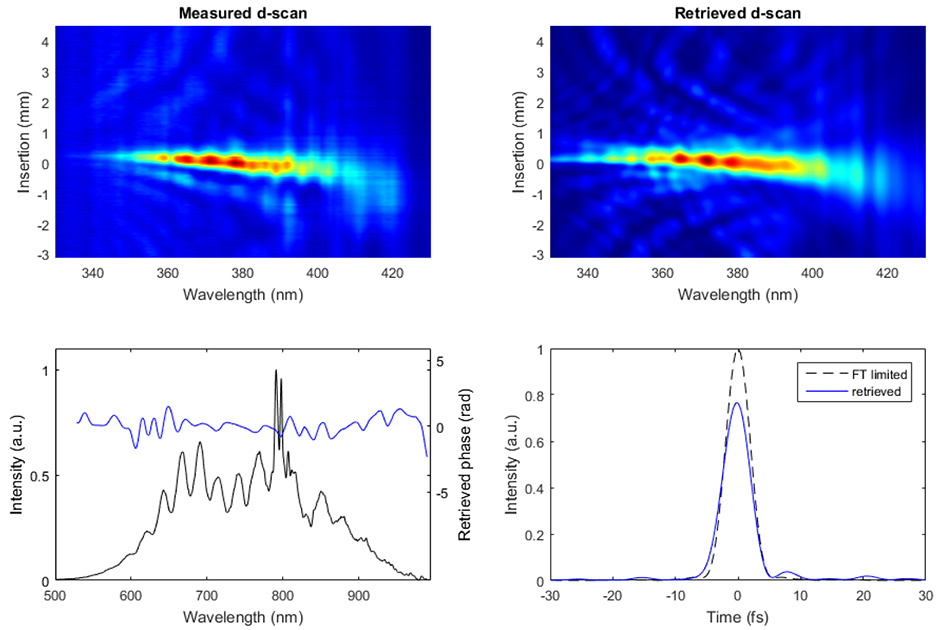

Like other pulse temporal measurement methods, the d-scan device uses optical effects to convert phase information into an amplitude signal that can be sensed on a photodetector array. The d-scan modules tailored for an HCF system comprises a chirped mirror compressor including a pair of thin glass wedges on translation stages, providing both positive and negative dispersion. After the pulses pass the compressor, a small portion undergoes second-harmonic in a nonlinear crystal and the resulting spectrum is measured as a function of the introduced dispersion, which enables online monitoring of the pulses. By measuring the spectrum of the nonlinear signal for different input phases (glass insertions) around the point of maximum compression, a two-dimensional trace (d-scan trace – Fig.3 “measured”) is obtained that enables the full retrieval of the spectral phase of the pulses via an iterative algorithm (Fig.3 “retrieved”). In operation, the d-scan unit automatically scans the glass wedge dispersion around the optimum compression value, i.e., the shortest obtainable pulse width. Internal algorithms then process the SHG spectra and derive a complete phase/intensity/wavelength/time data set.

Discussion of Preliminary Data

In a first suite of experiments using this set-up, the researchers demonstrated sub-6-fs pulses with HFC output energy of 0.7 mJ, when using an input pulse energy of 1.5 mJ. They identified that this output power was limited by ionization in the neon gas. Increased output power can be achieved using helium as the nonlinear medium, which has a greater ionization potential but also has a lower nonlinear index, i.e., lower SPM efficiency. Using 3.4 bar (at the HFC exit) of helium as the nonlinear medium, they then achieved 6 fs pulses with a HFC output energy of 2 mJ, using an input pulse energy of 5 mJ. Tisch notes that greater output energies would be possible in the future by using a larger diameter HFC, which enables the amount of transmitted energy to be increased without increasing the intensity within the fiber.

Figure 3. Top (left): Measured and (right): fitted d-scan data of compressed pulses using a differentially pumped hollow fiber (250 micron diameter by 1m long) pressurized to 3 bar at the exit end with neon gas. The input laser pulse energy was 1.5mJ (1.5W at 1kHz pulse repetition rate) and the output pulse energy was 0.77mJ. Bottom (left): pulse spectrum and retrieved spectral phase; (right) Output pulse in the time domain, Fourier transform limited pulse and retrieved pulse, revealing a duration of 5.1 fs FWHM.

