Medical Device Manufacturing (MDM)

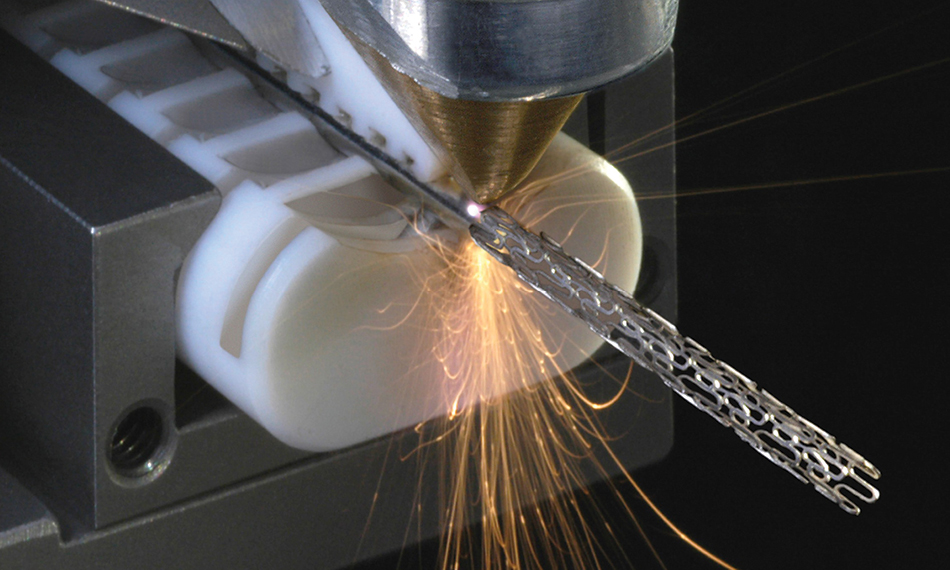

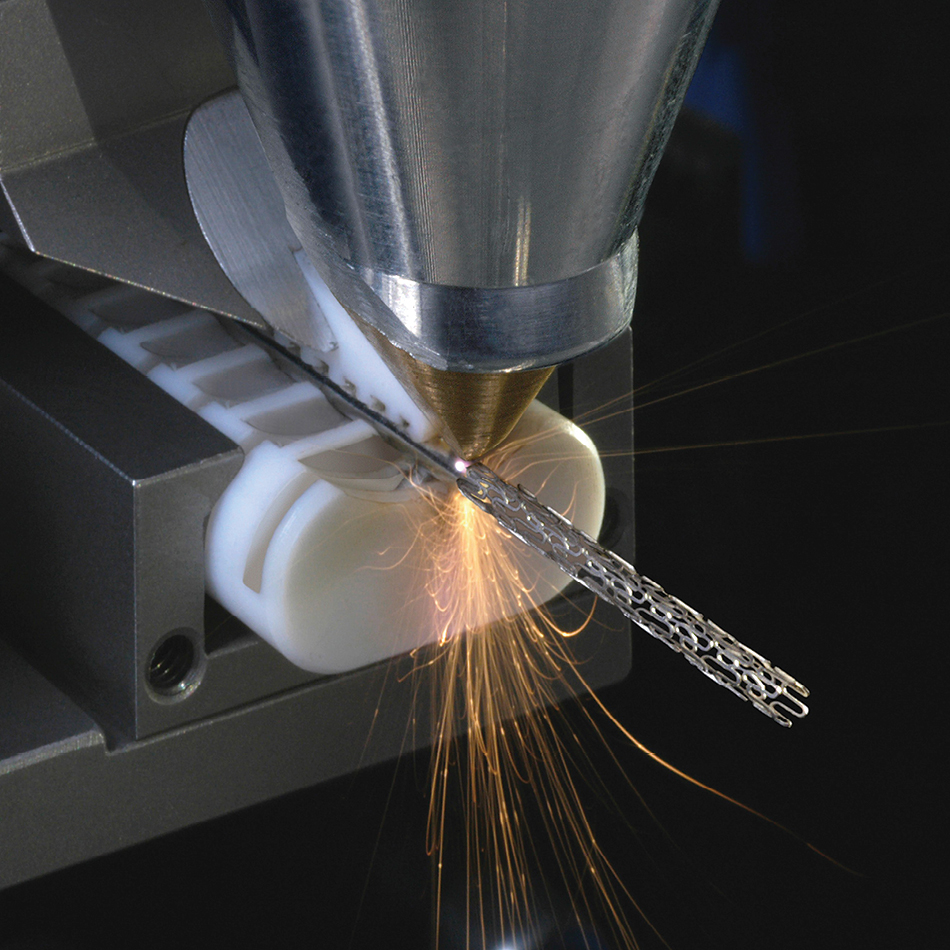

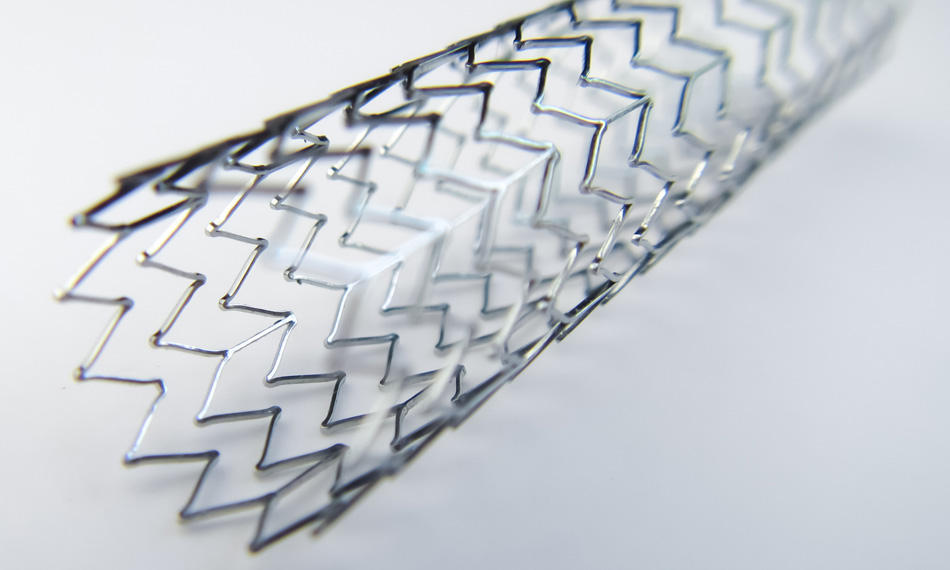

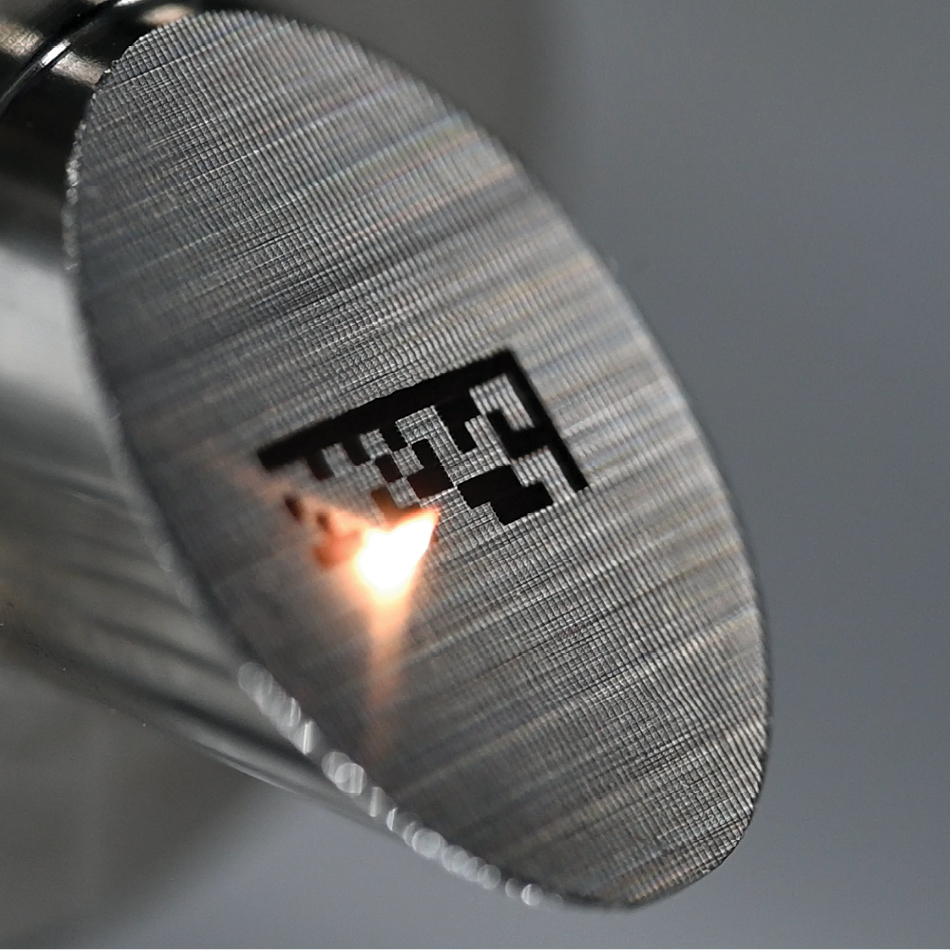

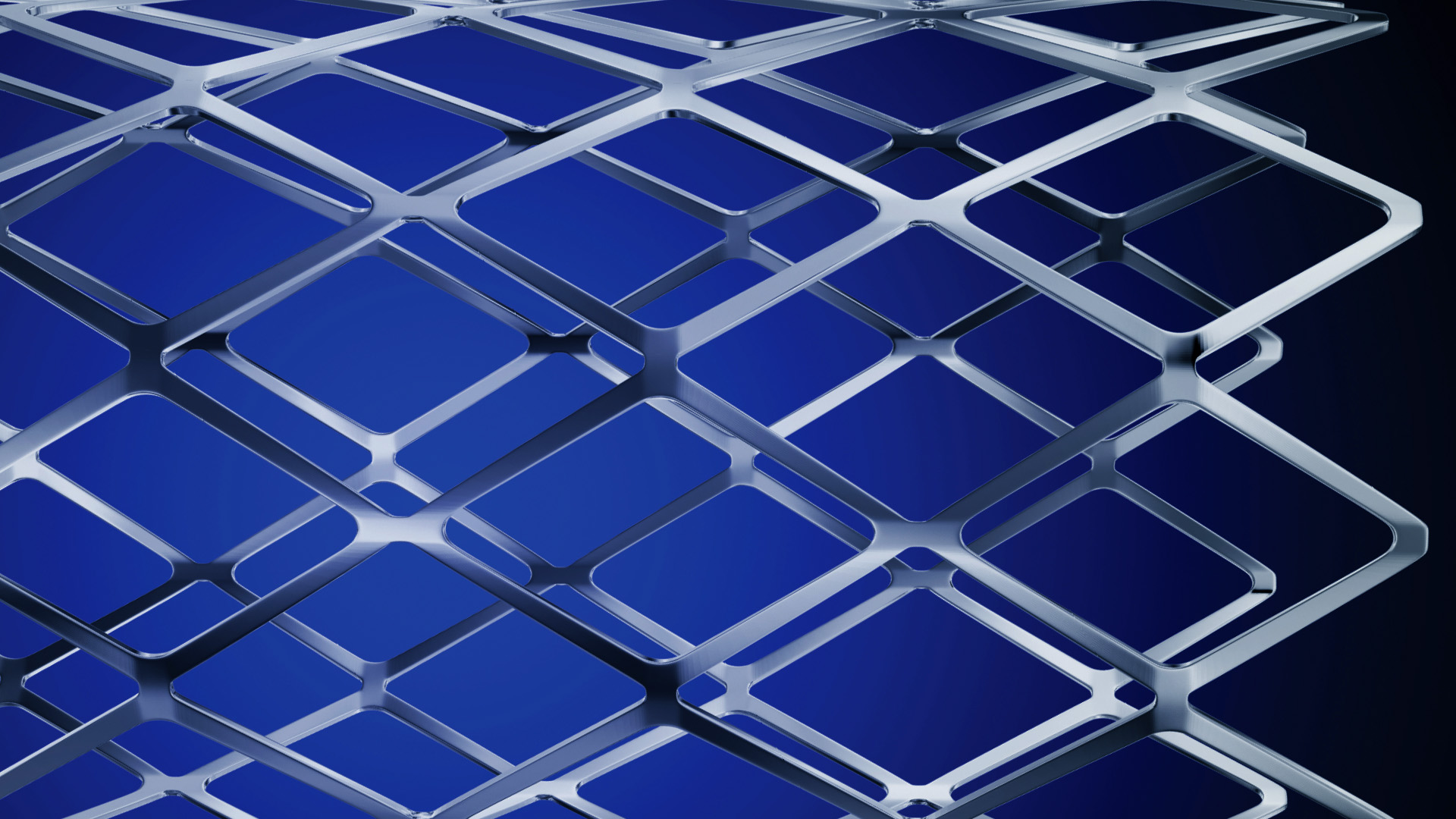

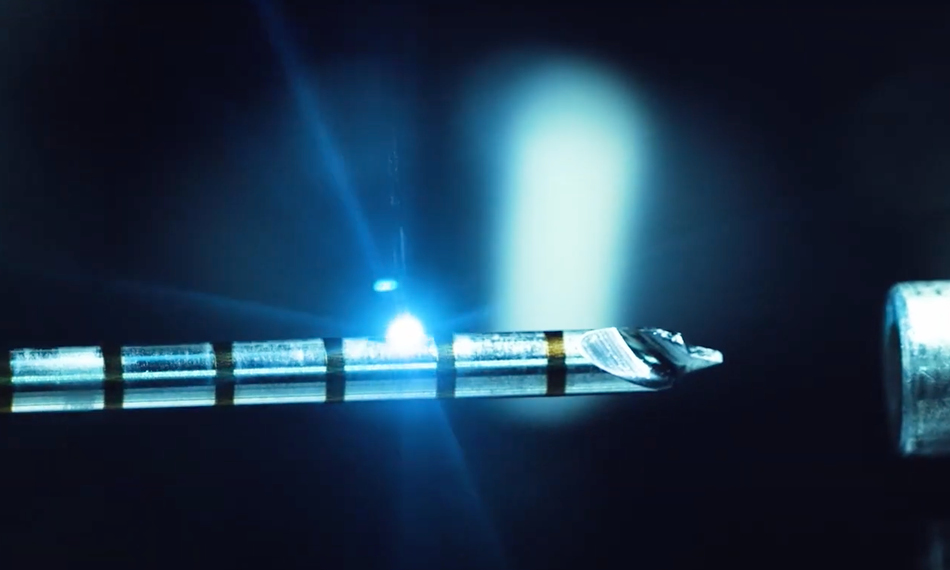

Rely on laser-based welding, cutting, marking, and drilling machines for high-precision MDM in diverse metals and plastics.

- Precision Results Get better results with our precision machines and decades of process knowledge.

- Maximum Uptime Maximize your productivity thanks to superior reliability backed by local service.