Pulse data set |

|

Retrieved pulse FWHM |

5.1 fs |

Fourier transform limited FWHM |

4.5 fs |

Relative Peak Power |

76.5% |

Table. Summary of pulse analysis for the data set shown in figure 3. The relative peak power is the peak power of the compressed pulse compared to the ideal Fourier transform-limited pulse.

Figure 3 shows some typical data from the neon-filled HFC setup with the overall pulse parameters summarized in the accompanying table. The figure shows the measured d-scan data and the “retrieved” d-scan trace obtained from the proprietary iterative algorithm of the dscan blue system. These particular data show the effect of some residual third-order dispersion (TOD), in the range 40-60 fs2 , as evidenced by the small tilt in the d-scan trace, resulting in a relative peak power of 76% compared to ideal (Fourier-limited) compression. The researchers expect to obtain lower TOD, shorter pulse widths, and higher peak powers by optimization of the HFC parameters and careful dispersion management, using for example a water cell, in the next set of experiments. The ease of use of the d-scan system allowed the researchers to quickly scan through the parameter space for the HFC system (e.g. changing gas pressure and input pulse energy) while monitoring the output pulse. This provides a straightforward method for optimizing the performance of such HFC systems.

Professor Tisch explains the context of these first results, “Most hollow fiber users are injecting around 1 mJ into their fibers. This is the typical energy limit if differential pumping is not employed, i.e., if the hollow fiber is filled with a uniform gas pressure. Only a small number of groups are operating HFCs significantly above 2 mJ, and those that do rely on differential pumping. I think it’s also important to note that in this campaign we could couple 5 mJ into a standard fiber without any special fiber input adaptions (as used by some other groups) with reasonable efficiency and without damaging the hollow fiber. This is testament to the superb beam quality and high beam-pointing stability of the Astrella.”

Summary

The brief history of ultrafast laser pulses shows that advances in lasers and related technologies enable routine access to ever-shorter pulse widths and higher peak powers. This simple access is key to moving these pulses from the specialty laser lab out into the broadest possible spectrum of scientific disciplines, from cell biology to particle physics. Today, amplified 35 fs pulse widths at the millijoule energy level are already approaching push-button simplicity in the latest generation of integrated amplifiers, such as Astrella. The work described here hopefully points the way forward to another ultrafast milestone, where high-power sub-5-fs pulses can be routinely used in diverse but equally important branches of scientific research.

Sidebar

The Impact of HALT/HASS on Laser Stability and Reliability

Careful material choices and better optomechanical components and system design are only part of the reason for Astrella’s unmatched reliability and stable operation. Astrella was designed and optimized using an engineering protocol called Highly Accelerated Life Testing (HALT). This is a proven approach that takes initial component and system designs and makes them better through pushing components and systems to failure, analyzing the failure mechanism(s), designing out the failure cause, and then iteratively repeating the harsh testing until all identifiable failure mechanisms are eliminated.

We then use the results of HALT to develop an effective final screening protocol (HASS is Highly Accelerated Stress Screening) that weeds out product manufacturing weaknesses or errors, without decreasing the useful life of the units that are shipped to customers. In addition to other tests, assembled Astrella lasers are subjected to a rigorous pre-programmed routine of fluctuating vibrations and sudden temperature shifts in this chamber. Any Astrella whose performance changes in any measurable way at the end of the HASS tests is rejected for shipment.

Evidence from numerous industries confirms that successful HALT/HASS require complete immersion. Coherent is proud to be the first manufacturer of scientific lasers to invest in the testing hardware and software for HASS certification; the environmental testing chamber alone represents a substantial capital investment. With Astrella, we’ve proved that after several HALT iterations and final HASS checking, even a product as complex as an ultrafast amplifier eventually yields to this relentless improvement and delivers extreme reliability and longevity.