- Optimum Solution Get the best solution from the company with the broadest laser portfolio.

Laser Precision

Advances in minimally-invasive procedures and robotic surgery are driving developments in MDM that often require increasingly miniaturized devices and/or device details. Laser machines offer both the precision and process versatility to support small batches with frequent changes as well as high volume automated runs of identical parts. And whether you’re cutting, welding, drilling, or marking in MDM, whatever the materials, our complete range of laser technologies means we have the optimum solution for your needs.

Let's get started

Please submit some information about yourself, and a product expert will contact you within 2 business days.

By providing your information and clicking ‘Subscribe’, you opt-in to receiving periodic email marketing communications from Coherent Corp. and understand that your personal data will be processed in accordance with our Privacy Policy and that our Terms apply. You may opt-out of marketing emails sent by us at any time by clicking the unsubscribe link in any marketing email you receive.

Product Applications

More Featured Assets

Medical Device Products

Global Customers

Resource List

Ready to Get Started?

Share your contact info and a specialist will reach out.

By providing your information and clicking ‘Subscribe’, you opt-in to receiving periodic email marketing communications from Coherent Corp. and understand that your personal data will be processed in accordance with our Privacy Policy and that our Terms apply. You may opt-out of marketing emails sent by us at any time by clicking the unsubscribe link in any marketing email you receive.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.